Slot Die Coating | The Pressure Is On

- Published: December 02, 2011, By Mark Miller

Slot die coating technology is a function of the coating process, auxiliary system, and fundamental technique. The decision to utilize a coating technology needs to be analyzed against these functions to determine best fit. In the era of clean, thin, and precise converting operations, a customized coating system is necessary to have a technical edge. Building the system from the material up to the process sets the stage for a high precision tool designed around the process needs.

The dramatic increase in the expectations of coated products, in areas as diverse as optical films to battery technology, has put substantial pressure on the systems used to produce the next generation of coated products. It is time for the equipment suppliers to step up as new tools and techniques are required. With increased speeds, thinner coatings, and increased functional performance, awareness of coating techniques and technologies is required. The world is changing and new tools are needed to compete in the changing world markets.

An awareness of coating techniques, technologies, and systems allow for novel adaptations and application to new market opportunities. Slot die technology provides innovative tools that will help coating companies improve precision, tackle new markets, and develop new processes.

INTRODUCTION

Slot die coating was developed as the need for a better and more efficient coating method was required. This process has been successful in replacing other coating methods in applying many types of solutions. A slot coating die is a device that is capable of holding a fluid’s temperature, distributing a fluid uniformly, and defining a coating width. The die is comprised of steel body sections that house the fluid flow chamber.

Slot die coating has four main advantages:

- Increased production speeds | In slot die coating a positive displacement pump is utilized to deliver a constant supply of coating fluid to the slot die. Modification of the coating fluid formula, such as an increase in the concentrate of solids, is allowable in a slot die. This decreases the workload of the drying units, leading to increased production rates.

- Positive coat weight control | The fluid delivery system delivers a constant supply of coating fluid and variations in coat weight are controlled by regulating the pumping rate to line speed ratio.

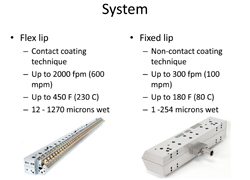

Cross-web distribution control | The slot coating die’s manifold geometry is designed to uniformly distribute the coating fluid, based on the fluid’s rheology. In the case of an adjustable lip die, the lip adjustment system is used to fine tune the cross-web distribution as the fluid exits the slot die. In a fixed lip slot die, the body shim works in combination with the manifold for distribution effects. The slot die support system is just as important as the slot die. The support system accurately and precisely positions the slot die relative to the backup roll or substrate. For elevated temperature applications, dies are designed with multiple heating zones for optimum heat control. Increased heat control promotes uniform fluid viscosity contributing to uniform cross-web distribution.

Cross-web distribution control | The slot coating die’s manifold geometry is designed to uniformly distribute the coating fluid, based on the fluid’s rheology. In the case of an adjustable lip die, the lip adjustment system is used to fine tune the cross-web distribution as the fluid exits the slot die. In a fixed lip slot die, the body shim works in combination with the manifold for distribution effects. The slot die support system is just as important as the slot die. The support system accurately and precisely positions the slot die relative to the backup roll or substrate. For elevated temperature applications, dies are designed with multiple heating zones for optimum heat control. Increased heat control promotes uniform fluid viscosity contributing to uniform cross-web distribution.

- Improved waste management | All of the coating fluid is applied to the substrate via the positive displacement pump and the slot in the die exit (pre-metered coating) . A slot die system is a closed system, which reduces coating fluid contamination. This is especially useful in a clean room environment.

The superior control over coating application, provided by the slot die method, is attributable to its constant application rate. An extruder or positive displacement pump feeds the coating fluid into the die at a pulse-free, uniform rate, and all of the fluid that goes into the die is applied to the web. In roll coating, only a portion of the coating on the applicator roll is actually deposited on the web. The amount varies with such factors as the viscosity of the fluid, the speed of the web, and the speed of the rolls.

The need to re-circulate the remaining coating fluid is a disadvantage of roll coating, attributable to partial use of the coating on the applicator roll. The contamination that can result damages product quality and leads to raw material waste.

Slot die coating systems can transcend limitations of conventional roll coating. Slot die coating emerges as an efficient, controllable alternative to roll coating and other conventional methods of applying fluids to web substrates. For a wide range of adhesives and low-viscosity coatings, today’s market and regulatory forces place a high premium on the advantages of the slot die coating technique. Coating applications in which slot die methods provide new capabilities for meeting these challenges include pressure-sensitive adhesives, transdermal patches, optical coatings, battery slurries, and solar panel coatings.

