Flint Group Produces Print Samples To Highlight Flexo Evolution

- Published: April 20, 2017

WILLSTAETT, GERMANY | Flint Group is offering print samples said to demonstrate several ground-breaking technologies to its customers. The samples were produced as a result of a partnership between Flint Group, Soma engineering, and Marvaco Oy.

The print job was done with only six process colors—cyan, magenta, yellow, black, green, and violet in the FlexiPrint MV nitrocellulose (NC)-based ink system for high performance surface print and lamination work. The ink series is said to offer maximized color strength and specific shades to support highest quality and fixed palettte multi-color process work (high definition flexo). FlexiPrint MV is specifically modified for high-speed printing and enhanced press stability throughout the entire job to support maximized Overall Equipment Efficiency (OEE).

The plate of choice was the nyloflex ACE Digital due to its performance in combination with new technologies, reportedly providing excellent reproduction of flat top dots and surface screenings. The plates are specialized for printing of flexible packaging. Their high solvent resistance makes them perfect for use with solvent-based inks. Extremely durable for long print runs, the plates also offer advanced cleaning behavior, leading to fewer press stops.

Flint Group’s rotec Bluelight Sleeves are light and robust, setting the benchmark in conventional plate mounting. Available in wall thicknesses from 0.9mm to 125mm, the sleeves are said to offer superior service life and outstanding durability. XXL dimensions for wide web presses are also available.

The job was printed on a Soma Optima2, a wide web CI flexographic press recently launched at drupa. The press offers five unique solutions: Zero Meter set-up waste, Advanced Bounce Control, investment flexibility, online press supervision, and unexpected ink savings.

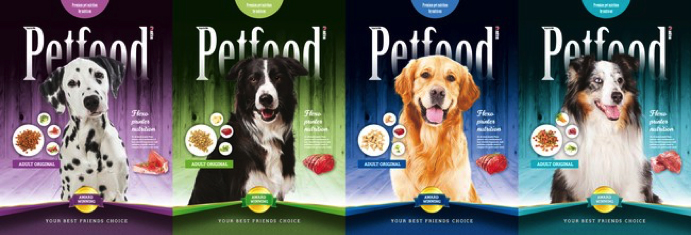

The design and prepress work was produced by Marvaco Oy and included the Marvaco EGP (Expanded Gamut Printing) Evolution technology, allowing the production of PMS shades without using any spot inks (fixed palette from four to seven process colors). Product images with ultra-high line screen density (100 lpcm, 254 lpi) and high densities (+20%) were achieved thanks to flat top dot technology and Marvaco’s micro surface structure on the plate. The print samples demonstrate photograph sharp images with very small, round dots and large gamut, where strong solids are combined in the same color with limitless fade-outs to 0%.

For more information or to request a print sample, contact Deanna Klemesrud at This email address is being protected from spambots. You need JavaScript enabled to view it..