Model Mock-Ups

- Published: November 30, 2004, By Nsenga Byrd Thompson, Associate Editor

Surface Treating

We’re just a bunch of MacGyvers," jokes Dan Haney, president of the Haney Packaging Resource Ctr. (PRC). Not unlike the popular 1980s T.V. secret agent Angus MacGyver, Haney PRC is not afraid of experimentation to make things work that defy conventionality.

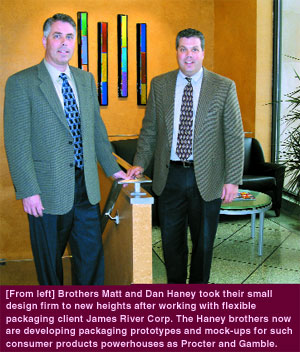

In 1990, fresh off the heels of graduating from Kent State Univ. and the Univ. of Cincinnati, respectively, brothers Dan and Matt Haney used their entrepreneurial spirits and graphic design and business backgrounds to form Haney Design. They provided graphic design services to local and regional clients for collateral materials, print ads, and more.

While working with flexible packaging client James River Corp., the Haney brothers recognized a need in the marketplace for "perfect" package prototypes in small quantities. Over a period of two years, Dan and Matt Haney developed the proprietary technology they envisioned would enable the creation of true-to-life prototypes in any quantity their clients required.

Building from their experience with James River Corp., the Haney brothers took their prototype capabilities to local design firms, as well as to Procter and Gamble and other consumer goods manufacturers. P&G and others embraced the concept, and the Haney brothers knew they were onto something big.

As Haney PRC, the company serves as a comprehensive industry resource after the design process all the way to the full print run. The company currently has 75 full- and part-time employees that represent a variety of skills and experience. New hires will be added over the coming year as business continues to grow, even though the company never has had an active sales force.

Dedicated to Technology

Haney PRC creates package prototypes for all types of products. The company can have prototypes packed-out as sales samples in quantities of one or two, to hundreds, and up to several thousand. Customers can learn about current and advanced packaging technologies; match packaging technologies with the need; and share knowledge and execute ideas.

In order to provide its customers with the most innovative and high quality prototypes and mock-ups, the Haney brothers have invested in an impressive collection of printing technology.

The company has 12 large-format Iris printers from Creo, three Hewlett Packard plotter printers, and an HP Indigo digital web press. Haney also owns an Omega Digicon web press, which supports the Indigo, that features coating, corona treating, and hot foil stamping capabilities. The Omega also features a flexo head, semi-rotary die capabilities for rolls, and slitter capabilities. The company’s in-house prepress operation features the entire DuPont Waterproof system.

To expand its print capabilities even further, Haney PRC is developing a separate company dedicated to the entire discipline of package printing.

"Our vision is to bring in wide web CI flexographic printing equipment, eight to ten colors, 50-plus inches wide; a narrow web flexo press, 12 inches; sheet-fed litho, 28 to 40 inches; full prepress capabilities, which would include digital platemaking for both the litho and the flexo side; and maybe even narrow web gravure," explains Haney.

"We’re trying to have all printing disciplines represented that are true ‘commercial’ presses. Ideally, what we’re looking for is best-in-class technology and current technology. So we’re talking to the major press manufacturers," continues Haney.

Innovation Has its Rewards

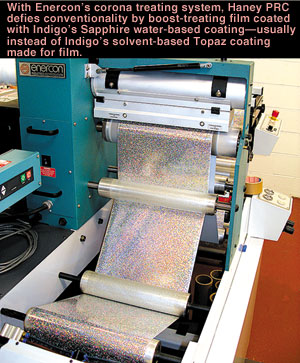

What makes Haney PRC most attractive to its customers is its willingness to try new things, enabling the company to provide them with innovative and unique prototypes. One of the company’s breakthroughs came through its use of Enercon’s corona treating system on the HP Indigo digital web press.

"You have to understand a little bit about how the Indigo and some of the other digital printing technology works," explains Haney. "They all require some sort of coating treatment for the ink to adhere to various substrates. The manufacturers of the ink systems specify a solvent-based coating for plastics. We found by using the Enercon corona treater, we can use HP Indigo’s aqueous-based Sapphire coating on film. That’s something we’ve done [and] found that it works," says Haney.

Haney continues: "HP Indigo’s Topaz coating is specified for films. Sapphire is specified for paper stock. If I buy paper stock in Europe, the acid or pH level is such that I don’t have to apply Sapphire to it. If I buy paper stock in the US, I need to apply Sapphire to it. Sapphire is environmentally friendly, and it absorbs into the paper stock."

Haney contends the company’s understanding of surface treating and its importance to quality digital printing guided them in their experimentation with the Enercon system. "We understand what corona treating is about. We suspected that [Sapphire] may work on film, if boost-treated. It worked better than expected. We had no idea that it would be this consistent. And it’s been one of the major reasons we’ve been able to do what we’re doing, and that’s a fact," Haney maintains. "Sapphire dries immediately and is easy to work with."

In its successful use of Sapphire on film, Haney commends Enercon’s corona treater for allowing the company to push the envelope.

"Enercon is a top-notch company, the kind of company we want to associate with. They are best in class. They think strategically, make good equipment, and invest in technology and R&D."

Haney also believes with this new method of treating film, digital printing finally can find its niche in the converting industry.

"I think people have this misconception of digital printing—that it’s a color copier. But it’s not. It’s printing. It’s ink on substrate, and you’ve got to make it stick. You can’t have picking issues and de-lamination issues," explains Haney. "I think if Enercon can drive that message into the digital printing side of it, it will help the digital printing side grow faster [within the converting industry]."

Forging Ahead

Haney PRC is building its business based on the concept of innovation, quality, and being able, as Haney describes it, to crawl inside their customers’ heads and know exactly what they want.

Haney believes his company’s ability to push innovation through experimentation allows them to deliver on what they say they can provide to their clients.

"We are always pushing our equipment—always. Everything we get, we bring in here, and within a short period of time, we’re making it do something it wasn’t meant to do," says Haney.

"There are not a lot of companies that think the way we do about technology. Most of them want to pull it out of a box and make it run. It’s expensive to try new things, but it’s more expensive in the long term not to."

Etched in History

Haney PRC is headquartered in the landmark Cincinnati Gear building, which was built in 1942. Cincinnati Gear began as a tiny gear factory in 1907 (known then as The Ohio Bevel Gear Co.). Its two Danish owners, John Christensen and Soren J. Sorensen, consolidated with an equally small competitor and continued as The Cincinnati Gear Co. World War II needs caused the company to increase production and build the 50,000-sq-ft building in Mariemont that’s home to Haney PRC today.

The building rests on six acres in an area once called Westover, the industrial section of Mariemont. While fully remodeled and updated, it still houses the general offices, executive offices, a large and richly paneled conference room, and an art deco lobby. John Henri Deekin was the original architect. Says Dan Haney, president of Haney PRC, "Haney PRC is proud to call this grand old building its home and honored to carry on its legacy of strength and craftsmanship."

CONVERTER INFO:

Haney PRC

5657 Wooster Pike

Cincinnati, OH 45227

513/561-1441; haneyprc.com

SUPPLIER INFO:

Enercon Industries Corp. —enerconind.com

Creo Inc. —creo.com

Hewlett-Packard—hp.com

Omega Digicon/AB Graphic Intl. —abgint.com

DuPont Co. — dupont.com