Hierarchy of Value: Part II

- Published: November 01, 2007, By By David Argent Contributing Editor

Process Management

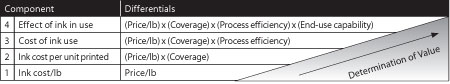

Last month's column offered a value model as a way of visualizing the value of a product or service based on price/performance ratio. Marketing of ink and related services is used as an example, but the concept can be extended to other areas of the converting industry.

At Level 1 (described last month), the Ink Cost per Pound is very measurable but has no information on actual performance. It is simply a price list. So, we need to add some parameters to further define value delivered.

Level 2: Ink Cost per Printed Unit

Unfortunately for the Level 1 buyer, there are very few cases in which inks are completely interchangeable. In the next level of value measurement, we consider that ink companies can make inks at all different strength levels. The amount of pigment in the ink has the greatest impact on color strength and subsequent mileage obtained. It also has the greatest impact on raw material cost of the ink.

Simply put, you will consume fewer pounds of a stronger, more highly pigmented, more expensive ink for a particular job. And therein is the need to factor in Ink Cost per Printed Unit and consider the combination of mileage and price to determine the value.

One way to measure ink mileage is by material balance on an individual job, where the amount of ink consumed is actually recorded for a press run having a specific number of impressions. Inks with higher mileage produce more impressions per pound of ink. Knowing the price per pound of ink, a calculation can be made of ink cost per unit printed. Other gross measures already may be in place, such as annual ink usage in pounds and dollars and annual total unit throughput.

Level 3: Cost of Ink Use

At the next value level we include the cost of product impact on the converter's process. For example, a press usually is valued by converters at many hundred dollars/hr, and equipment utilization comes into effect. Here are three critical factors that need to be quantified when assigning value to a product:

- Press speed at which good product can be printed

- Ease of cleanup and speed of job changeover

- Level of substrate waste associated with using the product.

Level 4: Effect in Use

At this level of customer-supplier interaction, strategic planning comes into play and some hard questions have to be addressed, such as:

- Do ink factors currently limit the ability to satisfy converter customers?

- Are there markets the converter cant access because of ink factors?

- Is converting equipment being installed requiring new ink technology?

There are two different realities, depending on whether you are the supplier or the customer in the value chain. The supplier naturally wants to be paid based on product and services delivered and must provide objective evidence in support. The customer needs to ensure that the price paid reflects value delivered. In both cases the participants need to know where they are in the value hierarchy.

Click to read Hierarchy of Value Part I.

Process improvement expert David Argent has 30+ years of experience in process analysis with particular emphasis on ink and coating design and performance. Contact him at 636/391-8180; This email address is being protected from spambots. You need JavaScript enabled to view it..