The Feat of the Foam

- Published: May 08, 2023

Defeating Foaming in your Aqueous Coating without Additives

Foaming is a pesky problem many printers battle throughout their web coating applications. There are multiple factors that can cause the aeration of your aqueous coatings during production. Ink pumps, doctor blades, end seals and anilox rolls are often the top culprits of foaming in your system. In this article, we’ll walk through each of these components to help find and defeat the source of your coating foam, without the need for de-foaming additives that could impact coating quality.

Is it the Pump?

Aqueous coating, in itself, does not foam. It is when coating moves through the delivery system that it can start foaming. The first step when resolving foaming issues is to check your delivery pumps.

If using a centrifugal pump, having a top fed pump sucking up air may be the source of your problem. Bottom feeding your centrifugal pump and maintaining coating levels, with the appropriate amount of clearance, can help avoid aeration in the system. If using a peristaltic pump, ensure the pump tubes are long enough and your coating levels remain high to ensure no air is sucked through.

Foaming can occur in both your pump intake and outfeed. When coating is returning to the chamber, check that the return line is submerged deep enough in the reservoir, so it is not splashing at high velocity, causing foaming.

Is it the Consumables?

By taking these measures with your pumping system, air in the delivery system can be greatly reduced or even eliminated. However, the pumping system is not the only place that can allow air to enter. Doctor blades and end seal quality, along with the pressure of the system, can cause aeration during coating laydown.

An easy fix, check your end seals for any wear and tear that may be allowing air into the system. End seals are used in chambered doctoring systems and keep an air-tight seal on the sides of the chamber. If this seal is broken or damaged, air can leak into the chamber and cause foaming in your coating. It’s important that your end seals are the right material for your coating and are evaluated and replaced regularly.

