Sun Chemical White Paper: Color Management

- Published: March 28, 2025

Ensuring Color Consistency in Every Corner of the Globe

With access to hundreds of color specialists, more than 20 regional color centers and an unrivaled local support network, Sun Chemical’s global SunColorBox tools make it easier to achieve color accuracy.

The colors on packaging are printed on many different substrates using a range of processes. Whether it is a laminated pouch, folding carton milk container or various labels on a plastic tumbler for food packaging or plastic spray bottles, tubes or containers for household goods, each substrate responds differently to various inks, processes and lighting.

Introduction

A critical component of brand strategy, color is essential to brand recognition. At one level it helps consumers find their favorite products on the supermarket’s crowded shelves; at another, it is an intrinsic part of the brand’s “personality,” telling us what the brand stands for and what we can expect from it.

The importance of color in marketing has been confirmed by consumer research on a number of occasions. For example, according to the Institute for Color Research, people make a subconscious judgment about a person, environment or product within 90 seconds of initial viewing, and between 62% and 90% of that assessment is based on color alone.

Similarly, a survey conducted by Xerox Corporation and International Communications Research1 produced the following results:

- 92% believe color presents an image of impressive quality.

- 90% feel color can assist in attracting new customers.

- 90% believe customers remember presentations and documents better when color is

- 83% believe color makes them appear more successful.

- 81% think color gives them a competitive edge.

- 76% believe that the use of color makes their business appear larger to clients.

