Beta Industries Offers Crease & Fold Analyzer

- Published: May 18, 2015

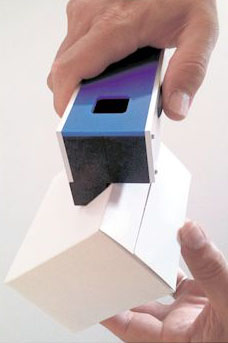

CARLSTADT, NJ | Beta Industries has introduced the Betafold Crease & Fold Analyzer, a handheld, portable quality control tool for real time production and setup correction to minimize uncontrolled variations in the process that can cause expensive, unusable product rejects.

CARLSTADT, NJ | Beta Industries has introduced the Betafold Crease & Fold Analyzer, a handheld, portable quality control tool for real time production and setup correction to minimize uncontrolled variations in the process that can cause expensive, unusable product rejects.

For the desired production result, folding cartons’ multilayer construction adds bending stiffness to the product, producing high quality folds with good appearance and structural integrity while the bending stiffness has to be reduced by the creasing matrix. The localized weakening of the board, in a well-defined, controlled pattern, acts as a hinge during the subsequent box forming process.

The BetaFold Crease & Fold Analyzer measures and documents the dimensions, angles, and symmetry of the crease and bead for proper setup and process control in the production run, as well as to verify the dye and setup at the start of the run.

Available to the user is the all important detail information for package design, material, and process evaluation, as well as machine make-ready. In high-volume production environments the production operator needs only one click for each critical analysis as well as to automatically capture the information to a database. Statistics are automatically calculated while reports are generated for documentation and process control.

The BetaFold Crease & Fold Analyzer’s user-friendly software and hardware capture and analyze images of the crease and automatically display, analyze, and record the data for real time production corrections, documentation, and report generation.