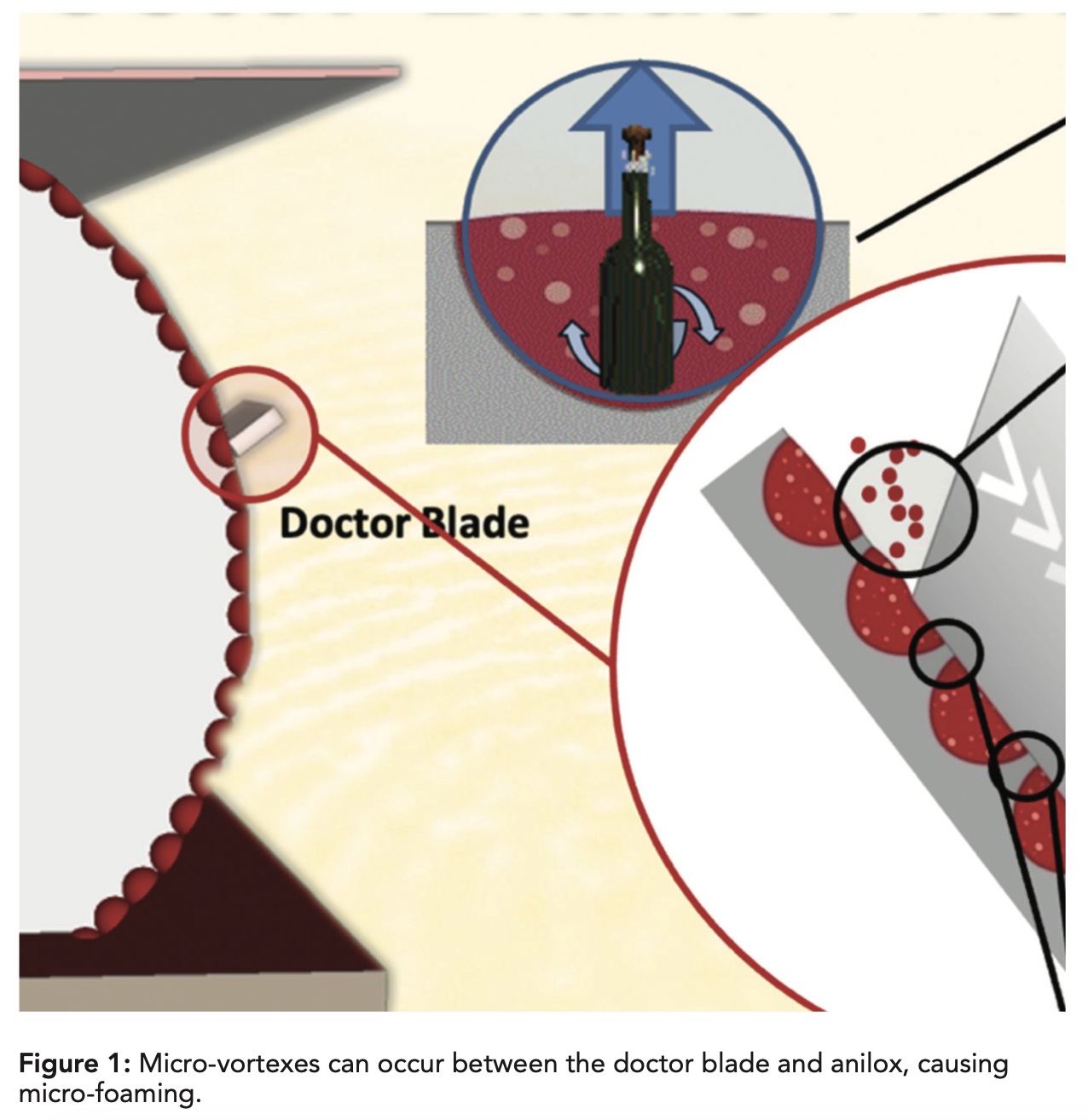

Doctor blades are designed to wipe excess coating from the anilox for a uniform laydown. During this wiping action, micro-vortexes can occur within traditional 60-degree hex anilox cells, causing air bubbles to form within the cells (Figure 1). Accentuated by higher press speeds and larger cell dimensions, this micro-foaming between the blade and the anilox can cause defects in your coating. Re-evaluate your doctor blade material type, blade angle, blade tip geometry and the doctor blade-to-anilox pressure to find the right specifications to reduce aeration and foaming in your system. If these steps have been taken and your coating is still foaming, it’s time to evaluate your anilox roll.

Is it the Anilox?

The anilox roll is one of the most important components of the flexo printing process. Its cells carry a measured amount of coating from the pressurized doctor chamber and transfer the coating onto the printing plate or print substrate, depending on your application.

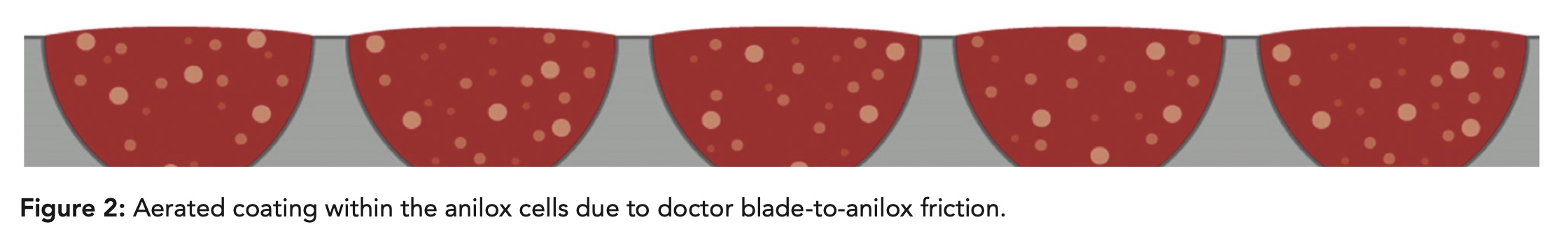

It has been established, that even when you can ensure there are no sources of air leaks or suction within the circulation system, the problem of aeration can still occur in the anilox-to-doctor blade interaction during print production (Figure 2).

Aerated coating in the doctoring chamber results in a combination of coating and air being deposited onto the printing plate surface. This will impact quality and performance, causing defects such as pinholing and a dull coating appearance.

