Hilex Poly Benefits From ShurTape Sealing System

- Published: December 11, 2014

HICKORY, NC | Hilex Poly Co., Hartsville, SC, is a manufacturer and recycler of plastic bags and film products. At the company’s facility in Milesburg, PA, more than 18.5 million bags are produced daily for use at large national chains, “mom and pop” shops, and more.

HICKORY, NC | Hilex Poly Co., Hartsville, SC, is a manufacturer and recycler of plastic bags and film products. At the company’s facility in Milesburg, PA, more than 18.5 million bags are produced daily for use at large national chains, “mom and pop” shops, and more.

Hilex Poly maintenance planner Craig Confer is responsible for maintaining the packaging equipment that seals an average of 15,000 cartons of bags per day. With a 24-year track record of supplying good quality bags to customers in a timely manner, properly functioning equipment is critical to ensuring cartons are securely sealed and ready for shipment nationwide.

“Reliability of all equipment in our facility is a must as we run a lean team and can’t afford to stop daily activities to perform maintenance due to unscheduled failures,” said Confer.

However, Hilex Poly was frequently experiencing quality issues with the tape applicators running on its automatic packaging equipment. “They weren’t reliable. Parts were wearing out, they weren’t cutting the tape right, or the tape would recoil into the rollers,” he suggested.

Time For a Change

So, Confer contacted Sandusky, OH-based Breckenridge Paper & Packaging to discuss his sealing needs. He was searching for a high quality tape applicator that would require little maintenance, especially as his existing tape applicators required continuous attention to keep them running. He also expected both the tape applicator—and packaging tape—to deliver a better, more secure seal.

So, Confer contacted Sandusky, OH-based Breckenridge Paper & Packaging to discuss his sealing needs. He was searching for a high quality tape applicator that would require little maintenance, especially as his existing tape applicators required continuous attention to keep them running. He also expected both the tape applicator—and packaging tape—to deliver a better, more secure seal.

He admits he didn’t know much about Shurtape until he started his search, but agreed to test The ShurSEAL Solution, a carton sealing system that combines Shurtape HP Series packaging tape with a PrimeLoc tape applicator to produce consistent and secure seals, carton after carton.

“We installed the first tape applicator on a bag machine and everyone liked it. So, we pursued additional tape applicators for seven other machines,” said Confer.

The facility has two styles of automatic packing machines—one that allowed the new tape applicator to be dropped in; the other required slight adjustments to the spacers. But, Confer suggests the install was quick and simple, taking only about 15 minutes to complete.

With a history of manufacturing and maintenance personnel having to inspect the old tape applicators on a daily basis, Confer was particularly happy with the fact that his packers wouldn’t have to perform any maintenance on the new sealing system. “The tape applicators are good quality and maintenance-free. I don’t have packers sticking a finger in to make adjustments.” And, if he does experience issues, he can rely on technical support to fix the issue or replace the tape applicator if needed.

Sturdiness and durability of the PrimeLoc tape applicators are another advantage of The ShurSEAL Solution, according to Confer. “The old tape applicators were made from a sheet metal frame and were very flexible. The PrimeLoc tape applicators are solid. You can’t push them and make them bend,” said Confer.

A Better Bond

In addition to reliability and maintenance issues, Confer suggests they were having problems sealing cartons securely.

In addition to reliability and maintenance issues, Confer suggests they were having problems sealing cartons securely.

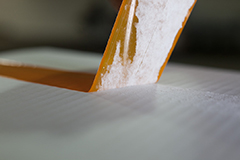

The existing tape applicators weren’t sufficiently wiping down the tape on the carton, which resulted in loose seals. Without the proper tape adhesion, the tape wasn’t able to make a full—or secure—bond, making it easy to separate the tape from the carton simply by pushing the seal.

With The ShurSEAL Solution, Confer has the advantage of unmatched wipe-down force, offered by multiple flexible wipe-down points on the PrimeLoc tape applicators. This allows for full utilization of the tape’s adhesive, so there’s a better, more secure seal on cartons—even those that are under-filled.

Those wipe-down points, combined with Shurtape’s HP Series packaging tape, which offers the highest holding power to fiberboard in the industry, yield a reliable, tamper-evident seal and provide increased fiber tear to offer visual evidence the tape has been removed or tampered with.

Simply put: “now you can push down on the carton and the tape won’t move,” suggested Confer.

Waste Not

Waste has also been reduced with the HP Series packaging tape. Before making the switch, Confer suggests his packaging tape would break randomly throughout the roll. “The old tape would get thrown away because it wasn’t cutting right. It would just break randomly throughout the roll,” said Confer. “The HP Series tape is bar-none.”

Waste has also been reduced with the HP Series packaging tape. Before making the switch, Confer suggests his packaging tape would break randomly throughout the roll. “The old tape would get thrown away because it wasn’t cutting right. It would just break randomly throughout the roll,” said Confer. “The HP Series tape is bar-none.”

Designed with a unique hot melt adhesive formula to deliver an instant, strong bond with cartons to keep them secured, HP Series provides Hilex Poly with a reliable seal from the packaging line to the customer.

The tape is designed for versatility and performance. In addition to running machine-length rolls in the automatic packing equipment, packers at Hilex Poly use manual tape guns, too. “We take smaller rolls and use them in hand-held tape guns. Now, there’s no waste—we’re using the tape right down to the core,” said Confer.

The eight machines fitted with The ShurSEAL Solution are “running flawlessly.” Confer hopes to outfit the rest of his machines in the near future. “We’ve had no issues and people really like them,” said Confer. “I am 100 percent pleased with them.” And, happy with the service they received from Breckenridge, Hilex Poly has moved all packaging needs—including tape, stretch and more—to the distributor.