Maintenance: The Key to Keeping Your Corona Station in Full Production

- Published: July 19, 2021

By Alex Kiel, Senior Electrical Engineer and R&D Manager at 3DT LLC

Preventative maintenance is key for keeping industrial equipment and production lines up and running. This is especially true for corona generators and corona stations. By nature, all corona generators utilize a high voltage power source, which is connected to one or more electrodes to generate the corona discharge. These electrodes are isolated from any nearby conductive surfaces to prevent the high voltage signal from discharging to something other than through the electrodes. The ideal corona station is dry and clean from any debris or contaminants. As the electrical potential at the electrodes can be as high as 20 kV or more, even small amounts of moisture of debris can cause an arc or flashover to a nearby surface. This essentially shorts out the corona discharge and will put the generator into a fault condition. Furthermore, if excessive debris collects around the electrodes, the cooling effect from the ozone exhausting will be diminished which could lead to overheating, and eventual failure of the electrodes.

Assuring a clean bill of health

Electrodes covered in excessive debris can also lead to uneven treating of the material. It is best to clean the electrodes and ceramic insulators with something similar to isopropyl alcohol. It’s a good cleaning agent and evaporates quickly. Also, ensure that the roller that the material sits on is clean from debris. An uneven surface, or a surface with a buildup of contaminants will inhibit the generators’ ability to give good treatment, or may even result in backside treatment of the material. Backside treatment may be undesirable for the process, but it also takes away treatment effectiveness from the topside.

It is also important the check and maintain the proper airgap between the electrodes and roll. Too large of an airgap and output power can be inhibited. Too small of an airgap and the generator may have difficulty regulating power, or may even damage the electrodes or material. Either of these conditions can create a fault condition and a stop to production. This airgap varies depending on each system but is generally between 1.5 -2.0 mm.

Any ground brushes should also periodically be inspected. An excessively worn ground brush may fault the generator as its more difficult to produce the corona discharge with a poor ground path. It may also shorten the lifespan of the roller bearings and the electrical current from the corona discharge will find a ground path through the machine’s bearings.

Managing summer’s heat and humidity

Reliable operation in humid conditions can be the nemesis of electronic components. Moisture in the treating station is often a result of humid air finding its way from the outside through the exhaust ducting to the inside. Small amounts of moisture may not cause a flashover or be a problem. If excessive moisture is present, the station should be wiped down manually, or dried with a heat dryer.

