On Print | Add Extended Gamut Printing to Your Lean List

- Published: December 18, 2012, By Dene H. Taylor

Replacing spot colors with an extended gamut ink set offers the conventional printer substantial savings in time and materials, and at the same time, eliminates inventories of inks and cylinders or plates. Clearly these are objectives of lean manufacturing.

The concept of extended gamut is not new in itself. What is new is that the advances in color control and image handling software have made it accessible to the average owner who has a six- or seven-station printer or press, i.e., most packaging and labeling lines, and all inkjet printers with light color capability.

Furthermore, the Sonoco Inst. of Packaging Design and Graphics at Clemson Univ. runs seminars for those wishing to explore or use this technology—as we all know, getting the benefits from purchased technology requires training the people who will operate it.

Spot Colors vs. Extended Gamut

Digital printers seldom run spot colors because they are special order, and their delivery takes days or even weeks. In the case of inkjet printers, ink changeovers take time, which counters a major reason for going digital in the first place.

Spot inks frequently are used to produce colors outside the standard SWOP gamut. I learned to expand the gamut of my Mimaki JV4s by running cyan, magenta, yellow, and black (CMYK) at high density and printing very slowly. This is a common option with ultraviolet-cure inks. But it is at best a partial solution, and not all colors are obtained—remember that spots are frequently added for visual effect, so they have high saturation, i.e., where standard process mixed colors are limited.

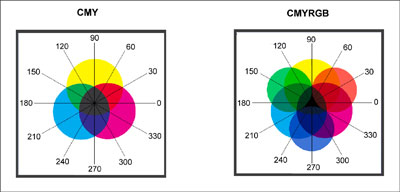

The solution for digital printing has been the use of extended (enhanced or expanded) gamut ink sets, which supplement CMYK with red, green, and blue (RGB) or orange, green, and violet (OGV) (see Figure 1).

The OEMs supporting large format printing for point-of-purchase and outdoor advertising have been including extended gamut capability in their machines for several years. Agfa was an earlier adopter, offering this option for its now discontinued Dotrix, a roll-to-roll press. I expect the expanded gamut option will become more available for packaging and labeling presses—a necessary step if digital is to make the inroads pundits describe.

Obviously for an expanded gamut ink system, high performance inks and toners are needed. And of course, there must be additional print stations on the press. These have been comparatively straightforward to produce—the capability had been developed with oscillating head inkjet, at least for the inclusion of light colors (lc, lm, ly, and lk). The other key to success has been the development of new software—especially for the separations, of which there are more, and which are not necessarily inherent in the image preparation software. Adobe Illustrator, for example, may require plug-ins. But there are hundreds of extended gamut wide and grand format inkjet printers in the field, and so the technology is widespread.

Spot colors are ubiquitous with offset, gravure, and flexography, especially for advertising and packaging. Because they are expensive, there has always been an interest in doing something more cost effective. Pantone tried this with its Hexachrome technology some years back. It was not a great success, due in part to the weakness of on-press color control, especially beyond CMYK. With extended gamut there are six or seven colors to be controlled, and unlike CMYK, the color adjustments are not inherently understood. Fortunately computer-controlled on-press color control is now far more prevalent and much more sophisticated. For those companies now run with tight control, the difficulty of the change should be seen as manageable and its implementation as predictable.

Printing and Proofing

Running a balanced expanded gamut ink set is relatively simple in principle. It’s similar to running SWOP—all inks are run to the same maximum saturation 1evel. For example, with the ideal flexo press, all anilox rolls will have the same cell pattern, and once it is established, the ink strength is controlled within tight limits. An additional benefit of an extended gamut set is that there is greater saturation for the colors produced by overlapping colors, so the individual colors need not be printed as intensely because the color being built up from several primaries. Indeed, when a test trip is run with just CMY or RGB, it appears washed out. But when printed together, they are very vibrant.

Proofing for extended gamut on conventional presses is, of course, essential and has its own challenges. The software and prepress company Esko has filled this gap by adapting Epson eight- and ten-color inkjet printers. Indeed, it was by following a reference to extended gamut proofing by inkjet that I discovered Opaltone, whose main business is selling CMYRGB systems for flexo, gravure, and offset. Opaltone displayed its version of the Epson proofing printer at the IMI/AWA Digital Printing World 2012 Conference in January. Experts at the conference agreed that the output from Opaltone’s proofer was remarkable. Inkjet proofing and prototyping can be done with any of the printers that have six, seven, or more channels, including all those that can run the light colors (CMYKlclmlylk). The inks to do this are available from the key vendors.

Lean manufacturing benefits

Now that the technology is available and tested, it is perhaps surprising that its adoption is so limited. Certainly the benefits for the printer are clear:

- No ink changes—just plates or cylinders.

- No spot ink inventory—no need to dispose of remnants or old stock.

- All color adjustments are made rapidly on press—no need to stop and wait for color adjustment.

As for the clients, they get faster turnaround, lower costs for small runs, and greater consistency across the board. All these factors fit with the goals and benefits of lean manufacturing initiatives. In conclusion, anyone running spot colors and practicing lean manufacturing should take a look at extended gamut ink sets.

Coming back to digital printers, I find it surprising that there is so little activity with presses for labels and flexible packaging. Prototype and Production Systems Inc. manufactures roll-to-roll inkjet printers up to 36 in. wide. Six heads is a standard arrangement, and although white and clear are the common extra inks, extended color sets are available. The 6-in.-wide INX Evolve NW140 has seven stations, so it might be used for six-color extended gamut inks (e.g., CMYRGB or CMYKOV) with the seventh channel used for white or primer in the first position or overprint varnish in the last.

Education and training is the final leg on which new technology adoptions stand. The Sonoco Inst. of Packaging Design and Graphics at Clemson Univ. holds seminars on extended gamut printing periodically. The most recent one was sold out. The next one likely will be in March or April 2013. The institute conducts its demonstrations using design and management software, plus computer-to-plate systems from Esko, with inks from Environmental Inks on its OMET VaryFlex 530 seven-color flexo press. An Epson Stylus is configured with a matching ink set for proofing. Other vendors are encouraged to participate.

For more information check the following websites:

- Opaltone (It includes a list of users and qualified ink vendors)

- Sonoco Inst. of Packaging Design and Graphics

- Esko

- Environmental Inks

Printing expert Dene Taylor, PhD, founded Specialty Papers & Films Inc. (SPF-Inc.), New Hope, PA, in 2000 for clients seeking consultation for technical management, new product design, development, commercialization, and distribution, as well as locating/managing outsourced manufacturing. Contact him at 215-862-9434; This email address is being protected from spambots. You need JavaScript enabled to view it.; www.spf-inc.com.