Why LED is the Only Sustainable Choice for UV Curing

- Published: September 26, 2022

By Stacy Hoge, Marketing Communications Manager, Phoseon Technology

Today, all the major brands are requiring their suppliers to deliver more sustainable printing practices. The environmental benefits of UV LED curing in the printing process are numerous and significant. UV LED brings energy savings, reduces waste and prevents pollution for users all over the world.

With traditional UV curing processes, the tremendous heat associated with mercury UV lamps required a lot of electricity to operate. In addition to high amounts of electricity, these bulbs need to be replaced frequently, generating a high amount of waste. If built correctly, LED curing systems have a very long lifetime of up to 60,000 hours and require zero bulb replacements. The mercury lamps produce ozone, which is dangerous to breathe, especially in a constricted space like a print shop. Air exhaust systems are required to extract the toxic fumes from the presses. These exhaust systems can be eliminated with UV LED curing, making it a far more environmentally friendly process.

Energy Savings

Traditional UV curing processes require a significant amount of electricity to operate, making the electricity bill very high. UV LED technologies provide energy savings up to 85 percent compared to traditional drying systems. With LED curing, there is no need for fume extraction units to remove the gases generated by mercury-vapor UV lamps. UV LED is not only good for the environment, but also has a very positive effect on the finances, sustainability, health and safety of company operations.

As an example, family-run printing company Eticod from Katowice, Poland, focused on the sustainable production of labels at an early stage and has already invested in photovoltaic systems and heat exchangers in the past. With the investment in UV LED for drying, the CO2 emissions at Eticod have been reduced even further while energy savings have increased.

Eticod’s Bobst M5 430, 10-color press with UV LED curing was successfully installed and put into operation. The machine consumes approximately 60 percent less electricity, which corresponds to an annual saving of some 50 kWh, while eliminating 200 tons of CO2.

Pollution Prevention

UV LED lamps offer better than 50 percent lower CO2 emissions. UV LED lamps generate no ozone and offer the promise of eliminating toxic mercury in an entire category of industrial processes. With UV LED lamps, there is no need for fume extraction units to remove the harmful gases and Ozone generated by mercury-vapor UV lamps.

With LED systems, converters can diversify their product lines and enter new markets without having to expand their floor space or expose employees to volatile organic compounds (VOCs) harmful UV-C ozone. By removing UV mercury stations and upgrading to LED lamps, users can reduce up to 200 tons of CO2 annually per press. Users do not need to re-integrate into the building the millions of cubic meters of air extracted every year to remove ozone and heat produced by the mercury lamps.

