How to Keep Defects In House

- Published: June 05, 2023

By Alfonse Novelli, President and Founder, Novation, Inc.

Marking and Finding Defects

Although producing zero defects on a print or converting process is a great goal for which to strive, in the real world it is usually an unattainable one. However, preventing defects from reaching your customers is something which should be achievable.

The first part of a “ship no defects” policy is obviously knowing when you’re making an unsaleable product. At times a part of the process itself creates an out-of-spec product. Examples of this would be unwind lap splices, coming off, start-up waste, etc.

Other issues need to be found through inspection. Some are visible and obvious to the naked eye. Some however, are not easily seen by the naked eye, especially at process speeds. Enter 100 percent automatic inspection systems. These systems can inspect for coatweight, printing problems, surface flaws, pinholes, etc.

Other issues need to be found through inspection. Some are visible and obvious to the naked eye. Some however, are not easily seen by the naked eye, especially at process speeds. Enter 100 percent automatic inspection systems. These systems can inspect for coatweight, printing problems, surface flaws, pinholes, etc.

These inspection systems then need to inform the operator that a defect has been recognized. Usually, an alarm light is activated and possibly an audible alarm as well. In this scenario the operator is then tasked with marking the web in some fashion so the defect can be found and removed at the next process.

Some current inspection systems can remember where scrap is within a roll by creating digital roll maps. These roll maps create a powerful data file which pinpoints all the issues found within a roll and records all the locations by a footage count from the start of the roll.

Often, damaged outer wraps of a roll need to be removed when it is next used, and material also has to be removed to cull out all defects. However, without any physical markings on the web, when material is removed from the roll for any reason, the digital information can be rendered useless if it cannot be resynchronized with the physical roll somehow. Physical markings, either as recurring reference points or markings at each defect location, solve this resynchronization problem.

Manual Web Marking

Various methods of manual web marking have been used over the years. These methods include inserting a slip of paper into the winding roll, hand applying a pressure sensitive label to the moving web, or possibly using a felt pen. These methods require an operator to be available to notice the alarm and then react.

This means that by the time the alarm goes off and the operator gets to the location where the web is to be marked, the defect itself could be already wound a hundred feet into the rewinding roll. This inaccuracy in marking makes the subsequent finding and culling out the defects a very inefficient process.

More important than the inefficiencies of hand marking the web is the safety aspect. Hand marking means operators’ hands must be very near or even touching the moving web and rollers. Needless to say, this is a dangerous approach which is prohibited

by the safety protocols of many organizations.

In many cases hand marking of the web is not even an option. The propensity for injuries with these methods have resulted in many lines now being equipped with guarding and interlocks which make it impossible for operators to access the moving web.

Automatic Web Marking

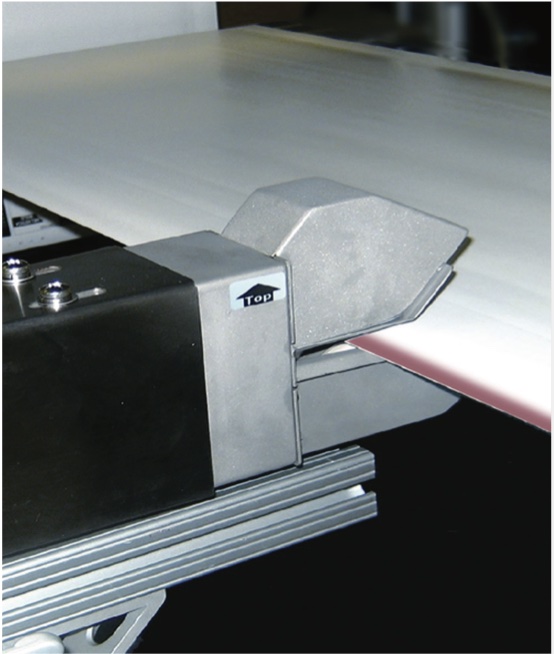

Automatic web marking eliminates accidents by keeping hands away from the moving product and rotating machine components and allows webs on completely guarded machines to be marked. Additionally, marking systems eliminate inaccuracies caused by the delay between the sensing and subsequent hand marking. They are typically located toward the end of the process line, downstream of all automatic inspection devices or manual inspection locations.

