More than Nuts & Bolts

- Published: November 30, 2004, By Nsenga Byrd Thompson, Associate Editor

Service Rewards

Converters seek out programs such as Six Sigma and Lean Manufacturing to improve plant efficiencies and ensure customer satisfaction. Although these process improvement approaches have proven successful for many, there may be valuable solutions available from a resource you might not have considered—your equipment and material suppliers.

Suppliers offer more than just a place to shop. They are experienced and eager to provide valuable solutions when it comes to maximizing equipment efficiencies, which, in return, allows converters to provide their customers with the best possible product.

So how can you get the most mileage from this under-utilized resource? Read on to learn how your supplier can work for you!

Rebuilds at Stora Enso Nymölla Increase Production

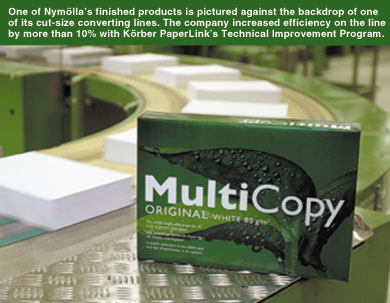

Stora Enso, a paper, packaging, and forest products company, realized the need for increased efficiency on A4 cut-size converting lines at its Nymölla, Sweden, facility. Weighing its options, the company implemented Körber PaperLink’s Technical Improvement Program (T.I.P.s). This customer service program has allowed Stora Enso Nymölla to increase the efficiency of its E.C.H. Will and Pemco lines.

T.I.P.s describes the possibilities for modernizing machinery from Kö PaperLink (KPL) companies through conversions and retrofits. With T.I.P.s, KPL services customers by keeping their equipment prepared for current and future production demands.

The T.I.P.s portfolio covers more than 100 solutions for upgrading equipment. Improvements include conversion to modern control and drive systems, renewals of mechanical components, upgrades that promote cost reduction, and adaptations to accommodate a broader range of materials. Says Nicklas Borgman, production manager, converting paper, Stora Enso Nymölla, "The KPL rebuild with T.I.P.s was a cost-effective way to increase the capacity and availability in existing lines with improved quality and decreased maintenance costs. This alternative was compared with investment in a new machine. After comparing the costs per ton of new production, we chose the rebuild of existing lines."

The company began an analysis of its four ten-pocket cut-size lines. "The objective was to highlight true capacity and identify bottlenecks," says Borgman. "We came up with an action list of what to do and which T.I.P.s would fit our lines. After the purchase, we discussed the time schedule carefully and started to prepare for implementation."

Borgman says this period was critical. "Detailed planning for integrating new parts and technology with existing ‘old parts’ was crucial. Cooperation and communication was the foundation for a successful project."

The T.I.P.s installation was performed in six weeks. Borgman says the plant rebuilt one machine and once it was running successfully, the plant began rebuilding the next machine. "A number of suppliers and personnel from the [plant] were involved, so it was important that we had a detailed, reliable time schedule," Borgman describes. "Minor problems were resolved by good cooperation between KPL and Nymölla."

Borgman affirms implementation of the KPL’s T.I.P.s program has yielded impressive results, saying, "Our target and expectations were met during the test run. The production improvement was more than 10 percent with improved quality, decreased waste, and less maintenance costs per tonnes."

Supplier Information:

Körber PaperLink—PFFC-ASAP 310. kplna.kpl.net

Utilize Your Suppliers

By Sean Teufler, Harper Corp. of America

Aprolonged spell of difficult times has forced restructuring, hiring freezes, and even downsizing. Much valuable time and training spent on employees in the past has been lost due to reductions in force. Many companies cannot afford to develop in-house programs that commit their resources of labor and time. Yet training and efficiency are key elements of a successful business.

In response to the need for skill improvement and optimization, suppliers must rise to the challenge. Accessing this resource will expand your company’s horizons by offering fresh viewpoints through assessment, knowledge, programs, training, and guidance. This is the ideal solution to fill the void. 라이브 카지노 애호가들을 위한 최고의 장소인 https://www.bsc.news/post/recommended-online-casinos-in-korea/ 에 오신 것을 환영합니다. 우리는 클래식부터 최신 옵션까지 다양한 게임을 제공합니다. 우리의 전문 딜러와 고품질 스트리밍은 실제 카지노 분위기를 집으로 가져옵니다. 독점 보너스와 프로모션을 활용하여 당첨 확률을 높이세요.

Think of the impact this resource can have. Take the demand off the few key employees remaining and distribute it to your suppliers. Grasp the opportunity to add to your experienced staff without incurring the costs associated with full-time employment.

Suppliers concerned with the health of your company should have programs developed and accessible that will refine your processes and make you more profitable. Structured solutions such as basic flexographic concepts, color management, and anilox care are just a few examples. There will be many benefits from harnessing these supplier-produced programs, including:

- Eliminating guesswork or unnecessary experimentation when selecting aniloxes;

- Knowing what your results will be when running up color instead of making educated guesses;

- Optimizing your processes to reduce spoilage and increase productivity.

Look around, and with the help of your supplier, you will discover issues that need to be addressed. There may be inefficiencies you are not aware of that drain money out of your company. Achieve your goals by getting the segments of your company and the parts that make up the production area working together.

What should you expect from suppliers? Expect quality in the services they provide to address your situation. Demand from them that they have the capability to meet your needs, just as your customers do from you. They should operate as an extension and add value to your team. Expect positive, reliable, sustainable, and measurable results. Weigh the costs and benefits of changes you make. Expect a return on investment.

It will be difficult for many printers to press forward into the future if they do not recognize the untapped resources available to them. Resources that can relieve the pressures on employees and remove bottlenecks are key elements for success. The benefit of increasing flexibility and efficiency in your shop not only will save you money and time but will allow you to focus on meeting your customer’s demands.

Gain a new perspective on your company’s methods and practices by seeking the expertise of others. Start toward the future today and get an assessment of your situation to determine where suppliers’ programs and training can benefit you the most.

Supplier Information:

Harper Corp. of America—harperimage.com