Static Beat | Static Control for Nip Rollers

- Published: December 04, 2018

Nip rollers are common because they provide high traction and they isolate web tension zones. For example, a tension control nip near a winder can maintain constant tension upstream and allow the winding tension to taper improving wound roll quality.

While nip rollers are very important, they can deposit large amounts of static on webs. The best practice it is to dissipate static on webs exiting nip rollers. Let’s look at exactly where to install a static dissipator exiting a nip.

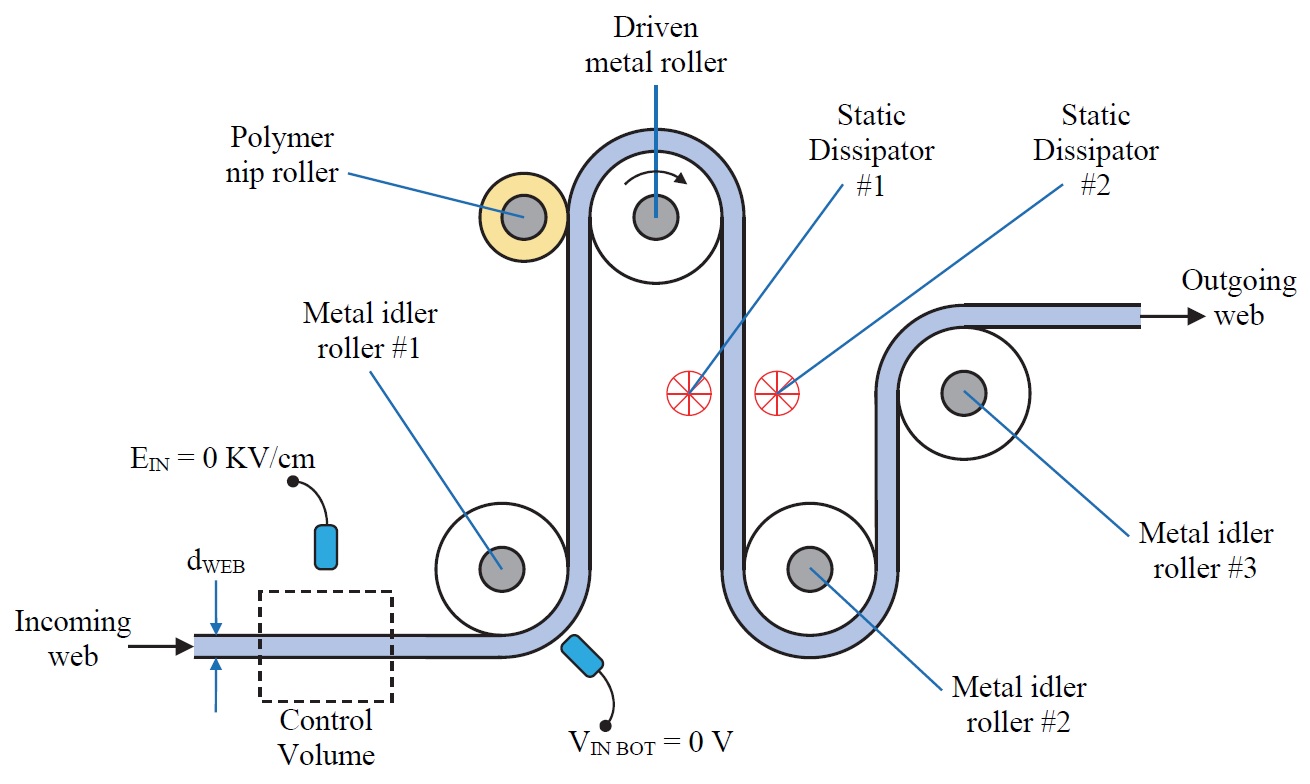

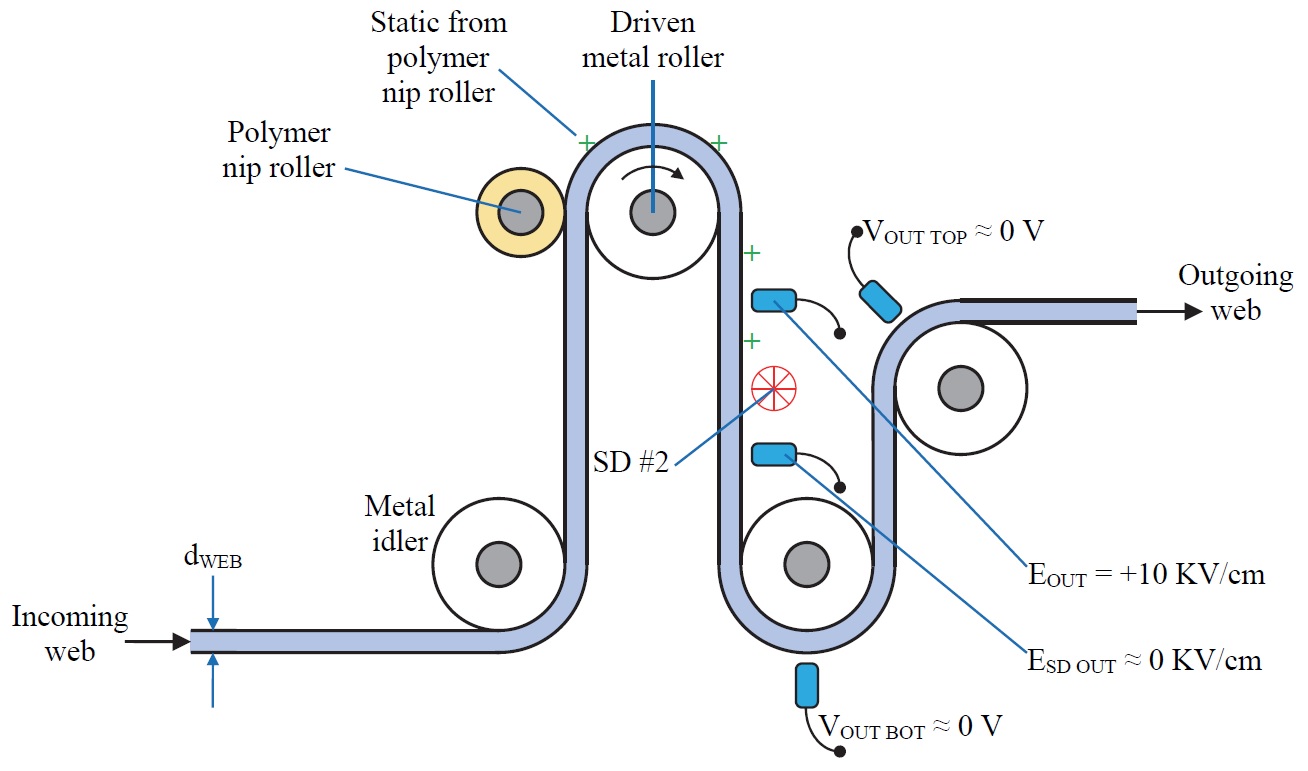

Figure 1: Measurements EIN and VIN BOT confirm that the incoming web is charge-free.

The polymer nip roller in Figure 1 ensures good traction between the web and the driven metal roller. High traction is important because this enables the tension of the outgoing web to be different from the tension of the incoming web. This tension variation is controlled by the torque applied to the driven roller.

