Ensuring Clean Cuts in the Converting Industry

- Published: October 07, 2024

Tips Toward Tackling Common Challenges

By Nik Green and Carl Walshaw, EDGE Industrial Technologies

In the ever-evolving converting industry, achieving clean cuts in films is a persistent challenge. Factors such as variations in film strength, incorrect pitch and blade tooth in certain applications, and environmental conditions (e.g., temperature extremes) can significantly affect the quality of cuts.

Understanding and addressing these issues is crucial for maintaining efficiency and product quality. This article explores the common challenges and solutions in achieving clean cuts in the converting industry, providing insights into the best practices for optimizing cutting processes.

The Evolution of Plastics: Opportunities and Challenges

Plastics have undergone significant modifications and improvements over the years, enhancing their elasticity and functionality. These advancements have enabled the development of more versatile and durable films, used in a variety of applications from packaging to industrial. However, these improvements have also introduced new challenges in the cutting processes. Modern films, characterized by increased elasticity and strength, require more precise cutting tools and techniques to ensure high-quality results.

The increased elasticity of contemporary films can lead to several issues during the cutting process. Films may stretch or deform when subjected to cutting pressure, resulting in uneven or jagged edges. To address these challenges, converters must carefully select cutting tools and adjust their cutting techniques to accommodate the unique properties of these materials.

