Embedded Control

- Published: May 31, 2004, By by John MacDonald, Rockwell Automation

Drives and controllers come together to meet user demands for high performance, greater flexibility, and cost-effective control.

Increased demands for greater productivity and efficiency continue to spur advancements in control technology. Not only are today's converting processes becoming faster, the time frames for implementing control systems are decreasing. The new industry mandate: Control systems must be high performance, cost-effective, and easy to integrate and maintain.

Driven by the increased speed and power of today's semiconductors and microprocessors, automation control systems have undergone considerable transformation over the past several decades. Today's high-performance microprocessors have allowed control systems to evolve from the early years of using relay logic to high-performance, multi-tasking digital controllers. But, along the way, this shift has presented a host of challenges, including more complex system architectures and the added expense of supporting multiple platforms.

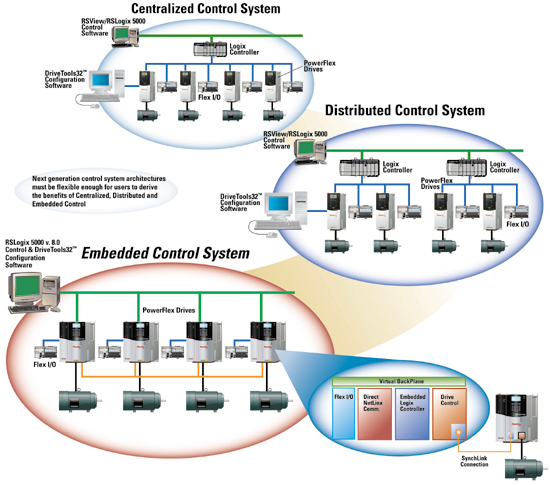

To accommodate complex applications and augment limited processing and communication capabilities, control engineers leveraged various centralized and distributed control system architectures.

For centralized control, the logic and sequential control take place in a central controller. Centralized control also can take place at the drive, while inner loop control takes place. For distributed control, the logic and sequential control take place in local controllers. Drives are connected locally, limiting network communications and required bandwidth, while drive-based, outer and inner loop control take place at the drive.

Both methods were devised to augment limited processing and communication capabilities and more demanding applications/performance from users. Unfortunately, many of these architectures required extensive programming, specialized tools, and proprietary communication networks. This resulted in system synchronization challenges and applications that were difficult to troubleshoot and maintain.

Variable-speed drives have undergone a similar transformation. Yesterday's motor-generator units have been replaced with today's compact, ultra-performance DSP-based (digital signal processor) drives. Through this evolution, users continued to demand increased capabilities, enhanced flexibility, and improved performance.

What Is Embedded Control?

One of the most significant developments in drive control technology is a system that integrates a standard controller platform into a drive. The result — embedded drive control — offers higher system performance, simpler application development, and lower system costs, often in a space-saving design. This new technology needs to be flexible enough to support both centralized and distributed control architectures.

The use of a standard controller (as opposed to a more complex proprietary processor) is an industry first for intelligent drives. The foundation of this technology is built on the benefits of commonality in development tools, hardware, and networking services to give users the same “look and feel” across multiple platforms, including networks, operator interfaces, programming, and hardware. This makes drives easier to program, implement, operate, and maintain.

What Are the Advantages of Embedded Control?

Embedded control in drives offers a number of benefits, including the following items:

- Higher system performance — The embedded control platform gives users more options to ensure they have the right architecture to meet their application needs. Embedded drive control achieves a high level of performance by eliminating the need to communicate with a central computer. By using a “virtual backplane” rather than a physical backplane, as in a standard controller chassis, control algorithms can be executed locally at the drive, limiting network communications to supervisory and diagnostic functions and enhancing overall system performance.

- Simpler application development — Traditional systems require a dedicated controller for logic and I/O (input/output) control and a separate controller for drive control, all of which require their own software package, hardwiring/communications, and synchronization logic to integrate. With embedded control, the drive can be configured as the master controller of a system and can “own” remotely located I/O connected to the network.

-

Lower system costs — By embedding the controller into the drive, hardware and software system design is simplified, reducing application-engineering efforts. The combination controller and drive also requires less space than traditional control and drive hardware installations, reducing the need for expensive enclosures and limiting the floor space required. Equipment interconnections are eliminated, reducing associated control hardware and improving system integrity.

In converting applications, such as control of a pump or fan, a user would have to mount a separate drive, controller, and other components into an enclosure, wire them together, and configure the appropriate communication network. The embedded control platform eliminates these tasks, resulting in a faster and lower-cost implementation. Coordinated drive applications benefit from the speed of virtual backplane communication and the flexible, open communication interface. In these architectures, a drive can be used as a stand-alone device, communicating to a centralized controller, or in a fully distributed architecture, as an intelligent drive and controller combination.

With a single, embedded drive control platform, hardware and integration costs are reduced with the elimination of redundant components, including I/O, network connections, and programming software. There also is less time required to program, commission, and maintain systems, and troubleshooting is easier because the same programming environment is used for all control functions. In short, embedded drive control greatly simplifies the system architecture. When the architecture and tools are minimized, so is the cost to install and maintain the investment.

John MacDonald is the commercial marketing manager for Rockwell Automation's Global Drives Systems business, Milwaukee, WI. MacDonald has been applying centralized, distributed, and embedded control systems to web handling applications for more than ten years. He can be reached at 262/512-2034 or at This email address is being protected from spambots. You need JavaScript enabled to view it.

The views and opinions expressed in Technical Reports are those of the author(s), not those of the editors of PFFC. Please address comments to author(s).