PhilCorr Reports Significant Reduction in Energy Costs

- Published: January 06, 2016

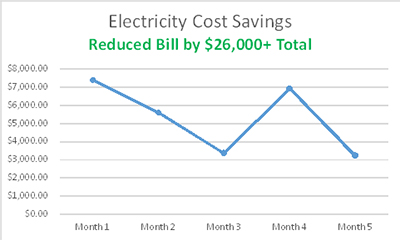

LONG LAKE, WI | PhilCorr, a 120,000 sq-ft corrugated sheet-feeder plant based in Vineland, NJ, recently reported a $26,000 reduction in electricity costs accrued over a five-month period. The substantial savings are a direct result of its custom WPS Global Inc. system installation in March 2015.

LONG LAKE, WI | PhilCorr, a 120,000 sq-ft corrugated sheet-feeder plant based in Vineland, NJ, recently reported a $26,000 reduction in electricity costs accrued over a five-month period. The substantial savings are a direct result of its custom WPS Global Inc. system installation in March 2015.

This reduction in electricity consumption is one of PhilCorr’s energy management goals. The corrugated sheet feeder already generates nearly half of its total power via a 1.2-megawatt rooftop solar system made up of 3,584 fixed panels covering roughly 77,000 sq ft. By significantly reducing its reliance on power from the Vineland Electric grid, PhilCorr is using the WPS Global system to further its sustainability initiatives. PhilCorr will consume fewer fossil fuels and reduce its emissions as a result.

The reduction in total electricity consumption is making the sheet-feeder’s solar equipment have an even larger impact. Over the five-month period, the percentage of solar generated electricity, versus purchased, jumped to 52%. Without the reduction in electrical usage, PhilCorr's same solar equipment would have only produced 47% of its electrical usage.

As an added benefit, the WPS Global install protects PhilCorr’s equipment from electrical spikes and surges. “Since the install, we’ve had no loss of drives,” says Daniel Santhouse, operations manager, PhilCorr. “And, we had no loss of equipment following a direct lightning strike on a nearby transformer.”

The WPS Global system is designed to benefit high consumers of energy (facilities operating large equipment such as corrugators) with greater savings by reducing kilowatt consumption. The custom-designed plan WPS Global prepared for PhilCorr required no equipment or process changes and no investment in resources.

This email address is being protected from spambots. You need JavaScript enabled to view it.