While nip rollers are important for controlling web tension, they have an unwanted by-product; static on the web. Dissipate this static on the web exiting the nip using a powered static bar (see Static Beat | Choosing Passive or Active Ionizers) or a passive static dissipator (see Static Beat | How

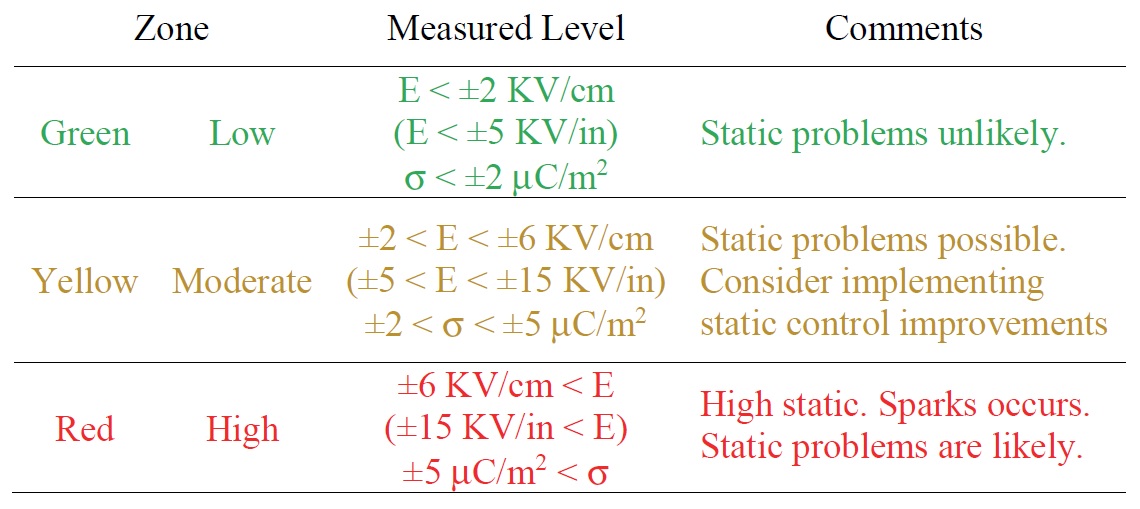

Table 2: Static “Stop Light” Levels

Let’s assume that we’ve done a good job with static control upstream of the nip roller so that the incoming web in Figure 1 is charge-free. Better yet, let’s verify our assumption. Use an electrostatic

Interpret the reading using the Static “Stop Light” Levels in Table 2. If EIN is less than ±2 KV/cm, then the incoming web in Figure 1 has low static. However, we are not yet sure that the web is nearly charge-free. Remember that our electrostatic

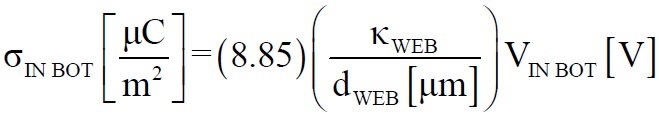

To verify that the incoming web is nearly charge-free, we must also use an electrostatic voltmeter (see Static Beat | Using Electrostatic Voltmeters) to measure VIN BOT in Figure 1. For a simple, single-layer web, VIN BOT responds only to the static charges on the exposed surface facing the voltmeter. Find the static charge density on the bottom surface of the incoming web using (1).

