Water-Based Flexographic Printing Steps Up to the Sustainability Challenge

- Published: July 01, 2021

By Takumi Saito, Printing Solutions Project, Asahi Kasei Corporation

The recent Leaders Summit on Climate, hosted by U.S. President Biden, demonstrates the growing commitment leaders of many countries have to addressing the climate crisis by reducing greenhouse gas (GHG) among other initiatives. This will likely translate into increased regulatory pressure on a variety of industries, including printing, to moderate their emissions of CO2 and other global warming gases such as CH4 and N2O. As a leading supplier to the flexographic printing industry, Asahi Photoproducts is dedicated to delivering flexographic solutions that are in harmony with the environment. In doing so, the company enables its customers to be proactive in contributing to the overall reduction of GHG emissions

Over the last half century, Asahi Photoproducts has worked hard to bring innovative solutions to flexography, and most recently with the Asahi AWP™ CleanPrint water-washable plates. This solvent-free process delivers more sustainable printing while at the same time improving Overall Equipment Effectiveness (OEE) in the press room to the tune of 30 percent or more, which results in a significant increase in quality due to the precise register these plates deliver.

What that means for the printing industry is that flexography is now competitive with gravure for all except the longest print runs. To validate this assertion, Flexo Technical Association Japan (FTAJ) and Water-based Flexographic Printing Advancement Council partnered with the Sustainable Management Promotion Organization (SuMPO), a well-known Japanese association, to calculate GHG emissions during the entire printing process for each of these two technologies, using the Life Cycle Assessment method.