Waste Reduction

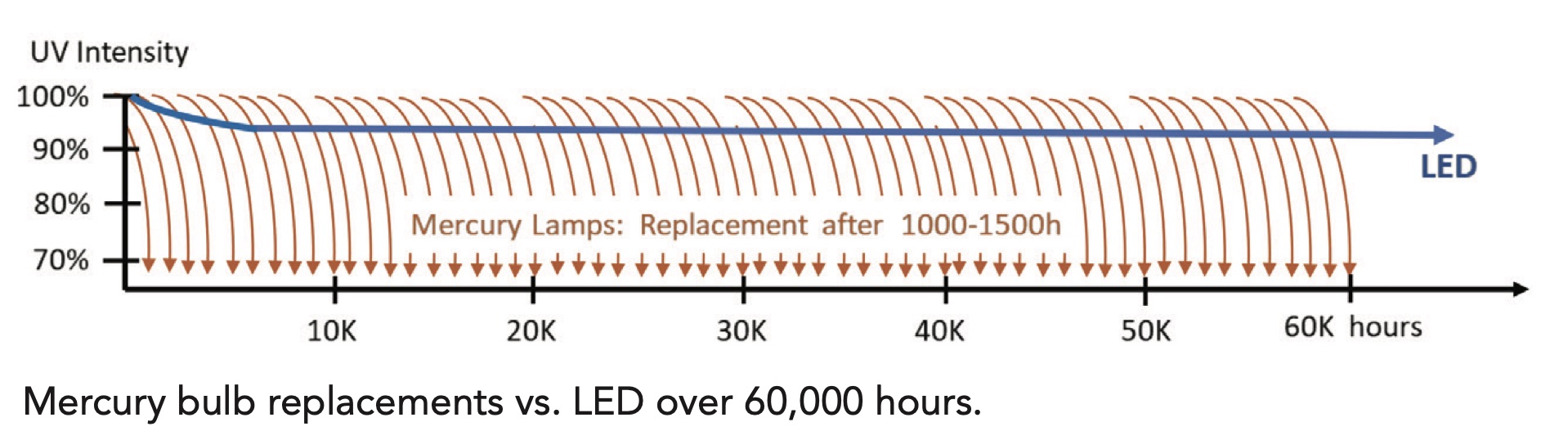

Conventional mercury lamps have a very short lifetime and need to be replaced every 1,000-1,500 hours. LED curing lamps extend beyond 60,000 hours if maintained properly. Upgrading to UV LED technology eliminates these replacement costs, offering significant environmental benefits with the elimination of mercury.