PROCESS

The conditions most fitting for slot die coating technology when the coating is 0.00004 in. (1 micron wet) up to 0.05 in. (50 mil) in caliper; 1-100,000 cP in viscosity; up to 2,000 fpm in line speed; with temperature control up to 450 deg F. These conditions are not mutually exclusive, as the rheology, surface energy, and flow characteristics of each fluid are unique. A slot coating die can be designed to run an individual fluid or multiple fluids simultaneously. Other useful capabilities of a slot die include intermittent coating capability and lane coating.

SYSTEM

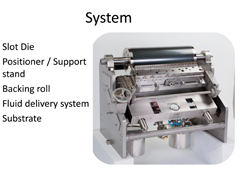

A slot die coating system is comprised of five main components:

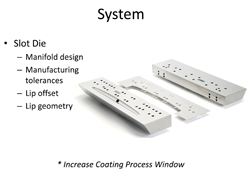

- Die | The slot die pre-meters the fluid onto the substrate. The fluid rheology is the fingerprint of the fluid. It is the comparison of viscosity versus shear rate at a specific temperature. Each fluid has its own rheology, which is used to design the internal flow geometry. The die manifold is the contoured flow geometry machined into the body sections to exacting tolerances. The body sections may be disassembled and split apart for cleaning. The function of a slot coating die is to maintain the fluid at the proper temperature for application, distribute it uniformly to the

desired coating width, and apply it to the web. In a typical construction, the body of one type of slot die coating head is about 9 in. (230 mm) long in the machine direction and 5 in. (127 mm) high; widths up to 118 in. (3 m) are available, as opposed to a typical maximum of 85 in. (2.1 m) for roll coating. The die is split into top and bottom sections that are bolted together. Enclosed within these sections is a flow channel machined into one of the body sections. The key portion of this channel is the coat hanger-shaped manifold, whose widest segment, the exit slot, corresponds to the coating width. The manifold distributes the coating fluid that enters the die to its full target width and is designed to generate a uniform, streamlined flow of material through the exit slot of the die.

desired coating width, and apply it to the web. In a typical construction, the body of one type of slot die coating head is about 9 in. (230 mm) long in the machine direction and 5 in. (127 mm) high; widths up to 118 in. (3 m) are available, as opposed to a typical maximum of 85 in. (2.1 m) for roll coating. The die is split into top and bottom sections that are bolted together. Enclosed within these sections is a flow channel machined into one of the body sections. The key portion of this channel is the coat hanger-shaped manifold, whose widest segment, the exit slot, corresponds to the coating width. The manifold distributes the coating fluid that enters the die to its full target width and is designed to generate a uniform, streamlined flow of material through the exit slot of the die.

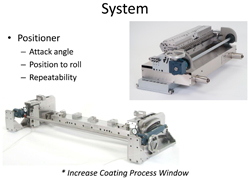

Die Positioner | An adjustable carriage, which precisely positions the slot coating die at the optimum angle and proximity to the roll and isolates the die from vibrations that can affect coating application, is an important support system that should be incorporated. The die positioner is important for stabilizing the interaction between die and moving web utilizing the angle of attack between die and substrate, the distance between the two, and the degree of offset between the lips. These parameters can be adjusted to optimize the process.

Die Positioner | An adjustable carriage, which precisely positions the slot coating die at the optimum angle and proximity to the roll and isolates the die from vibrations that can affect coating application, is an important support system that should be incorporated. The die positioner is important for stabilizing the interaction between die and moving web utilizing the angle of attack between die and substrate, the distance between the two, and the degree of offset between the lips. These parameters can be adjusted to optimize the process.

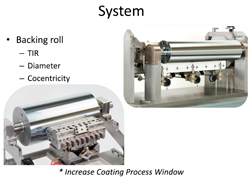

Roll | A backup roll provides the precision surface for most coating techniques. The total indicated runout (TIR) of the roll will provide the basis for the interaction between the substrate, the fluid, and the slot coating die.

Roll | A backup roll provides the precision surface for most coating techniques. The total indicated runout (TIR) of the roll will provide the basis for the interaction between the substrate, the fluid, and the slot coating die.

- Fluid Delivery System | The fluid delivery system has to provide a non-pulsing, constant feed of fluid to the die. This critical piece of equipment works in combination with an accurate line speed control to determine coat weight of the fluid.