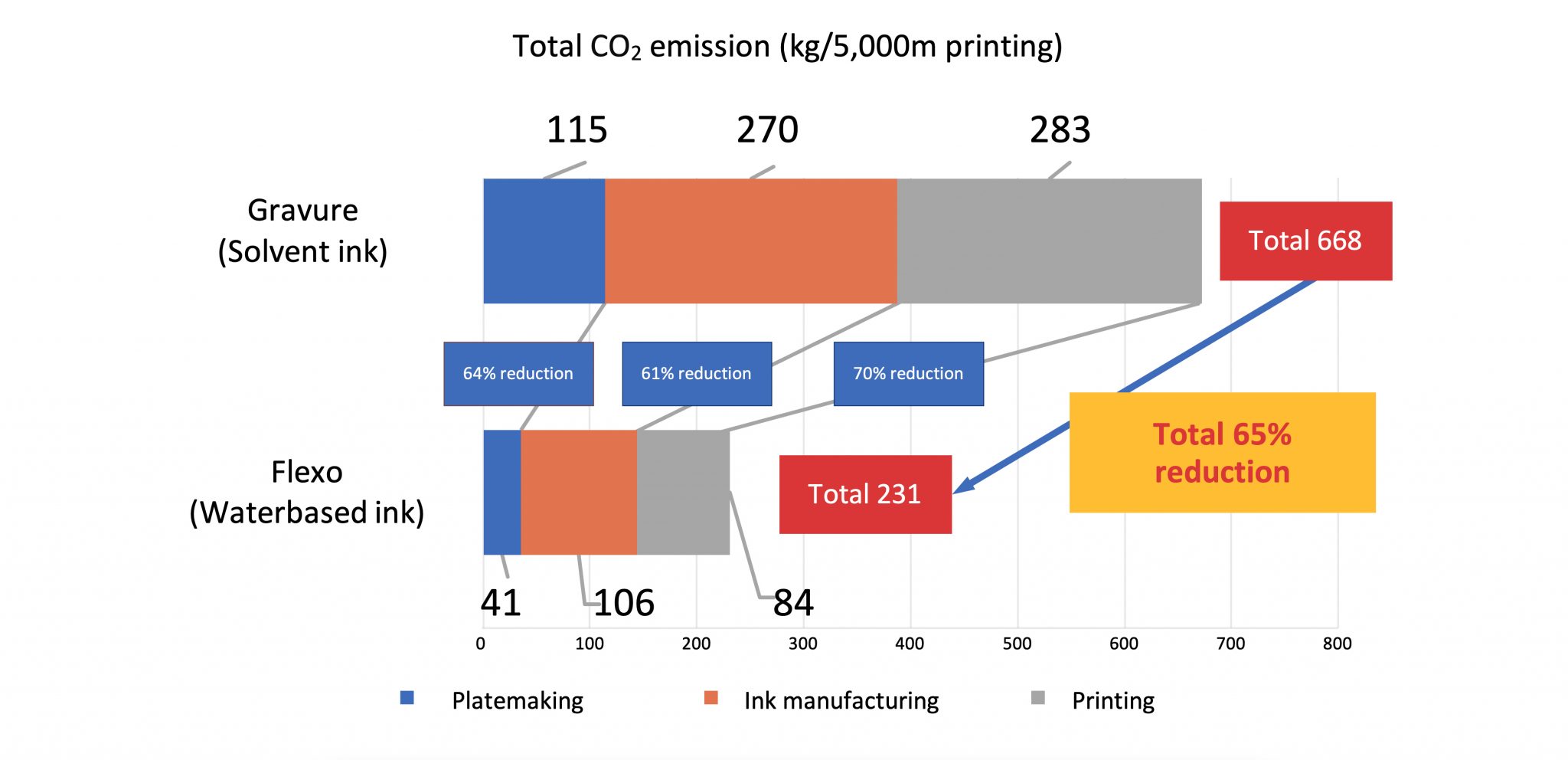

The results were enlightening. We found that when printing a job of 5,000 linear meters with water-based flexographic printing and comparing the result with the simulation of the same job with gravure printing, GHG emissions from water-based flexographic printing can be reduced by about 65 percent compared to gravure. We measured GHG emissions from the gravure life cycle at 668 kilograms, whereas emissions from water-based flexography were 231 kilograms.

The gravure printing simulation results from using electronic engraving of the cylinders and solvent-based inks, while water-based flexographic printing uses water-washable plates and water-based inks. The results are shown in the image below, broken down into 3 steps: platemaking/engraving, ink manufacturing, and printing.

The sustainability of the print can be further enhanced by using solvent-free laminating where lamination is required or desired, instead of dry lamination where the bonding agent is dissolved in solvent, applied, and then evaporated in a drying oven. With solvent-free lamination, a low viscosity adhesive is applied, requiring only a heated nip to mate it to the substrate. This creates an additional advantage of solvent-free lamination beyond the reduced GHG and VOC emissions since it does not require a drying component, further reducing energy consumption and increasing its sustainability as compared to the conventional dry lamination process. Thus, we recommend water-based flexographic printing technology combined with solvent-free lamination and water-washable flexographic printing plates as the most sustainable approach to producing packaging.

All of this demonstrates the significant progress that has been made towards reduction of the carbon footprint for flexographic printing as compared to gravure, and the fact that this approach to packaging printing has the potential to change the global packaging market. But we are not stopping here. The talented and innovative engineers at Asahi Photoproducts continue to seek new ways to reduce the environmental impact of flexographic printing processes even further, and we have full confidence that they will find even more ways to make flexographic printing more sustainable.

Ref.1: Calculation Assumptions by Sustainable Management Promotion Organization (SuMPO).

- Film substrate and packaging process are not included in this calculation since there is no difference in-between water-based flexo printing and solvent gravure printing at them;

- This calculation is done by 5 colors printing;

- Plate making processes are: water washable plate technology for flexo printing, electronic engraving technology for gravure printing;

- Utility data at printing machine is based on typical and theoretical data on product catalogue since actual utility can be fluctuated as per actual printing condition and environment;

- Printing speeds are: water-based flexo 200meters/minute, solvent gravure 150meters/minute;

- Disposal method of printing wastages are: water disposal at water-based flexo, incineration at solvent gravure;

- Plate sleeve at flexo printing and steel cylinder at gravure printing are part of printing machine and not included in this calculation;

- Proofing process is not included in this calculation;

- GHG emissions of ink manufacturing are based on published data of Japan Printing Ink Makers Association*[1];

- Transportation of intermediates and wastage are, 500 kilometers for intermediates, 100 kilometers for wastage respectively; and

- LCI Database IDEAv2.3 is used *[2].

For more information, visit https://www.asahi-photoproducts.com.

[1] Note 1: “CFP value of each ink type” released by Japan Printing Ink Makers Association.

[2] Note 2: LCI database IDEA version 2.3, released by National Institute of Advanced Industrial Science and Technology, LCA study group, Sustainable Management Promotion Organization