Davis-Standard to Display Direct Drive Technology

- Published: February 06, 2015

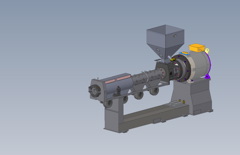

PAWCATUCK, CT | Davis-Standard will feature a 3 1/2 (90 mm) direct drive extruder at NPE2015, The International Plastics Showcase, March 23–27, in Orlando, FL.

Company says a recent series of tests conducted at its Technical Center has shown direct drive technology to have significant advantages in energy consumption, sound level, and output consistency over AC and DC extruder models.

“We continue to discover ways to manufacture equipment that is environmentally sustainable and supports the profitability of our customers,” says John Christiano, Davis-Standard’s VP of technology. “Our experiment with the direct drive technology is an example of that innovation. Our side-by-side comparison of direct drive versus AC and DC drive technology revealed consistently quieter operation that reduced noise by as much as 70 percent. Screw design optimization in combination with these extruder design enhancements can lead to up to a 15 percent further improvement in energy efficiency.

Christiano believes there are several factors that contribute to the improved performance of the direct drive extruder model. The direct drive operates on a permanent magnet synchronous motor, which does not require a mechanical gear reducer to multiply torque to rotate the screw. This, coupled with an energy-efficient screw design, enables the extruder to process a greater variety of resins with consistent quality and outputs. In addition, he says an innovative heating/cooling system, narrow footprint, and low-maintenance design further result in operating cost reductions and energy efficiency.

The direct drive technology is available for processes in several application areas in sizes to 4 ½ inches (114 mm) and it can be customized as needed.

This email address is being protected from spambots. You need JavaScript enabled to view it.