- Substrate | This component to the coating uniformity equation is typically outside the control of the machine builder’s influence, but the influence of coating quality and caliper control is just as big.

Each of these components takes on a portion of the tolerance of the coating caliper control. The concern of the system designer is to minimize the influence of each component.

TECHNIQUE

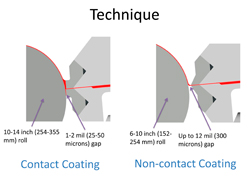

Slot dies are pre-metered heads that uniformly apply coatings to substrates. To provide coatings without defects, dies must be positioned to form an ideal geometry between the substrate and the die lips. This can be accomplished with numerous coating techniques:

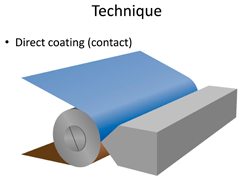

- Wipe/Contact (Direct & Indirect) | Direct coating, in which material is applied directly to a substrate supported by a backup roll, achieves coating thicknesses as low as

0.00075 in. (18 microns) and can replace roll, gravure, Meyer rod, and some knife-over-roll/substrate applications. Indirect coating, in which material is applied to a precision metering roll and transferred to a substrate on a backup roll, can achieve thicknesses down to 0.0005 in. (12 microns) in replacement of the same conventional methods as direct coating.

0.00075 in. (18 microns) and can replace roll, gravure, Meyer rod, and some knife-over-roll/substrate applications. Indirect coating, in which material is applied to a precision metering roll and transferred to a substrate on a backup roll, can achieve thicknesses down to 0.0005 in. (12 microns) in replacement of the same conventional methods as direct coating.

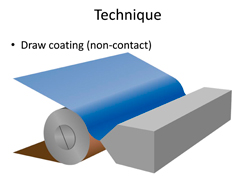

- Draw | Draw coating, in which material is applied directly to a substrate supported by a backup roll from a distance of up to 0.012 in. (12 mil),

achieves coating thicknesses as low as 0.00004 in. (1 micron) in replacement of the same conventional methods as direct coating. This coating technique is typically run at slower line speeds and is a function of the fluid’s elongational viscosity.

achieves coating thicknesses as low as 0.00004 in. (1 micron) in replacement of the same conventional methods as direct coating. This coating technique is typically run at slower line speeds and is a function of the fluid’s elongational viscosity.

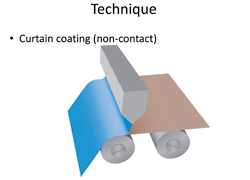

- Curtain | Curtain coating allows for increased production speed.

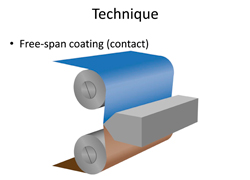

- Free span | Free span coating applies material directly to a substrate

without the assistance of a backup roll. Replacing many knife-over-roll/substrate applications, this method is used with solutions that adhere to the substrate without pressure or, in the case of substrates that absorb material quickly, in cases where penetration of the substrate is undesirable.

without the assistance of a backup roll. Replacing many knife-over-roll/substrate applications, this method is used with solutions that adhere to the substrate without pressure or, in the case of substrates that absorb material quickly, in cases where penetration of the substrate is undesirable.

CONCLUSION

Implicit in this discussion is the importance of precision in the manufacture of slot dies. The smoothness and flatness of surfaces at or near the exit slot of the die are critical for product quality. These surfaces include the lip land just inside the exit slot and the face of the wet lip (the lip passed by the moving web after it has passed the exit slot).

Improvements in dimensional tolerances made possible by precision machining of these surfaces may seem minuscule, but in applications involving high volumes or costly coating materials, the economic gains can be great. The effect of flatness variations becomes progressively greater as coating weights become smaller.

The slot die approach provides many benefits, such as higher line speed capability and greater coat weight uniformity. To realize these benefits, the coating system as a whole must be designed to exacting tolerances based of the rheological characteristics of the fluid. The slot die can then achieve defect-free coatings with increased production speeds, positive coat weight control, controlled cross-web distribution, and improved waste management.

[All images are courtesy of Extrusion Dies Industries LLC]

Roll-to-roll coating industry expert Mark Miller, owner of Coating Tech Service, has 14+ years of slot die coating experience and troubleshooting. Contact him at 612-605-6019; This email address is being protected from spambots. You need JavaScript enabled to view it.; http://www.coatingtechservice.com.