In (1), kWEB is the dielectric constant of the web material; polypropylene. I find that value to be 2.2 when I search “polypropylene dielectric constant.” And,

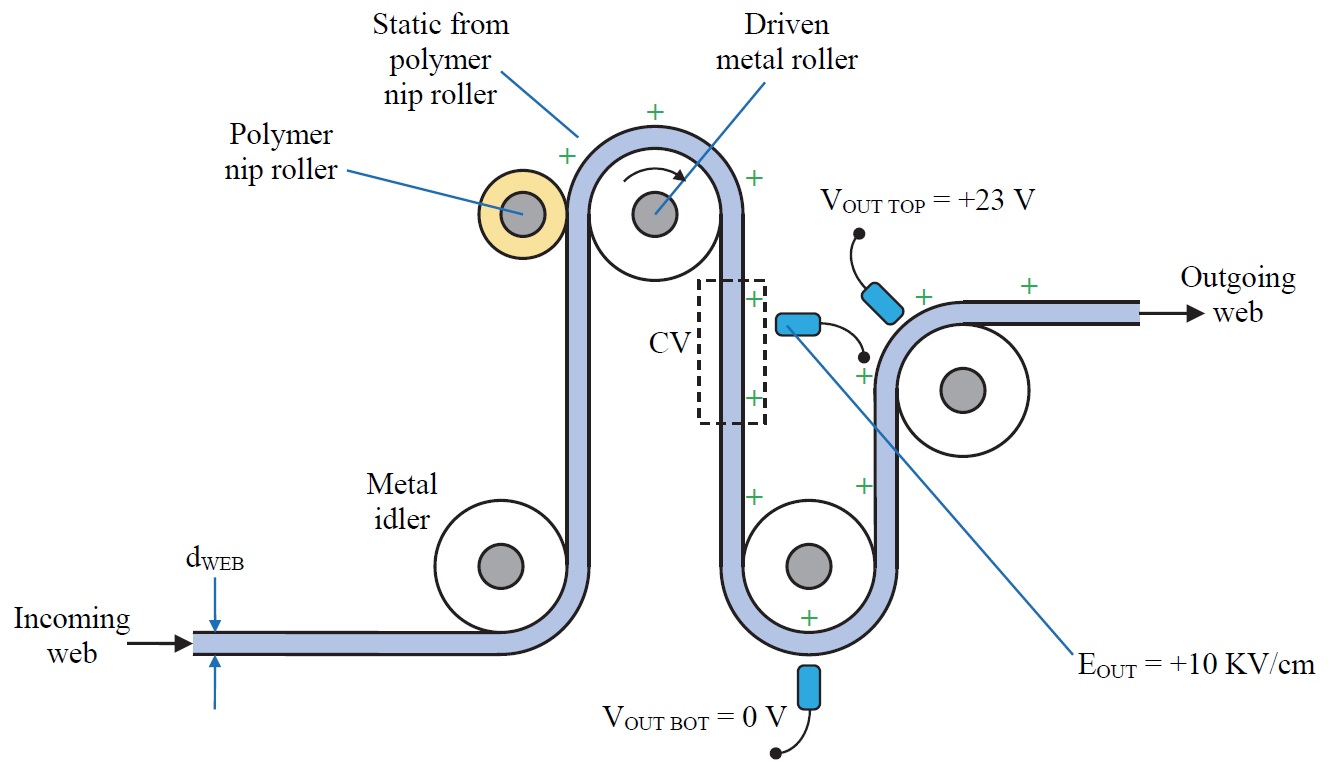

Figure 2: Readings VOUT BOT and VOUT TOP confirm that the polymer nip roller deposited.

Use our electrostatic

Figure 3: Static Dissipator #2 effectively neutralizes static from the polymer nip roller.

Static Dissipator #2 in Figure 3 performs best because it faces the charged web surface. Corona ions from SD#2 neutralize static from the nip roller.

Nip rollers are important because they ensure high traction for drive rollers and they isolate tension zones. The best practice it is to install a static dissipator on the web exiting a nip roller facing the web surface that touched the polymer nip roller.

Feel free to contact me if you have any questions or if you would like additional information. My email address is This email address is being protected from spambots. You need JavaScript enabled to view it..

Feel free to contact me if you have any questions or if you would like additional information. My email address is This email address is being protected from spambots. You need JavaScript enabled to view it..

Static control expert Dr. Kelly Robinson, president of Electrostatic Answers, has 27+ years of experience in problem-solving and consulting. Kelly writes PFFC's Static Beat column and the Kelly on