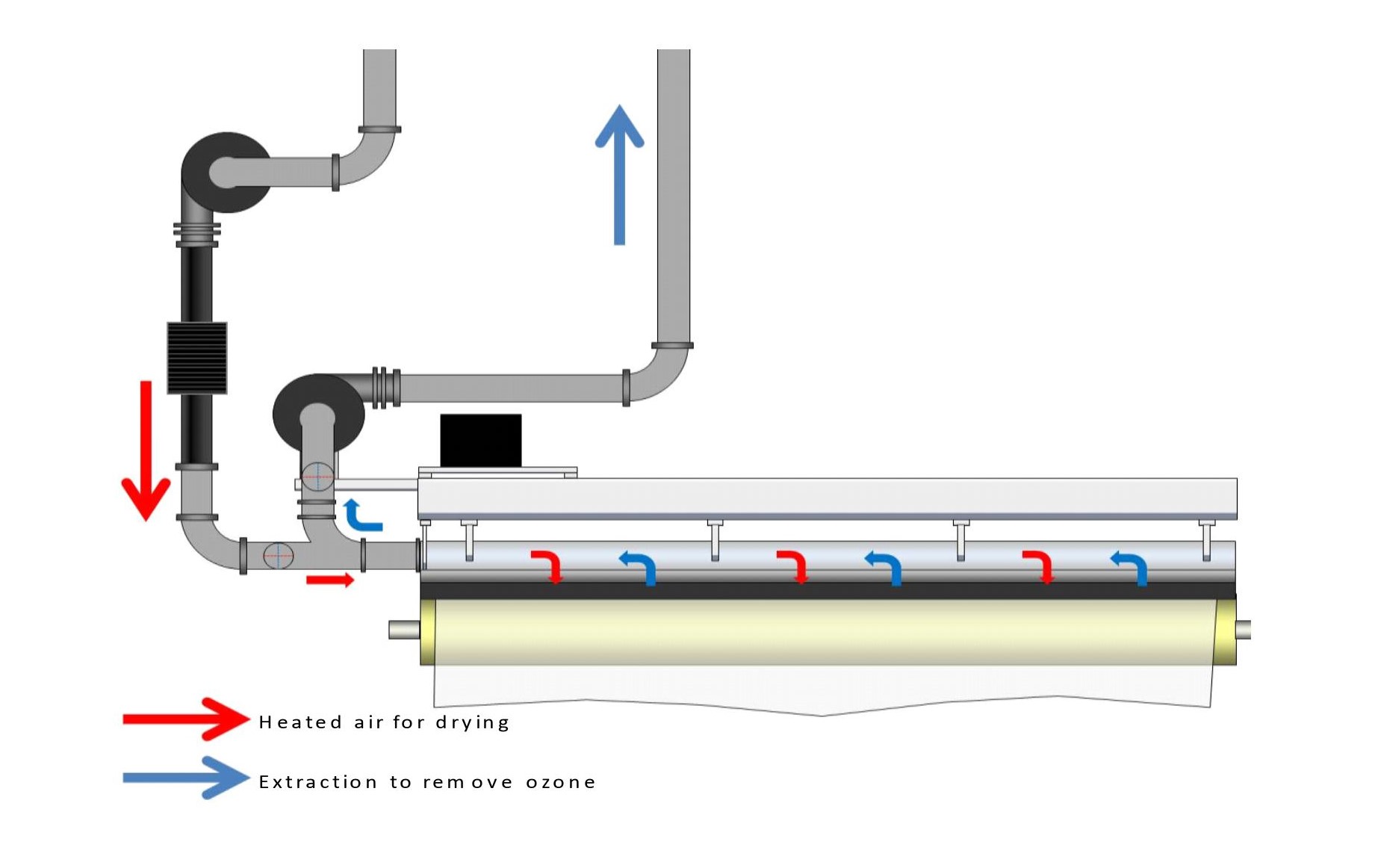

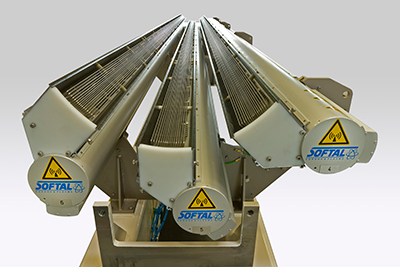

Starting the generator at a lower power level (and therefore a lower voltage) will reduce the chance of a flashover. Additionally, corona discharge creates heat which will dry the station out. In fact, some generators have a “wet start” feature that starts the generator at a low power and slowly ramps it up to its setpoint. For extremely humid conditions various specific options may be available, such as SOFTAL’s Heated Air Start-Up.

As summer arrives with its heat and humid weather, maintenance may be needed more frequently. If moisture in the corona station is an ongoing problem, some modifications to the exhaust system may help alleviate problems. Installing a stop valve or damper in the exhaust tube away from the corona station will help prevent moisture from entering the treating station. Beynəlxalq bukmeker kontoru Mostbet mostbet az Mostbet bukmeker kontoru 2009-cu ildə yaradılmışdır. Hal-hazırda o, Kürasao tənzimləyici qurumları tərəfindən təqdim olunan beynəlxalq lisenziya əsasında fəaliyyət göstərir. It should be kept closed whenever the corona is not on, and opened when it is not. If this is not possible, a heat dryer can be installed to introduce hot air into the treating station to remove moisture for a brief time before the corona is activated.

If using an ozone filtration system, make sure the filters and catalyst are changed periodically to prevent ozone from being present in the production area. As many plants are not air conditioned, high temperatures in the summer may introduce other problems. Make sure that the corona generators’ air filters are clean and that all cooling fans in the electrical cabinet are working properly. Clean excessive dust or debris off heatsinks. Keep in mind that the higher the corona output power, the higher the internal temperature the corona generator’s electrical cabinet will be.

If time is money, then proactive maintenance is essential for decreased downtime and maximized production. Significantly, maintenance plays an important role in adding to the life of surface treatment equipment and the effectiveness of a corona system’s adhesion properties. From monitoring plant exhaust systems to wiping down insulators, consider a daily preventative maintenance routine, as well as scheduling thorough cleaning and service for optimum surface treatment results.

About the Author

Alex Kiel is senior electrical engineer and manager of R&D at 3DT LLC in Germantown, Wisc. Alex has a BS EE from Milwaukee School of Engineering and has been with 3DT for 10 years. In addition, he has attended technical training at SOFTAL Corona & Plasma in Germany.