In the Spotlight: Sun Centre Machinery Co.

- Published: October 28, 2019

Leading the Future of Pouch Making Technology

In 2003 the Shanghai Sun Centre Machinery Co. ltd established modern manufacturing facilities in Shanghai, China to produce all machinery related to producing high quality pouches, including innovative pouch machinery, blown film extrusion machines, slitting and laminating machines, and pouch spout insertion machines.

The company was founded in 2015 to sell, engineer, install and service its machinery worldwide. In 2018, Sun Centre USA opened new headquarters in North America along with a new Technology Center in Crystal Lake, Ill. Here, Sun Centre customers could experience pouch making demonstrations, trial run their own pouch configurations, and achieve operator training and certification. At this same location, the company created a machining center for fast turnaround of machine parts for all makes of pouch machinery.

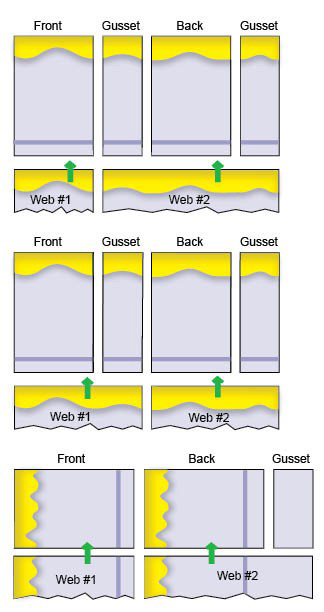

In early 2019 Sun Centre USA enhanced the SCSG 600-850 XL pouch machine as a DR (Dual Registration) model that can now provide front and back registration on all conventional stand-up pouches as well as registered gussets using either one or two films (see film options illustrated in image).

This versatile machine can still produce inserted side gusset pouches, terminated and non-terminated side gusset bags, bag-in-bag formats, and apply zipper and Velcro closures, Applix eazy-lock closures, and dual-lip child-resistant zippers. The XL machine also comes standard with ultrasonic zipper sealing technology.

The dual registration and one-web gusseted pouch capabilities of the XL-DR machine now create significant opportunities for many companies with smaller digital printing presses. Companies with 13, 16 and 20-30 inch wide digital printing equipment can now produce world class pouch packaging with perfect front-to-back registration.

The XL-DR can still run all PE/PE webs up to 57 inches for some of the largest pouch products such as pet food, softener salt, fertilizer and other bulk materials. Customers can also run the smaller 3x3 inch pouches for coffee and snack products. This single pouch machine now produces the vast majority of pouch packaging, from the largest to the smallest. Complete fitment applications, custom die-cutting, and pouch handle options are also readily available.