Improve Quality by Corona Treating Films Prior to Converting

- Published: June 26, 2023

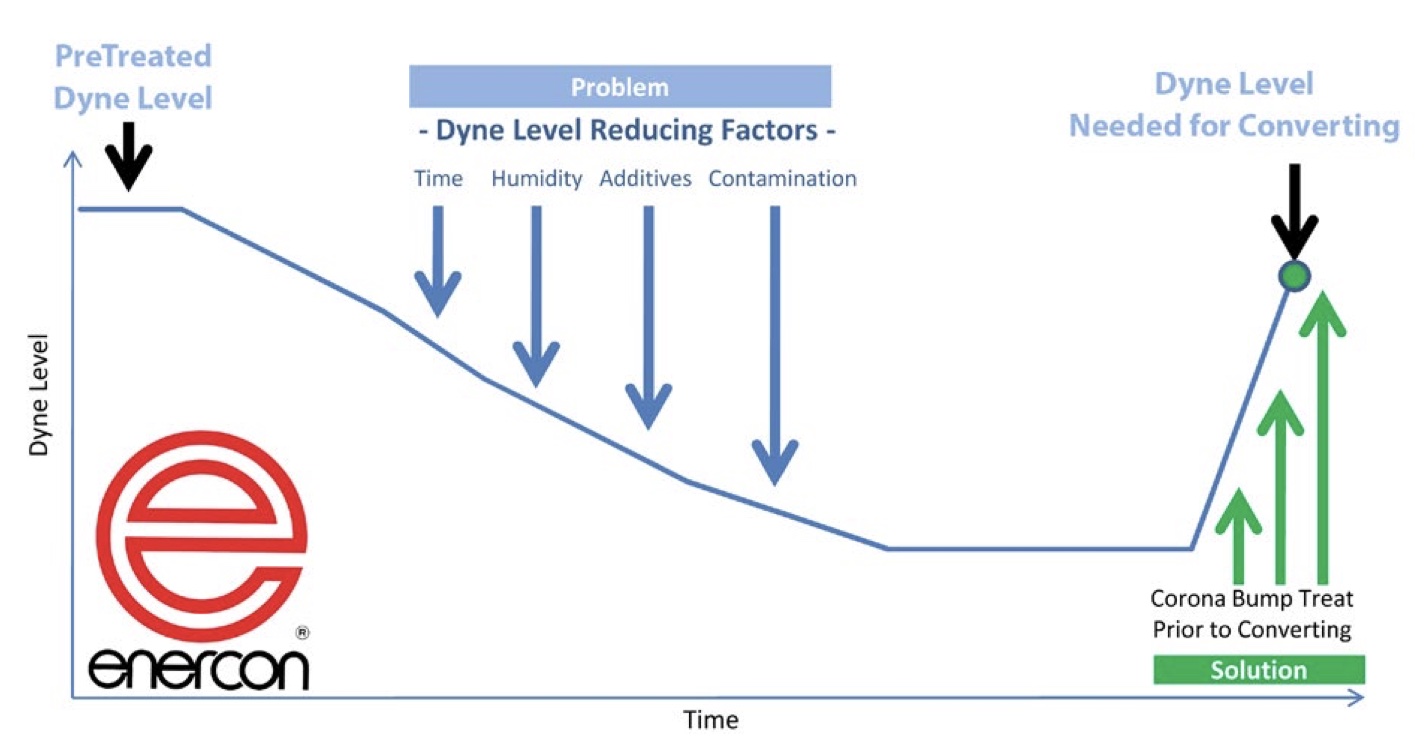

The terms “bump-treating”, “re-treat”, or “refresh treat” refer to treating a film in-line prior to converting. You might wonder why converters need to do this if they purchase pretreated films from film extruders. This secondary treatment is needed because the effects of corona treatment decay over time. It is an industry best practice to treat films at the time of extrusion and again before converting.

Surface Energy & Dyne Decay

The purpose of surface treatment is to improve wettability and increase surface energy to enable adhesion with inks, coatings and laminations. The increase in a film’s surface energy is not permanent. Surface energy decays over time and the rate of decay depends on a variety of factors including the film’s inherent ability to retain surface energy, storage environment, and additives. Additives are used to make the film easier to handle during the converting process. However, when they migrate to a film’s surface they create a barrier to successful adhesion.

What happens if you don’t retreat

If you print, coat or laminate a film with a low surface energy you’re likely to see poor results. You may experience failed adhesion that will literally stop the press. You may see imperfections that your quality control team will catch before you ship the product. Worse yet, your customer may be the first to recognize something is not right with your product.

What Industry Experts Say about Bump Treating

An instructor from a flexographic printing program says, “Films are pretreated, but they’re not guaranteed to be perfect when it comes time to print. Treatment degrades over time so that’s one issue you have to contend with. And, even if the film makes the grade on a dyne test you still have the possibility of additives rising to the surface. These surface imperfections can result in pinholing and other quality issues. A corona treater can help eliminate these problems.”

A Director of Engineering from a company that offers custom coating sees other benefits to bump treating, “There’s something to be said for a fresh treat. Dyne level does not always guarantee adhesion. Dyne level is simply a measurement of wetting-out. We’ve seen materials with equal dyne levels, one freshly treated and one from inventory and the freshly treated material consistently provides the better adhesion.”

Surface treatment is often associated with water-based applications, however solvent applications also benefit from bump treating solvent processes as well. One solvent printing Operations Manager recently told us, “There’s no doubt that our lines with corona treaters have less delays and downtime. The treaters provide a safety net that assures surface dyne levels are optimal for printing.”

Take control of you operation

By following the industry best practice of treating in-line prior to printing, coating or laminating converters can eliminate surface energy as a process variable. With a corona treater your operating window for success greatly expands.

Which corona treater design will work best for your application? Most converters choose Enercon’s High DefinitionTM corona generated by high powered ceramic electrodes and a proprietary ground roll covering that is effective at treating both conductive and nonconductive films. Enercon’s New CompakTM Pro corona treater power supplies are also making it easier for operations. Simple to use touch screen interfaces provide smart features that help operators set up, control and troubleshoot corona treating operations for reliable results.