Independent II ‘Experience Packaging Success’ with Domino

- Published: November 30, 2023

Independent II, in Louisville, KY USA, is a privately-owned and operated corrugated manufacturer, providing total packaging solutions to their customers. Independent II designs, manufactures, warehouses, and delivers corrugated and packaging that protect their customers’ products in-transit and sells them on shelves.

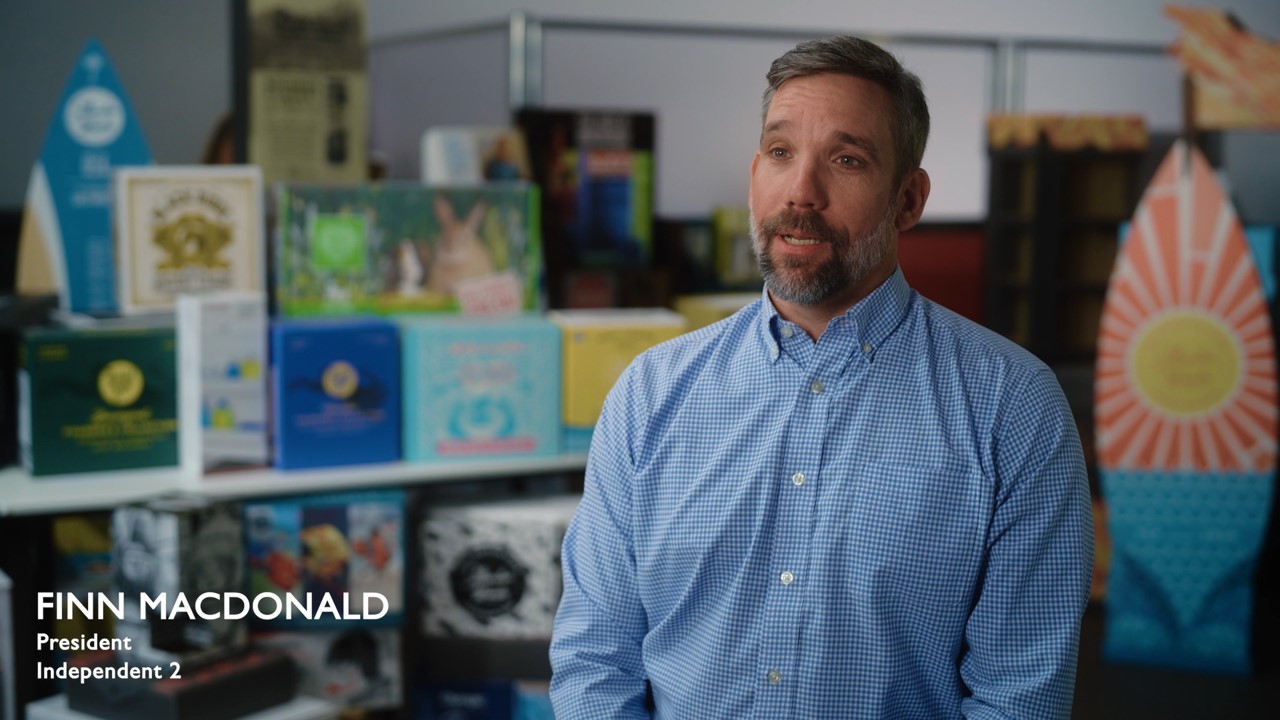

We caught up with Finn MacDonald, president of Independent II, in a brand-new state-of-the-art facility to learn more about how his business is changing and growing with the Domino X630i digital aqueous inkjet corrugated press. Our visit was captured in this VIDEO: Finn MacDonald on ‘The Domino Digital Advantage’

Experience Packaging Success

Finn begins, “Our motto is ‘Experience Packaging Success’. That's what we’ve brought to our market for close to 60 years now, and the constants are quality, service, and consistency in relationship…all included in the cost of the box. But there's been some incredible changes. Independent has moved into a brand-new facility. We are now 340,000 square feet under one roof, and really what we're changing is from a brown box manufacturer to a brand box and a digital box performer. Our vision was relatively simple… diversify from brown box, but do it in a way that would deliver consistent value and quality to our customers. And it was something that was achievable for us to manage every day.”

Everyday Digital

“Everyday digital is really the philosophy that drove my vision for getting digital to our company, and into our market. When Domino came out with the X630i single pass aqueous-based digital press, we said ‘that's it.’ For us, it's really as simple as sell it, rip it, and print it… it’s that easy. You've got a ton of potential, a ton of capacity, and great innovation to make use of. This is the type of press that we can install in the middle of our converting facility. You don’t need a clean room. You don’t need a lot of special air filtration. You don't need a lot of special concrete build up floor placement. You've got arguably the most compact press on the market, so it's going to get a whole lot done in a very small footprint. So as far as single pass aqueous-based, there aren't any players who have a machine like this press available.”

“What it brings to our customers is the ability to think about color. Think about variation. Think about changing your message to your need. And that is really something that we think allows everyday digital to be something that our production team can manage on a Domino press. We have two operators who have zero longtime experience in corrugated. What they do have is hustle. They don't like the frustration of managing work, but they like to show up and get a lot done.”

The Domino Difference

“Working with Domino made that jump really easy. You're not jumping alone, you're with a partner. They have a slogan that says there's a ‘Domino difference’, and I'll tell you that it's absolutely true. It is a relationship that is honest. It's built on being humble. And there's a lot of trust involved. So, when you think about the investment in digital, I would say don't think about an incremental jump. I would say have a bold vision, take a big step, trust Domino to help get you forward faster… with more color, and more pop, and more fun than any other option you got out there.”

To learn more about the Domino X630i corrugated press, visit: Domino X630i.