Cortec® Launches EcoSonic® Bubble Film and Bags that Combine Cushioning Packaging with Permanent ESD protection and VpCI® Corrosion Protection Technology

- Published: October 10, 2024

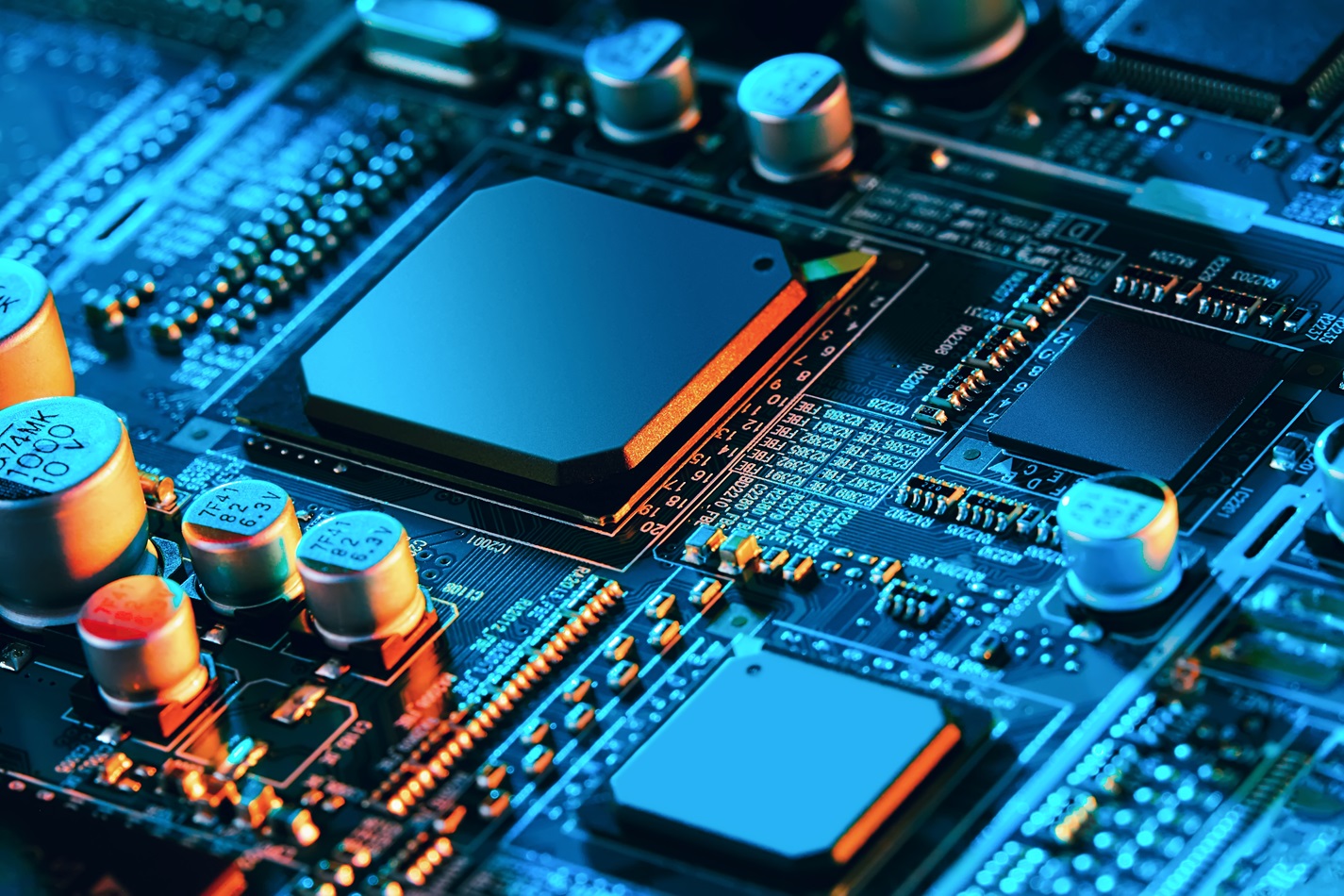

ESD managers in the electronics industry are well-aware of the critical threat electrostatic discharge poses to electronic equipment. Did you know that you can shield your components from both ESD and corrosion at the same time? Cortec® Corporation’s European plant, EcoCortec®, launched EcoSonic® VpCI®-125 HP Permanent ESD Bubble Film and Bags powered by Nano VpCI®. They combine vapor phase corrosion inhibitors with cushioning packaging bubble bags and permanent ESD protection to protect sensitive electronic equipment from corrosion, physical damage, and the creation of triboelectric charges. This innovative packaging solution provides comprehensive protection for electronics throughout the manufacturing, shipping, and storage processes.

EcoSonic® VpCI-125 HP Permanent ESD Bubble Film and Bags work by saturating the enclosed airspace with Vapor phase Corrosion Inhibitors that form a protective molecular layer on all packaged metals without leaving behind a noticeable film or residue. The bubbles serve as cushioning, dunnage, and void fill material. Why combine corrosion and permanent ESD protection in a single bubble bag? Consider this: electronics are complex and sensitive components that often contain multiple metal types within a single unit. Any discoloration, let alone corrosion, can lead to rejection by end users due to the potential for failure.

While dry environments pose small risk, shipping electronics across continents or exporting them worldwide exposes them to unpredictable and extreme conditions—fluctuating temperatures, humidity, and even condensation. This creates a fertile ground for corrosion within the electronics package. And let's not forget the high costs and logistical challenges of climate-controlled warehousing in hot, humid climates. By combining corrosion protection with ESD packaging and bubble wrap, you're combating three threats at once. It's a more convenient and efficient solution that ensures your valuable electronics arrive at their destination safe and undamaged.

Where to Use EcoSonic® VpCI-125 HP Permanent ESD Bubble Film and Bags

EcoSonic® VpCI®-125 HP Permanent ESD Bubble Film and Bags are recommended for packaging integrated circuits, printed circuit boards, PCB components, telecommunications equipment, electronic and electrical panels and enclosures. Fragile or static-sensitive components where triboelectric charge generation and corrosion are concerns will receive full protection.

EcoSonic® VpCI®-125 HP Permanent ESD Bubble Film and Bags meet NACE TM0208-2018 “Vapor Corrosion Inhibiting Ability” standard for corrosion protection as well as German TL-8135-002 standard for corrosion protection. They are available for delivery to customers worldwide from EcoCortec® plant located in Croatia. Film and bags are available in custom-size rolls, sheeting, or heat-sealed bags.

For more information, visit http://www.cortecvci.com.