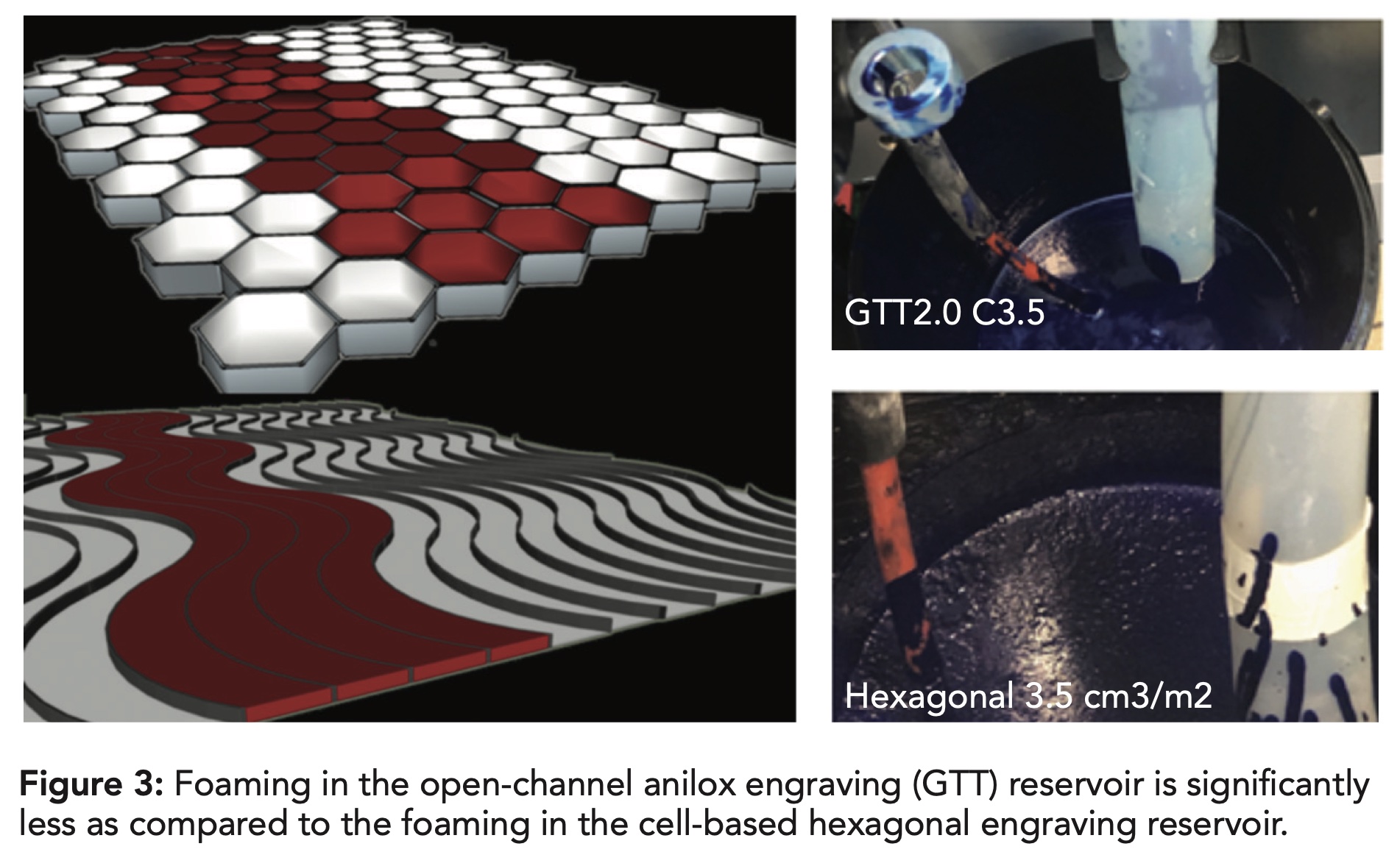

To tackle aeration at the root anilox cause, Apex International evaluated an open cell structure anilox engraving, the patented GTT anilox engraving. Completed through an independent third-party testing partner, Apex found that this open cell structure eliminates the friction between the doctor blade, coating and the HEX cell walls.

This open slalom channel geometry significantly reduces the formation of micro-air bubbles in the anilox cells and improves coating laydown and quality.

The tests as conducted were designed to create the ideal circulation situation so that the foaming reported was likely only the result of the different screen-roll screenings and not influenced by the metering system. With all factors controlled, the tests were completed on a traditional 60-degree HEX anilox roll and a comparable open channel anilox roll; and the results were clear.

When all print variables are at their optimal specifications, using an anilox engraved with an open channel structure will significantly reduce, if not eliminate, foaming in your coatings (Figure 3).

Fight the Foam!

Fighting the issue of foaming should not be a win that causes you to lose on coating quality or press performance. Utilizing these troubleshooting tips can help you quickly diagnose and solve the source of your foaming issues, without using de-foaming agents.

Evaluating your pumps, consumables and potentially switching your anilox engraving will help you fight the foam, while achieving high press speeds and high profit margins. Fight the good fight, friends!

About the Author

Farrah Nuzzo has been providing industry-leading solutions with Apex International (www.apex-international.com) for more than 15 years. With seven production facilities on four continents, a strong portfolio of clients in over 110 countries and a high-performance continuous improvement culture, Apex’s value proposition is founded on developing solutions to satisfy the complex challenges its customers face every day.