Often the inspection systems, which track web motion as part of their function, can even delay their output signal to the web marker so that the mark is not activated until the defect actually reaches the marking system. Some of the markers have a method

of “tracking” an issue noticed at an upstream manual inspection station, signaled by an operator pushbutton entry.

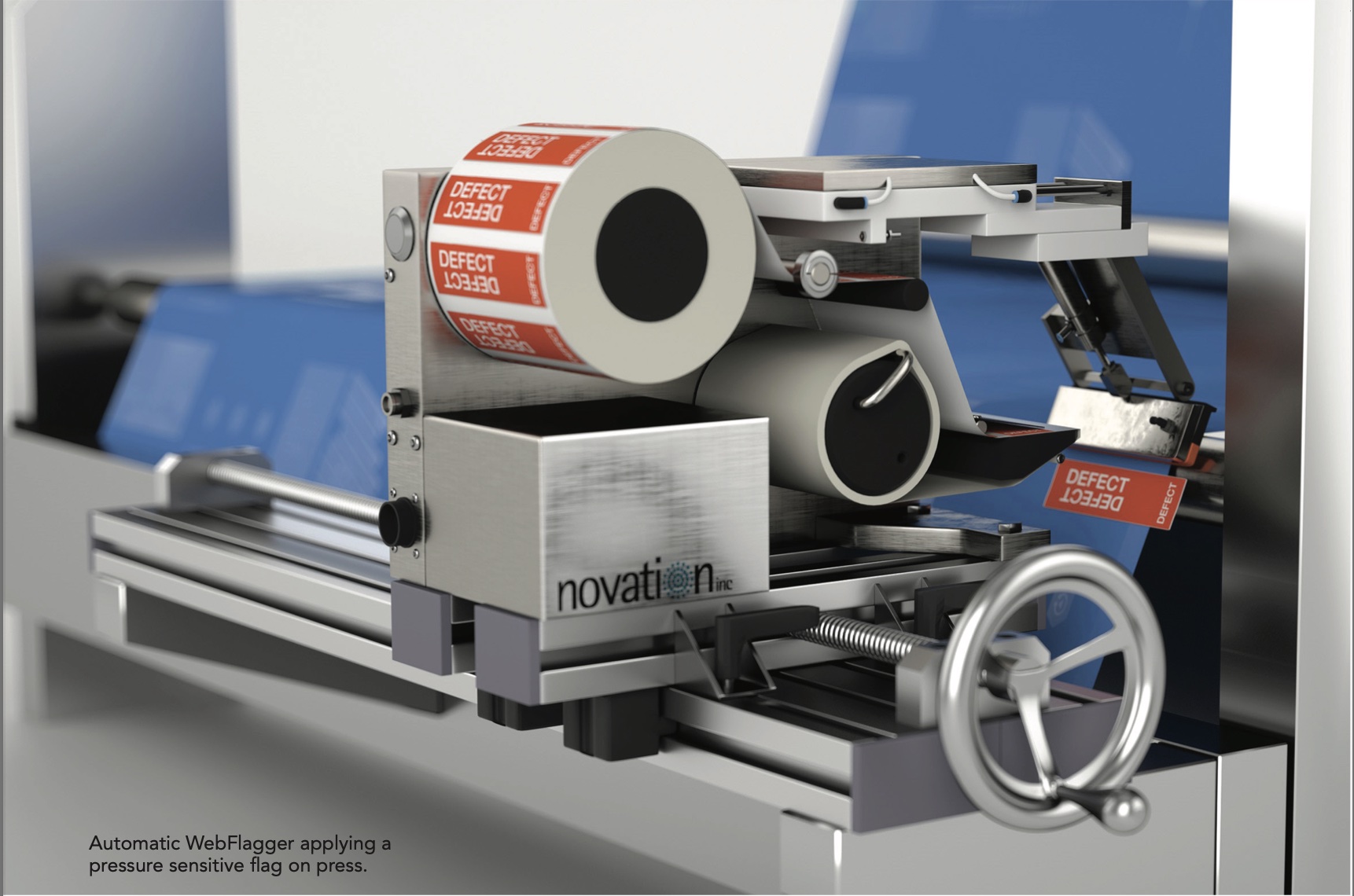

There are two basic methods of automatic web marking in use today. They are, flagging (also called tabbing), and spray marking. WebFlaggers place a pressure sensitive label on the moving web. Typically, a portion of the label has no adhesive, and that portion hangs off the edge of the web like a “flag” making it visible in the wound roll. Spray markers spray the edge of the web with inks. They can place a mark at a particular location, or even color the edge of an entire out-of-spec section of a roll.

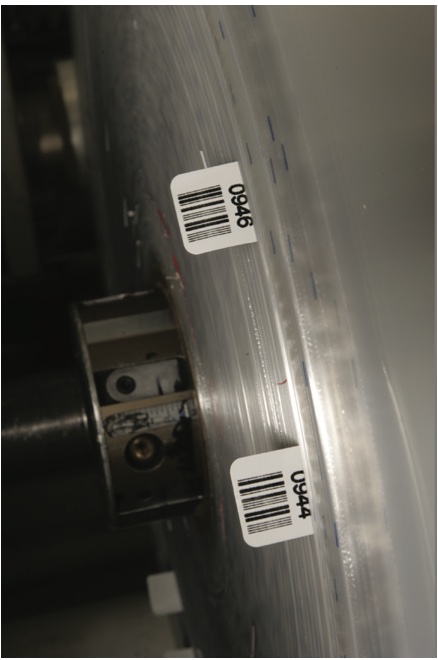

WebFlaggers can apply different color flags to identify the various issues while spray marking systems can spray multiple colors of ink. To coordinate roll locations with a digital roll map, flags can be produced with a sequential numbering and a corresponding bar code so each flag has its own machine readable ID. Spray systems are capable of something similar by encoding a number by marking a sequence of dots on the web’s edge.

WebFlaggers have a limit to how quickly subsequent flags can be applied. This means individual issues located close to each other cannot always all be flagged. Spray markers have a faster reaction time, and therefore don’t have the same limitation. However, the spray marking systems usually require a bit more maintenance than flagging systems.

Permanent vs. Temporary Marking

Once the process has been deemed one which would benefit from a marking system, another decision becomes which type of marking is most appropriate. Some processes have types of scrap which is easily identified and is unquestionably defective. Others may want to mark questionable locations as well and reinspect at a roll edit machine or at the unwind of the next process.

Those with easily identifiable scrap, can and should probably use a permanent marking solution. WebFlaggers can apply flags with very aggressive adhesives which create a destructible bond to the web. They can’t fall off or be easily removed. Ink spraying is also a permanent marking method.

For the processes with questionable defects which need to be reinspected, flags can be produced with removable or “repositionable” style adhesives which can be removed cleanly if the material is subsequently deemed good. Spray systems can use inks invisible to the human eye in these cases.

Conclusion

So, it appears that finding all your flaws is only the first half of keeping your defects in house. Safely, accurately and reliably marking those flaws is the other half of preventing any defects from ever leaving your factory.

About the Author

President and Founder of Novation, Inc. (www.novation-inc.com), Alfonse Novelli’s work experience includes controls engineer with Van Dam Machine Corp. and Fischer and Krecke, and vice-president of Geometric Machine and Design. He studied engineering at University of Connecticut and Fairleigh Dickenson University.