New Era Converting Machinery Develops Flexible Glass

- Published: July 27, 2015

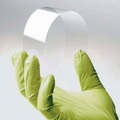

PATERSON, NJ | New Era Converting Machinery announces a complete, clean-room ready turnkey system for conveying and processing flexible glass substrates.

This began when a glass manufacturer approached New Era with its ideas and challenges, and New Era came back to them with the beginnings of what would become an unwinding and conveyance system said to allow a wide variety of downstream processing for the flexible glass. Company says that after some collaborative fine tuning between the two companies, the final design was engineered to operate with the high degree of precision and repeatability that the client required.

“This project presented numerous challenges from a web handling perspective,” says Paul Lembo, VP at New Era. “The ability to unwind and convey the flexible glass substrates with as little tension as possible, while still maintaining control of the substrate for downstream processing was paramount.

Reportedly, the uses for flexible glass in markets such as portable electronics and building products are already well documented, but the potential uses for these products are growing every day. The benefits of flexible glass are said to include optical transmission, surface roughness, thermal stability, and moisture/gas barrier properties, all of which are well suited for electronics, both in the manufacturing process and for the devices end use

Flexible glass can be used in a variety of display types for portable electronics. Whether the display is flat, curved, or designed to flex and take on different shapes, the properties described above make glass a natural fit for these products, says company. The potential to fold up a tablet or unroll the screen of a phone opens new doors for the portability of devices.

“Our goal has been to create equipment which will enable our clients to add value to flexible glass substrates in much the same way someone would coat or laminate film products,” says Lembo. “This means we could offer continuous web processing of flexible glass in addition to conventional roll-to-sheet type operations. We expect this industry to grow exponentially and are proud to be working with some of the leaders in this technology.”

This email address is being protected from spambots. You need JavaScript enabled to view it.