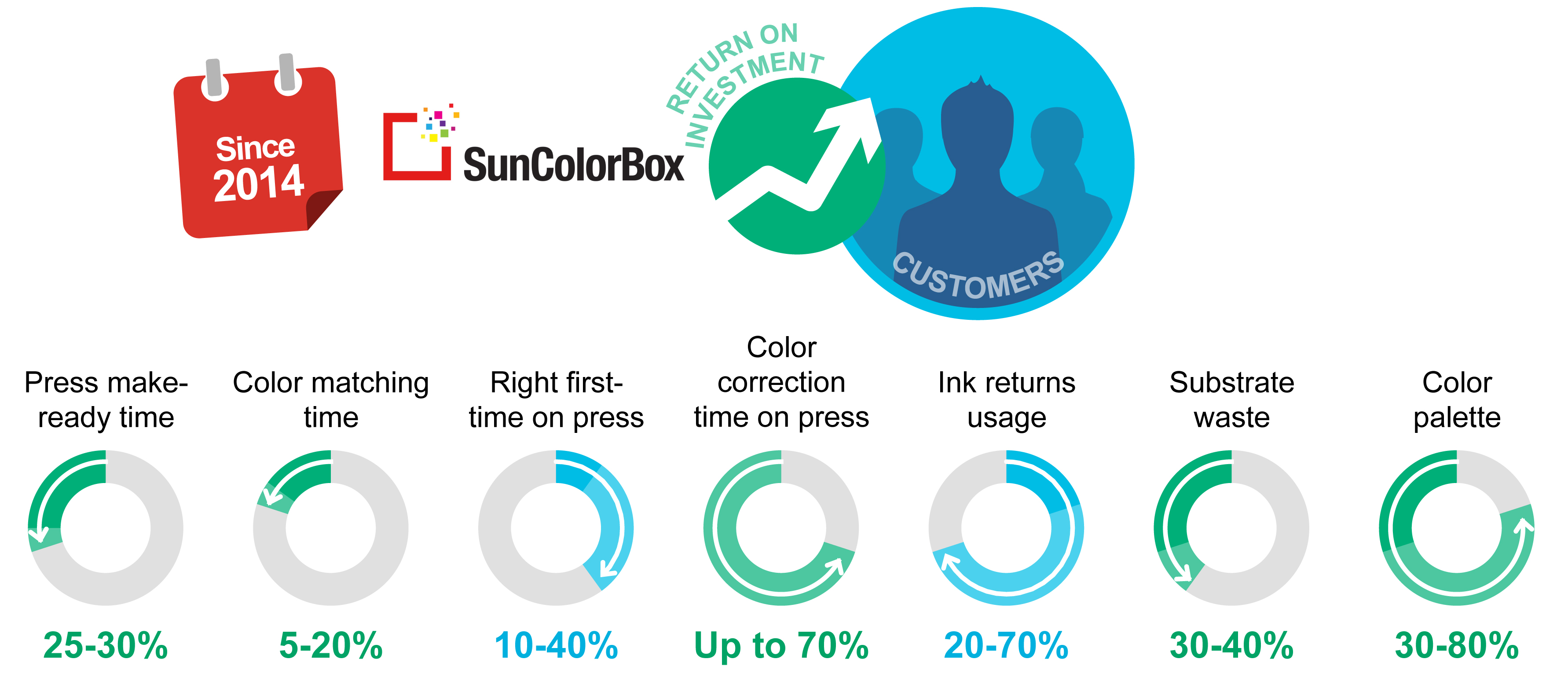

Since 2014, customers who have implemented some portion of the SunColorBox solution have achieved substantial savings.

These results are also supported by research by the secretariat of the Seoul International Color Expo2, which found that:

- 6% put most importance on visual factors when purchasing products.

- 7% think that color accounts for more than half among the various factors important for choosing products to purchase.

As color plays such a critical role, it is essential that consumers see the same color on every version of the product, however it is packaged and wherever it is sold. Failure to control color consistently or to use too little or too much color can reduce brand impact, confuse customers and damage sales. But this is only one of the many challenges faced by brand managers and the converters and printers they work with. Other challenges include:

- Many substrates, multiple channels—The colors on pouches, bottles and boxes are printed on many different substrates using a range of processes. Each substrate responds differently to different inks, processes and lighting. Ensuring consistent color under all these conditions is a complex affair.

- More variety, shorter runs—When U.K. supermarket ASDA (owned by U.S. retailer Walmart) decided to redesign its pet food ranges, they had to work across five packaging formats, including cartons, labels, bags and flow wraps and 345 SKUs. And before its competitor, Tesco, took action to reduce the number of products it sold, the supermarket had over 90,000 SKUs on its shelves.

- Multiple product variants—Today brand owners have to manage more and more product versions—a direct result of the way digital technology tells you more about customers’ buying habits. The more you know, the more you can customize products to precisely target audiences and markets.

- Agile, flexible supply chains—Identifying new trends is just the beginning; brand owners have to respond to changes quickly, as well as to new initiatives from competitors. Supply chains must be agile and flexible, optimized to get new products on the shelves as quickly as possible—even when brand owners, designers and converters are spread around the globe.

- Constant change—If brands are always changing, spinning off new variations on a theme, then so is the environment they work in. Tighter regulation—reducing artificial colors and preservatives, for example— may mean new substrates or pigments. Switching a printing process, from offset to gravure, or flexo to digital, changes the game. New materials and technologies pose fresh new challenges.

- Color perception—Color plays an important part in conveying information, but remember that there are an estimated 200 million people worldwide who suffer from deficient color vision in one form or another. Some are simply color blind; others have age-related conditions such as glaucoma or cataracts. Packaging design needs to take account of this.

Sun Chemical’s team at the Aliaga, Turkey, Color Innovation Center.

From these challenges, it’s clear that brand owners are under constant pressure to streamline processes, introduce efficiencies, manage cost by eliminating waste and accelerate time to market.

But the bedrock of brand identity is color; if that isn’t right, the integrity of the entire supply chain is compromised. So it follows that achieving consistent color across substrates, print processes and national frontiers is essential to the efficiency of the whole packaging workflow.

There are two major obstacles to this. The first is the number of variables that make true color consistency elusive—all those package types, substrates, inks and so on. The second is the number of parties with input to the production and approval of color. The universe of brand owners, designers and converters is vast and geographically spread—producing the 345 ASDA pet food SKUs mentioned earlier involved 20 printers.

While software and hardware tools for color management are available, they are often deployed inconsistently by the individual links in the supply chain. The result is a chain of disconnected islands of solutions, rather than a community working to an industry-standard reference, with every supplier looking at providing its own solution that works within its own environment, without the necessary integration needed for a highly efficient workflow. In practice, “color management” is often a mix of gut feel, operator experience and the inconsistent use of measurement tools and samples.

