Enhancing Battery Production with Advanced Cleaning and Static Control

- Published: September 30, 2024

In battery production, maintaining cleanliness and controlling static electricity are essential to ensuring quality and efficiency. Even microscopic contaminants can lead to defects, affecting battery performance and safety. Simco-Ion, a leader in static control, and Teknek, a pioneer in web cleaning technology, collaborate to deliver comprehensive solutions that address these challenges.

The Impact of Contaminants

Battery cells consist of electrodes, a separator and an electrolyte that enables ion movement between the electrodes. This movement is crucial for the battery's performance. Contaminants, such as dust or metallic particles, can disrupt this process. For example, metallic particles might cause short circuits or self-discharge, leading to battery failure or even dangerous situations like overheating and fires. Non-metallic particles can also block ion flow, reducing battery efficiency and lifespan.

Advanced Cleaning and Static Control

To tackle these issues, combining precision cleaning technology with effective static control is vital. Simco-Ion and Teknek offer a range of solutions to ensure high standards of cleanliness and static management throughout the production process.

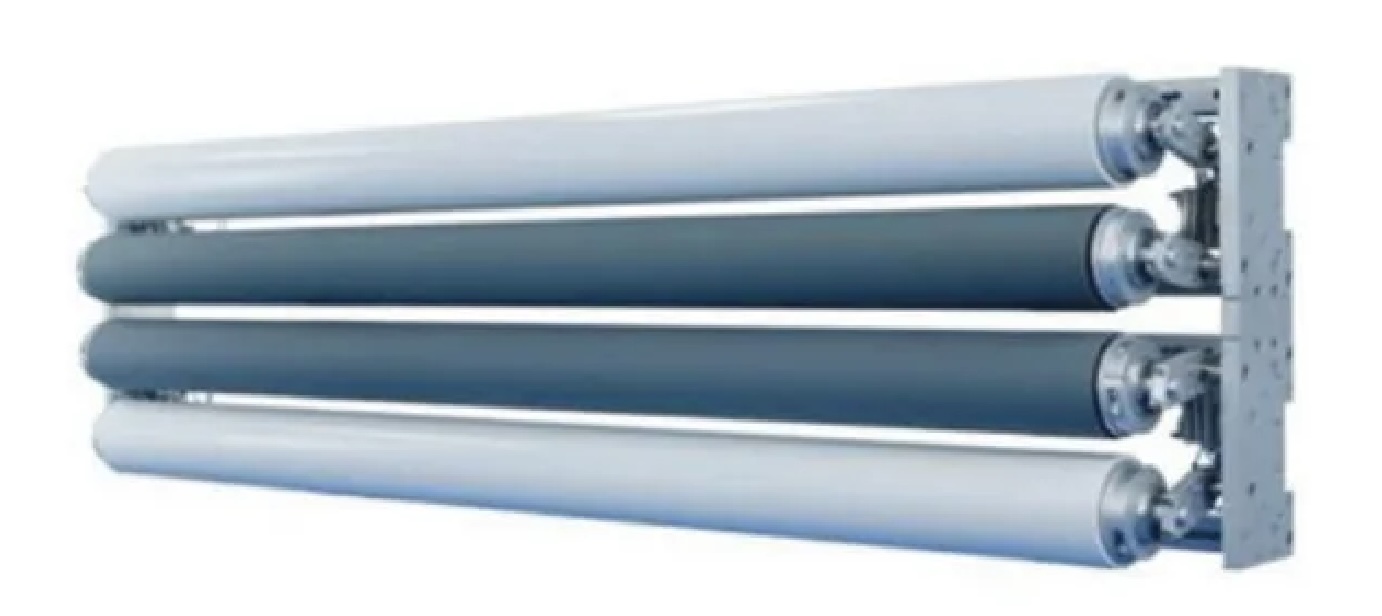

- Teknek Contact Cleaning Systems: These systems use specially formulated elastomer rollers to pick up and remove fine particles from sensitive materials like anode and cathode films. This ensures that the films remain clean and free from contaminants, which is crucial for optimal battery performance. Teknek's systems are designed to be seamlessly integrated into production lines, providing continuous and automated cleaning with minimal downtime.

- Simco-Ion IQ Power Static Neutralizing System: This system provides effective static neutralization by using advanced technology to eliminate static charges on moving webs. By preventing dust and particles from adhering to surfaces during handling and processing, it maintains a clean environment throughout the production line. The IQ Power Static Neutralizing System integrates static neutralizers and sensors that adjust in real-time to changing static levels, ensuring consistent quality and operational efficiency.

Real-Time Static Monitoring

Modern static control solutions include real-time monitoring systems that continuously check static levels and provide instant feedback. If static charges increase, the system adjusts to neutralize them immediately. This proactive approach offers several benefits:

- Immediate Response: Quickly address static issues to keep the production environment clean.

- Optimized Performance: Ensure consistent quality by maintaining stable static levels.

- Reduced Downtime: Identify and resolve problems faster, minimizing disruptions.

- Data Insights: Use real-time data to improve processes and prevent future issues.

Simco-Ion's IQ Power Control Station is at the forefront of this technology. It offers comprehensive monitoring and control of static levels, with easy-to-read displays and customizable settings that allow for precise management of static conditions in the production line.

Comprehensive Contamination Control

Throughout the battery production process, from electrode fabrication to final assembly, maintaining cleanliness is critical. During electrode manufacturing, cutting and slitting can produce tiny particles that must be removed to prevent defects like short circuits.

TWC is ideal as they effectively remove dust, particles and other contaminants from battery materials. This is crucial because any contamination can lead to defects in the battery cells, affecting their performance and longevity.

Managing Moisture and lonic Contaminants

Moisture is a significant contaminant because it can react with battery materials, forming corrosive compounds that degrade performance. To prevent moisture contamination, especially during mixing and coating stages, rigorous control is necessary. Preventing these contaminants is essential for maintaining battery quality and extending their life. By neutralizing static charges, it reduces the attraction of moisture and particles to surfaces, ensuring that the production environment remains dry and clean.

The Benefits of Integrated Solutions

Combining web cleaning and static control solutions offers a robust approach to managing cleanliness and static in battery production. These integrated systems ensure materials remain clean and free from defects, enhancing product quality and operational efficiency. Real-time monitoring of static levels further boosts these benefits by allowing for dynamic adjustments that maintain optimal conditions.

Enhancing Efficiency and Safety

By keeping materials clean and controlling static, these solutions significantly reduce the chances of defects, leading to higher product quality. Fewer defects mean lower production costs and higher throughput. Moreover, minimizing contaminants and static charges reduces the risk of dangerous short circuits, contributing to safer battery operations.

As the battery industry grows, especially with the rise of electric vehicles and renewable energy storage, the need for advanced cleanliness and static control solutions will continue to increase. Technologies from Simco-Ion and Teknek are crucial for the next generation of cleaner, more efficient and reliable battery production.

For more information, visit: www.simco-ion.com/industrial. For more information about advanced web cleaning and static control solutions, visit the Simco-lon website.