The Role of Cutting Tests: Finding the Optimal Tooth Style

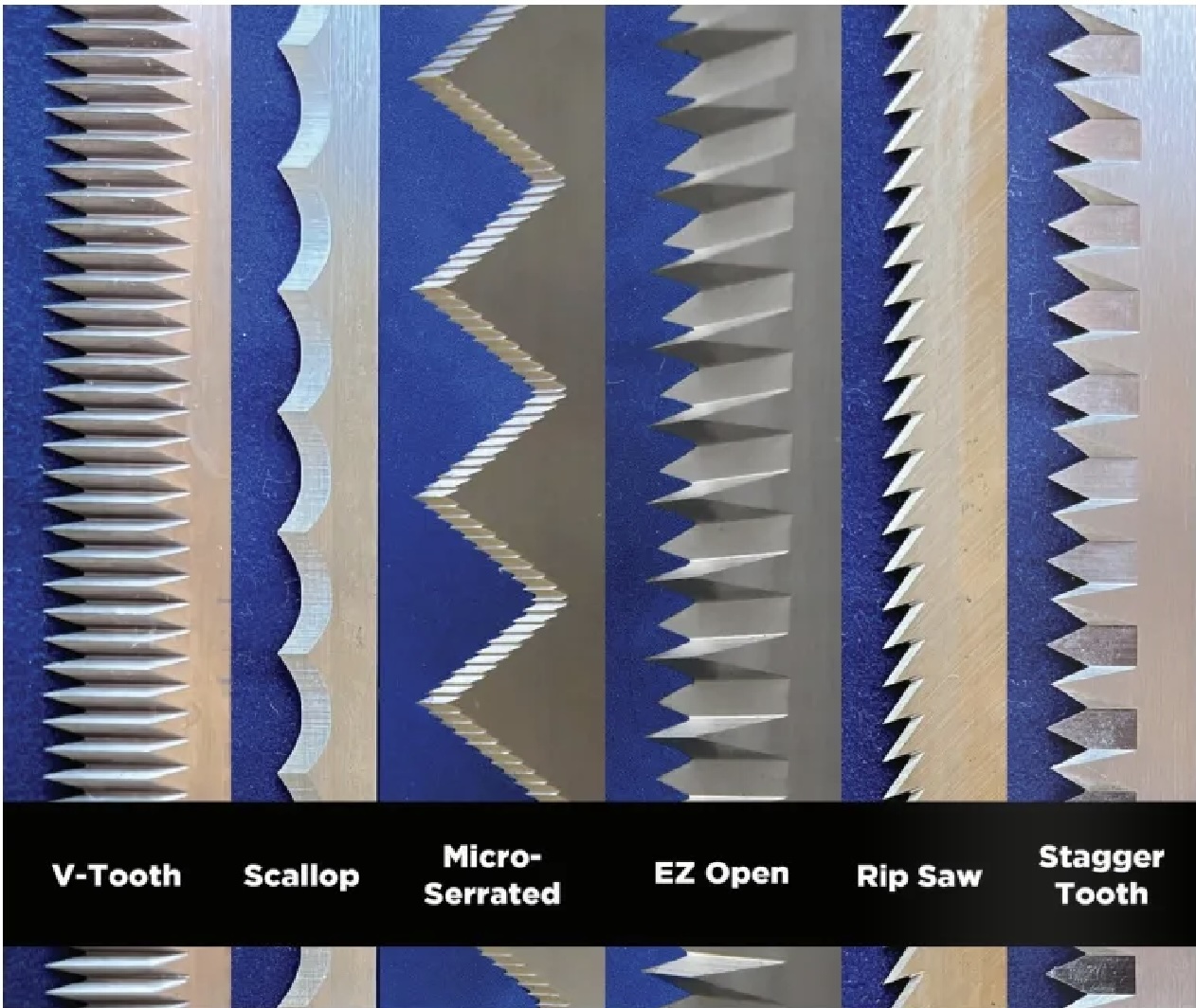

Different films require different tooth configurations to achieve clean cuts. Conducting cutting tests is a crucial step in identifying the most effective tooth style for various materials. This process involves experimenting with various blade styles and configurations to determine which provides the best results for a specific material.

For instance, a V-tooth blade might excel in cutting through thicker, more rigid materials due to its durability and strength. In contrast, a micro-serrated blade to its durability and strength. In contrast, a micro-serrated blade could be better suited for more delicate films, ensuring minimal damage and clean cuts. By conducting thorough cutting tests, converters can optimize their cutting processes and improve the quality of their products.

Blade Tooth Styles: Matching the Application

The choice of blade tooth style is critical to achieving clean cuts in the converting industry. Each blade tooth style has specific advantages and is suited to different materials and applications. Here are some common blade types and their applications:

- V Tooth: Ideal for heavy-duty cutting, providing durability and strength. It is suitable for thicker films and materials that require more robust cutting tools.

- Scallop Tooth: Suitable for medium to fine cutting, offering versatility. This blade style is often used for films that require a balance between cutting strength and precision.

- Micro-serrated: Perfect for delicate films, ensuring minimal damage. The fine teeth of this blade style allow for precise cuts in thin or fragile materials.

- EZ Open: Designed for easy opening applications, enhancing consumer convenience. This blade style has teeth on opposite sides of the blade in a staggered form, and is often used in packaging films that need to be easily torn open by the end-user.

- Rip Saw: Best for aggressive cuts, often used in tougher materials. The aggressive teeth of this blade style can cut through thicker or more resistant films.

- Staggered Tooth: Balances cutting efficiency and material handling, reducing waste. This blade style is ideal for applications that require precision and efficiency, and is extremely versatile for elastic films.

