ETI: Empowerment through Innovation

- Published: February 07, 2023

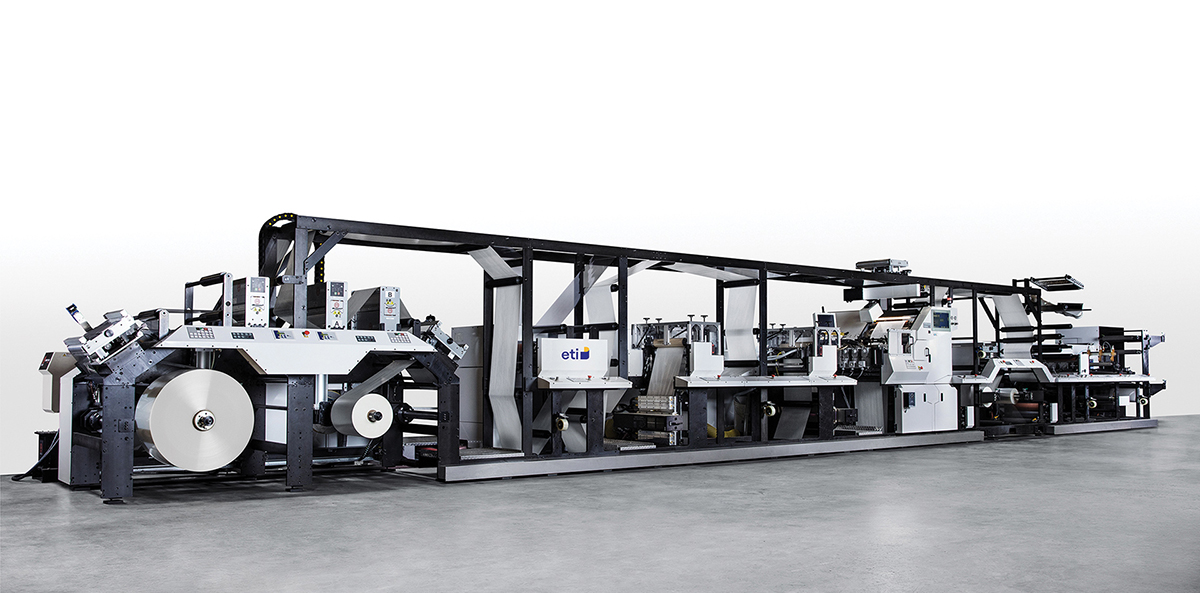

For more than 20 years, ETI has been a trusted partner with players in the narrow-web converting industry. As a pioneer in the art of in-house coating, the company develops and produces specialized equipment for self-adhesive label printing and converting.

How does in-house coating stand out from other technologies? A bit of historical background

Brought about in 2000, the concept of in-house coating has upheaved legacy production methods for label printers and converters. By literally deconstructing and rethinking how a label is fabricated, ETI materialized a novel idea and presented COHESIO—an all-in-one label printing, adhesive/silicone coating, and converting machine. By eliminating the need to outsource label stock procurement, printing businesses suddenly acquired the capacity to truly produce, instead of just printing.

For us, this now well-established, empowering approach stands as the only appropriate way to make a label—From A to Z.

Success factors

In the past two decades, in-house coating technology has established itself as the main alternative to traditional label-making methods. Not only is it a cost-effective solution—reducing adhesive material expenses—but it also boasts sustainability—with its capacity for linerless applications. And we’re not even mentioning the autonomization gained by our clients, which can then freely express their creativity.

From its inception, ETI has been constantly innovating and developing state-of-art know-how unequaled in the industry. Rather than offering one-size-fits-all solutions, its multidisciplinary teams strive to grasp the client’s unique wishes and needs, always taking in consideration the tangible end product. After the conception and configuration phases, our specialists make sure to pass along to the client all the knowledge needed to make educated choices about raw materials and production recipes. This made-to-measure, result-driven approach ensures maximum ROI for the customers and fosters their self-reliance.

Support from our dedicated teams doesn’t stop after the delivery of the equipment. Throughout its lifecycle, our people tag along when the client wants to evolve their system—whether it be a reconfiguration or the addition of a supplemental unit—or when it wants to go after a new niche and requires new production abilities.

New Technology Center

Located on the outskirts of Montreal, Quebec (Canada), our brand new Technology Center offers state-of-the-art equipment, a wealth of resources and an experienced, helpful lab staff. Whether you’re exploring new label possibilities, assessing raw materials, or testing the effectiveness of our equipment, you can conduct your R&D right here on site or from a distance. It’s an exceptional experience that encourages innovation and creativity from start to finish.

ETI Converting Equipment

450-641-7900

This email address is being protected from spambots. You need JavaScript enabled to view it.