Try to map the color management process in many packaging supply chains and the picture can be chaotic, with communication between the different parties often going around in loops of approval and re-approval. For brand owners, this is a recipe for error, inefficiency and unnecessary cost. It’s no surprise that color that fails to meet brand owner expectations is the primary reason for rejects and reworks.

Overview of SunColorBox

Sun Chemical is committed to innovation in inks, pigments and coatings and to working in partnership with leading color measurement, printing and converting technology developers. As a result, we have unrivaled experience working with companies in every link of the packaging supply chain, guiding brand owners from concept to converter to consumer, through a full range of solutions.

Focusing that experience on the issues of color management, Sun Chemical developed the SunColorBox, a unique set of tools and services that enables consistent and accurate digital color communication throughout the entire packaging supply chain.

Since 2014, Sun Chemical has been implementing the SunColorBox solution at a large number of customer sites around the world using all printing technologies, including flexo, gravure and offset, and has achieved the following substantial savings for customers:

- 25%–30% savings in press make-ready time

- 10%–40% savings from right first time on press

- 20%–70% increase in ink returns usage

- 30%–40% reduction in substrate waste

- 30%–80% color palette reduction

Sun Chemical’s patented technology3 enables the communication of a consistent, digital description of the desired appearance of a product. Sun Chemical has licensed the technology to X-Rite to enable PantoneLIVE, the end-to-end color communication ecosystem that bridges the gap in digital color communication between brands/designers and their print, packaging or manufacturing supply chains.

A menu of added-value services, the SunColorBox offers every customer— whether printing spot color, CMYK or extended color gamut—a tool to manage colors and ensure their consistency. It allows each customer to select the most suitable services based on the size of their business and the investment required.

The tools in SunColorBox comprise:

- SunConsulting—A custom site assessment and color audit.

- SunDigiProof—An on-site, on-demand, color-accurate inkjet swatch for flexible packaging.

- SunDigiGuide—A custom, digitally printed book of an individual customer’s production colors.

- SunMatch—A color-matching and -validating software platform.

- SunColorQC—A color quality control software platform.

- Hardware & Software—A procurement service.

- myColorCloud by Sun Chemical—A cloud-based repository, using PantoneLIVE infrastructure, for customers’ spot color libraries.

- PantoneLIVETM—A cloud-based architecture that enables digital specification and communication of Pantone standards to all stakeholders in the global supply chain.

- SunCMYK—A service to help printers and converters achieve the ISO 12647 standard for process colors.

- SunECG—A solution to address the growing demand from customers for expanded color gamut (ECG) printing by adding colors to the standard CMYK set.

Support

For a printer or converter who may have handled their color management in a certain way for the past 20 years or more, it is not always easy to accept the level of change required to implement a digital color management project. That is why at Sun Chemical we have developed our centrally managed but locally supported model, the quality and standard of which we feel really set Sun Chemical apart in the market.

We believe that there is no better person to implement a digital color management project for a customer than the person who has built a relationship with that customer, knows the challenges they face and can speak the local language. So, while our central color management team manages digital color management projects globally, the implementation and support are all provided by the local Sun Chemical technical support personnel.

Globally we now have more than 300 highly trained personnel, our SunColorBox specialists, with supporting links to our Color Centers, where PowerUsers have been trained in our digital color management procedures. We have more than 200 customers globally using tools from the SunColorBox.

In addition, we have created Color Innovation Centers in Sun Chemical Yate (UK), Charlotte (USA), Aliaga (Turkey) and Mexico City (Mexico). As we have a full digital color management workflow in place at each of these locations, we can run in-depth customer workshops and training events at which customers can gain hands-on experience with all the varied software and hardware in the workflow to understand how this can be applied to their business.

The ongoing support and training required to implement a digital color management project can be substantial, but we know the difference it can make to customers, so Sun Chemical approaches each project as a joint venture—we provide whatever level of support is required to reassure customers that they have made the right decision and to ensure that the project is completed successfully.

Unlock the power of color with Sun Chemical’s SunColorBox suite of solutions.

1 Conducted by Xerox Corporation and International Communications Research from February 19, 2003 to March 7, 2003, margin of error of +/- 3.1%.

2 Secretariat of the Seoul International Color Expo 2004.

3 U.S. patent nos. 7,034,960; 7,202,976; 7,268,918; 7,417,764; 7,738,149 and their foreign equivalents.