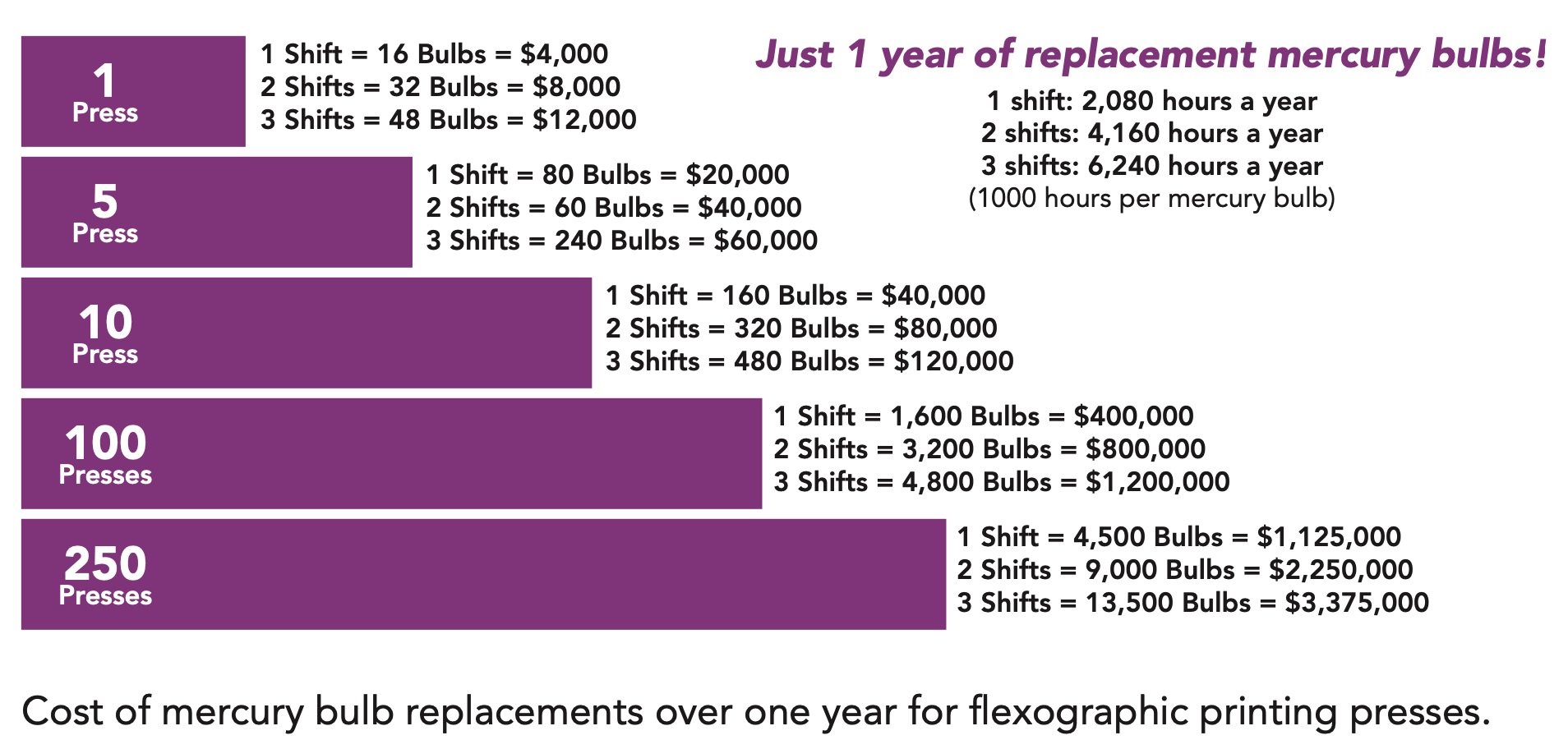

Central Valley Label in California experienced significant operational cost savings by upgrading from mercury to LED. Before switching to UV LED curing technology, Central Valley Label was spending $40,000 to $50,000 per year on UV bulb replacement for their old UV mercury presses. When the company switched to the UV LED solution, that expense was eliminated.

Initial Investment Costs: Mercury vs. LED

Although the initial costs of mercury may be lower than LED, the long-term costs for mercury are much higher. The initial investment for LED might be slightly higher or the same as mercury, but all the additional costs required for mercury add up over time. The long-term costs for LED after installation, on the other hand, are zero.

- Mercury UV costs continue to mount over the life of the system.

- Consumables (bulbs, reflectors, lenses, shutters, dichroic filters, etc.) are a significant revenue stream for mercury UV manufacturers.

- Lost production, lost substrate and reoccurring consumable expenses erode the profitability of the converter.

UV LED has little maintenance, no consumables and predictable performance.

- UV LED allows the converter to focus on their work and increase profitability of the converter.

- Constant, repeatable and predictable.

The Cost of Mercury Bulb Replacements

When investigating a new curing system, make sure to look at the long-term costs of mercury bulb replacements and other costs that add up over time. Mercury UV continues to significantly impact your bottom line for the lifetime of the system.

Legislation

The Minamata Convention on Mercury is a global treaty to protect human health and the environment from the adverse effects of mercury.

Major highlights of the Minamata Convention include a ban on new mercury mines, the phase-out of existing ones, the phase out and phase down of mercury use in a number of products and processes, control measures on emissions to air and on releases to land and water, and the regulation of the informal sector of artisanal and small-scale gold mining.

The Convention also addresses interim storage of mercury and its disposal once it becomes waste, sites contaminated by mercury as well as health issues.

- Minamata Convention became law in 2017 in the European Union and many other countries. Today, the Minamata Convention is currently joined by 127 countries.

- 2020 was a key year for the Minamata Convention as the deadline for mercury-added products.

- Parties shall not allow, by taking appropriate measures, the manufacture, import or export of mercury-added products listed in Part I of Annex A after 2020.

- Some countries have already banned the mining of mercury.

- Use of mercury in some products already banned.

Conclusion

UV LED curing technology offers equipment manufacturers a high-performance curing technology that also saves significant energy while eliminating greenhouse gases and dangerous mercury and ozone from the UV curing process. UV LED products offer significant environmental improvements compared to traditional mercury-based products.

About the Author

Stacy Hoge joined Phoseon in 2009, bringing more than 10 years of experience in Marketing Communications. Ms. Hoge is responsible for the Marketing Communications strategy and implementation at Phoseon Technology. She holds a bachelors of science degree in both Mass Communications and Psychology from St. Cloud State University in Minnesota.