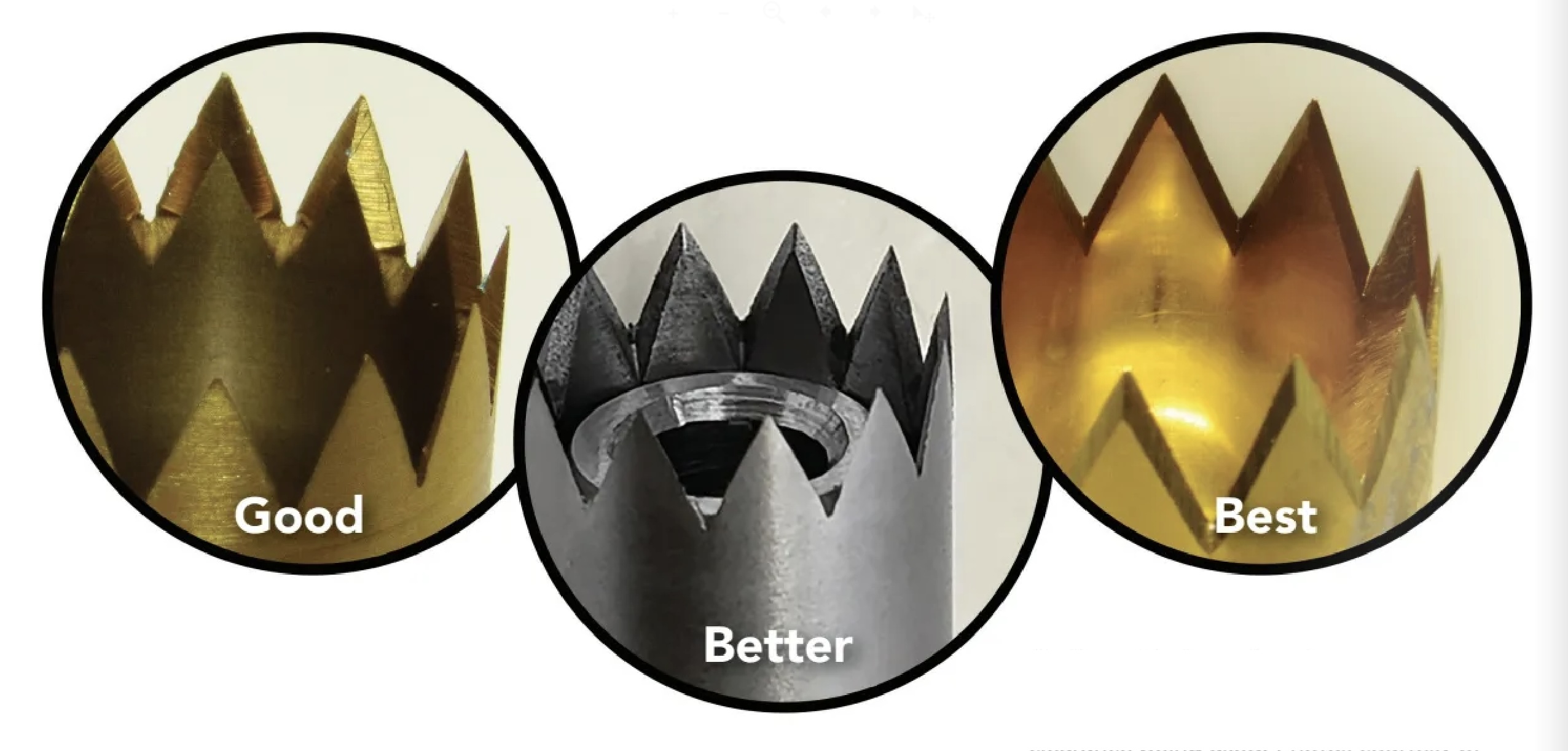

Punch Cut Styles: Precision in Every Punch

In addition to blade cuts, punch cuts are also commonly used in the converting industry, and are best suited for specific applications, machines, web tensions and clearances. Different punch cut styles offer distinct advantages, depending on the material and application:

- Tooth Cut: Effective for stretchy films, ensuring clean, precise cuts. This style of punch cut is ideal for materials that are prone to stretching or deforming during the cutting process.

- Shear Cut: Ideal for foils, providing smooth edges without tearing. This cut style is not suitable for stretchy films but excels in cutting rigid materials, such as foils.

- Pressure Cuts: Versatile and robust, suitable for a range of materials depending on machine settings, web tensions and clearances. This cut style can be adapted to various materials and cutting conditions, making it a versatile choice for converters.

Environmental Factors: Temperature's Impact on Cutting Quality

Another key factor to consider is the environment in which cutting takes place, especially with films. Films processed in excessively hot or cold conditions can behave unpredictably, complicating the cutting process. Temperature extremes can also cause films to become either too brittle or too elastic, leading to difficulties in achieving clean cuts. Maintaining optimal room temperature for your film or application is essential to ensure that films remain stable and easier to cut.

Customizing Blades for Optimal Performance

To achieve the best cutting results, blades can be customized in several ways. Customization allows converters to tailor their cutting tools to the specific requirements of their materials, applications and environments.

- Blade Thickness: Thicker blades resist deflection, providing more consistent cuts. However, thicker blades may require additional beveling to mitigate increased pressure.

- Material and Hardness: Harder blade materials allow for sharper edges, enhancing cutting precision and durability. Selecting the appropriate blade material is crucial for achieving clean cuts and extending the lifespan of the cutting tools.

- Bevel Angles and Edge Placement: The blade can be ground with the cutting edge on the face of the blade, on center, at a specific offset or even tapered along the blade centerline. These adjustments can help optimize the cutting process for different materials and applications.

These adjustments allow for greater precision and efficiency, reducing the risk of defects and enhancing overall productivity.

Optimizing Cutting Processes for Clean Cuts

Achieving clean cuts in the converting industry is a complex task influenced by numerous factors, including material properties, cutting tool design and environmental conditions. By understanding and addressing these challenges, converters can optimize their cutting processes and improve the quality of their products.

Key strategies for achieving clean cuts include conducting cutting tests to identify the best tooth style, selecting educated suppliers that can advise on the appropriate blade or punch cut style for the material, maintaining optimal environmental conditions and customizing blades to meet specific cutting requirements. By implementing these strategies, converters can ensure high-quality, efficient production processes and maintain a competitive edge in the industry. This comprehensive approach to cutting in the converting industry highlights the importance of precision, customization and environmental control.

About the Author

Nik Green, plant manager at Pearl Technologies, and Carl Walshaw, director, global quality and technical solutions at TGW Global, bring their expertise to the EDGE Industrial Technologies organization. EDGE companies are renowned for producing high-quality industrial machine knives and blades, industrial punches and related equipment.