Coating Matters | The 6 C's of Roll-to-Roll Coating Systems

- Published: January 19, 2018, By Mark Miller

Develop a balanced approach to precision coating by understanding these six areas of concentration.

If you'd like to hear from Mark Miller's own lips rather than read his column, titled "Coating Matters | The 6 C's of Roll-to-Roll Coating Systems," click on his podcast below:

{mp3}the-6-Cs-of-roll-to-roll-coating-systems{/mp3}

In all roll-to-roll coating systems, there are what I call the six C's.

In all roll-to-roll coating systems, there are what I call the six C's.

- Continuous

- Compounding

- Coating

- Curing

- Converting

- Control

The six areas of concentration help understand what can form or fail a fluid coated product. Let’s define each a bit further:

1. Continuous – Whether the coated product is a discrete sheet or a continuous roll of material, the fluid dynamics are working within a region of steady-state continuous flow. Also, the substrate is potentially moving in a steady-state continuous manner while the fluid is being applied. The only case where this is different would be where a coating head is moved across a fixed sheet of discrete material, but the functions of movement still apply.

2. Compounding – The fluid to be applied needs to be mixed, masticated, blended, and eventually pumped to the coating head. This is a critical step, because air can become trapped in the fluid and will raise its ugly head when the coating occurs, causing defects that can only be overcome by going back to the source.

3. Coating – After being pumped from the fluid holding tank, the liquid makes its way to the substrate via a coating head. The precision of the coating head equipment, in combination with the other mechanical variables, determines the precision of the coated product.

4. Curing – Energy turns the liquid into a solid. Many forms of energy can be utilized, but heat, light, and electron beam are the most common. The process of curing can improve or disrupt the quality of the precision coated product. This includes the type, the rate, and the amount of energy put into the system.

5. Converting – After the product is coated, the substrate with a cured fluid typically needs to be converted further to provide the end-user with the product in the final shape required for use. This slitting, masking, or ablating step is the final step prior to shipping the product.

6. Control – All of these functions need to have a control scheme to make sure the product can be made over and over again without variation. This requires proper computer programming and mechanical tuning of the tensions, speeds, and pump rates within the system.

Hidden within the compounding operation, there is a seventh “C” that is not included in the process side of this discussion, and that is “Chemistry” and is specific to the industry and application. We will discuss the effect of the rheology on the process, but not product development. Chemistry provides the feedback between the process and product engineer in the development of a new product.

Fluid coating is fundamental chemical engineering process utilized across many industries including adhesive tapes and labels, pharmaceutical drug patches, optical film, and battery technology. The microstructures internal to the coatings and the morphology external to the coatings develop the functions required (optical, mechanical, photochemical, etc.). The 6 C's provide the variable controls to make the proper microstructures and morphology required for functional utilization of the final product.

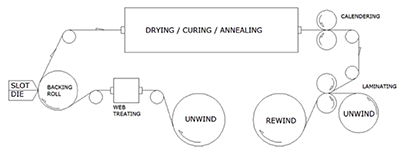

Let’s look at these unit operations a little bit closer. When the liquid is pumped to the coating head and is placed on the substrate, an air barrier exists between the coating head and the substrate. Coating is replacing the air at the substrate surface with a liquid. This process is continuous for the duration of the required coating (full roll or discrete panel). Prior to exiting the coating head, the liquid is compounded (mixed) and pumped to the coating head (slot die) where it makes the transformation from a liquid in a pipe to a fluid displacing the air on a substrate.

The operation of coating is continuous, even if you are coating a discrete glass panel. With both roll-to-roll coating and discrete panel coating, there is a start and stop. The goal is to get to a steady state position for fluid flow and coating quickly.

For slot die coating, the thickness of the wet layer can be coated 1-500+ microns wet to be further cured into place at the same or thinner dry coating thickness. This points to the critical connection between coating and curing (solidification). How the fluid travels through the tank, pump, pipe, coating head, and eventually exiting onto the substrate helps define the internal microstructure while the pump rate, line speed, surface tension, and energy and curing process help define the external morphology. Remember, we are balancing a liquid on a solid in a careful balance until cured into place.

Coatings below 1 micron wet thickness are typically applied through deposition techniques. I think of fluid coating as coating wet and drying down to a thickness and deposition as building up solid layers to obtain a submicron coating. Thin film coating (less than 1 micron as initial applied) is completed through vapor deposition or sputtering.

Most of the time, liquid coating is presented as one fluid and one substrate, but there are many variations. Ever since photographic film was developed as a functional coated product, coating multiple fluids at once has been attractive. The interaction of the fluids and barrier layers can confound the complexity of simply displacing the air at the substrate interface. When coated together, the multiple fluids require barrier layers of fluids to deter mixing. Another option is to coat one fluid, cure, then coat the next fluid and cure again. This method of multiple passes requires more production time and more handling, but simplifies the coating head operation.

In the development of a new product, the fluid formulation, process conditions, required microstructure, and final product performance all need to be considered. This fluid will either be cured as the final structure, peeled off the substrate, or have a second substrate laminated to it prior to converting. Substrates can also have a porous nature allowing for impregnation of the fluid into the substrate, or a rigid nature, such as glass.

The key to successful coating is to deliver the fluid in a precise manner (cross-web) consistently (down-web). Coating heads control cross-web variation while pump rate and line speed control down-web variation. Understanding details associated with all six C’s help you develop a balanced approach to precision coating.

Mark D. Miller, author of PFFC's Coating Matters column, is a fluid coating expert with experience and knowledge in the converting industry accumulated since 1996. Mark holds a Bachelor's degree in Chemical Engineering from the Univ. of Wisconsin-Madison and a Master's degree in Polymer Science & Engineering from Lehigh Univ. and a Juris Doctor from Hamline Univ. Mark is a technical consultant and CEO of Coating Tech Service LLC. He has worked in web coating technologies and chemical manufacturing operations and is a certified Six Sigma Black Belt trained in both DMAIC and DFSS disciplines. Coating Tech Service provides process troubleshooting and project management for precision coated products. Mark has extensive process knowledge in high precision coating applications including thin film photo voltaic, Li-Ion battery, and optical systems technology. Mark has been integral to new developments and technology that minimize product waste and improve process scalability.

Mark D. Miller, author of PFFC's Coating Matters column, is a fluid coating expert with experience and knowledge in the converting industry accumulated since 1996. Mark holds a Bachelor's degree in Chemical Engineering from the Univ. of Wisconsin-Madison and a Master's degree in Polymer Science & Engineering from Lehigh Univ. and a Juris Doctor from Hamline Univ. Mark is a technical consultant and CEO of Coating Tech Service LLC. He has worked in web coating technologies and chemical manufacturing operations and is a certified Six Sigma Black Belt trained in both DMAIC and DFSS disciplines. Coating Tech Service provides process troubleshooting and project management for precision coated products. Mark has extensive process knowledge in high precision coating applications including thin film photo voltaic, Li-Ion battery, and optical systems technology. Mark has been integral to new developments and technology that minimize product waste and improve process scalability.