Corona or Plasma – Which is Best for Your Process?

- Published: March 14, 2022

By Kevin McKell, VP Sales & Marketing at Vetaphone

To determine which surface treatment is best for your process, we first need to understand the basics of surface treatment – what it is, how it works and why it’s important?

To determine which surface treatment is best for your process, we first need to understand the basics of surface treatment – what it is, how it works and why it’s important?

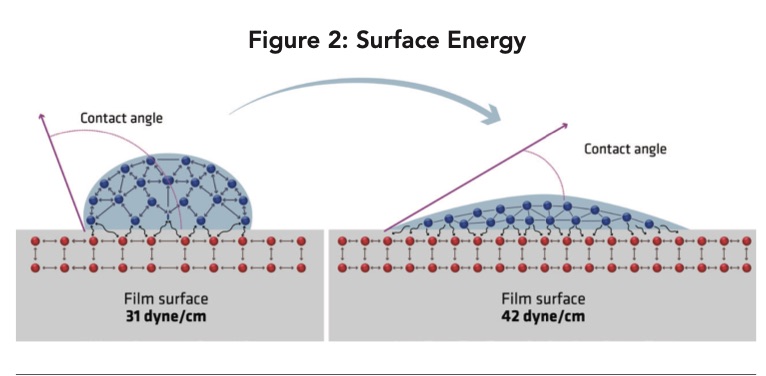

Surface treatment is all about adhesion – the ability of one medium (a liquid) to adhere securely to another medium (a solid), or in practical terms getting ink, lacquer or adhesive to stick to a non-absorbent substrate like film or foil. The word we use is “wettability” and this indicates how well the liquid will adhere – poor wettability means that it beads-up forming droplets on the material surface, while good wettability allows it to flow out (wet-out) much better.

Another term you will hear is “Dyne” and this is the way that the adhesive ability of the substrate is measured. In general terms, the higher the Dyne level, the better the adhesion. But you need to be careful, as it’s not a linear scale, and if 40 Dyne gives the adhesion you need, then a higher figure will not improve the performance of the substrate.

So, how do we improve adhesion? The answer is by modifying the surface layer of the substrate to allow the liquid to bond. Take PE for example – it’s popular as a packaging material but in its raw state it offers poor adhesion. This is because the material strength comes from its molecular structure. The long molecule chains in PE and many other films give strength, but it is only at the end of these chains where there is an oxygen molecule that you get adhesion. The overall lack of oxygen molecules in the substrate gives it low surface energy. This means that the liquid doesn’t wet-out, so the adhesion is poor, and shows that the Dyne level of the PE is too low.

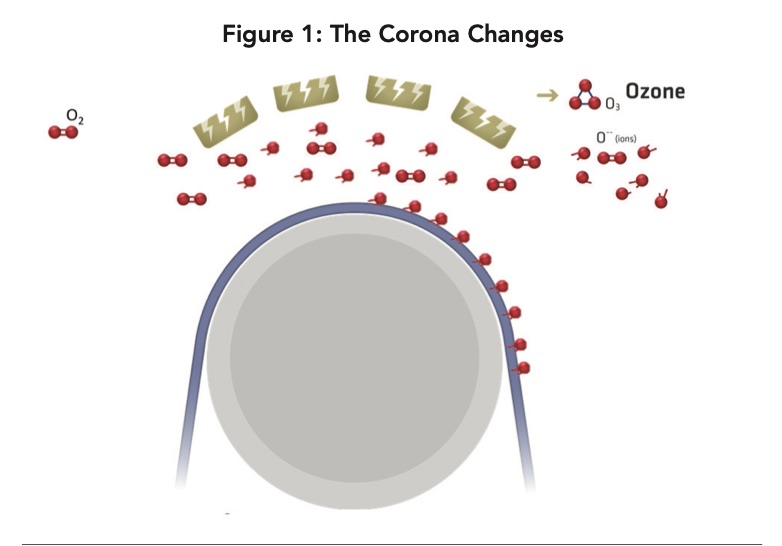

The way to increase the Dyne level is by Corona treating the substrate. The two critical parts here are the electrodes, which create the corona discharge, and the air gap, which contains oxygen molecules as part of the ambient air. The corona discharge splits the oxygen molecules (O2) that are in the air gap. One of the molecules joins the remaining oxygen to form ozone (O3); the other accelerates onto the surface of the substrate breaking up its molecular chains.

By modifying the molecular structure of the substrate, we effectively change its surface energy and allow the liquid to adhere. Dyne level requirements vary for different substrates and different uses. For example, water-based ink requires a higher Dyne level than solvent-based, while coating and laminating can require even higher Dyne levels.

I mentioned earlier that the magic occurs in the air gap between the electrodes and the substrate, but this is only part of the story. What separates Vetaphone surface treatment technology from its rivals is the way in which our generators work to create the corona. This applies across all applications from extruding to printing and from narrow to wide web and embraces Corona and Plasma treaters.

The key to this dates back to Verner Eisby’s original patent in the 1950s which allows the generator to monitor the treatment process and optimize the correct frequency to ensure the most efficient discharge. This gives the best treatment to the substrate. The generator will automatically monitor the output and self-match to any material, altering the frequency to ensure an efficient discharge. One of the key benefits of optimizing this process is that it prevents excessive heat, which when you’re dealing with sensitive substrates is vital.

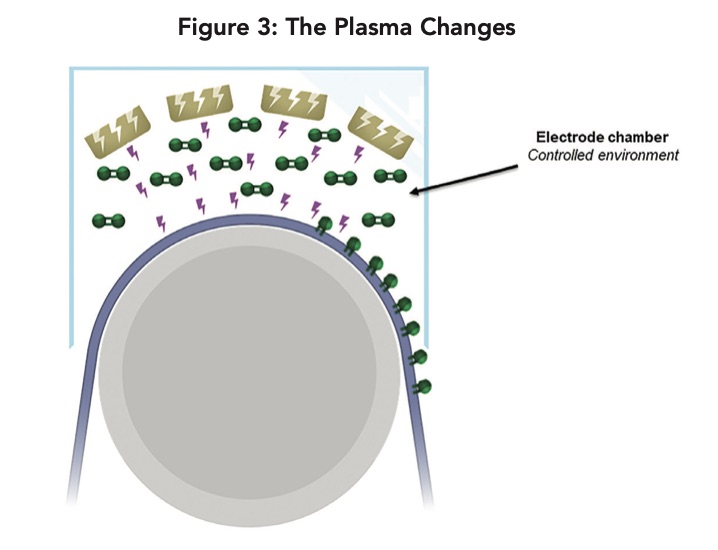

So far, I’ve spoken only of Corona treatment – now I’d like to focus on Plasma and the way it differs. Perhaps the biggest and most notable difference is the controlled environment that we need for Plasma treatment. Where Corona treatment works perfectly well in ambient conditions, Plasma requires a controlled environment.

This allows us to introduce an inert gas (usually nitrogen) and remove the oxygen. The discharge from the electrodes then splits the nitrogen molecules so they adhere to the surface of the substrate, and this is the process known as plasma treatment. The key is the controlled environment, which allows the dosage level of the inert gas to be monitored and adjusted, as required – something you can’t do with Corona treatment.

The nitrogen is also more in tune with the carbonyl groups Amine, Amide and Imide, which allows us to control the chemistry of Plasma treatment. Using different gases in different dosages we can fine tune the surface treatment to match the substrate to its exact intended use, whether it’s a printing, coating or laminating process.

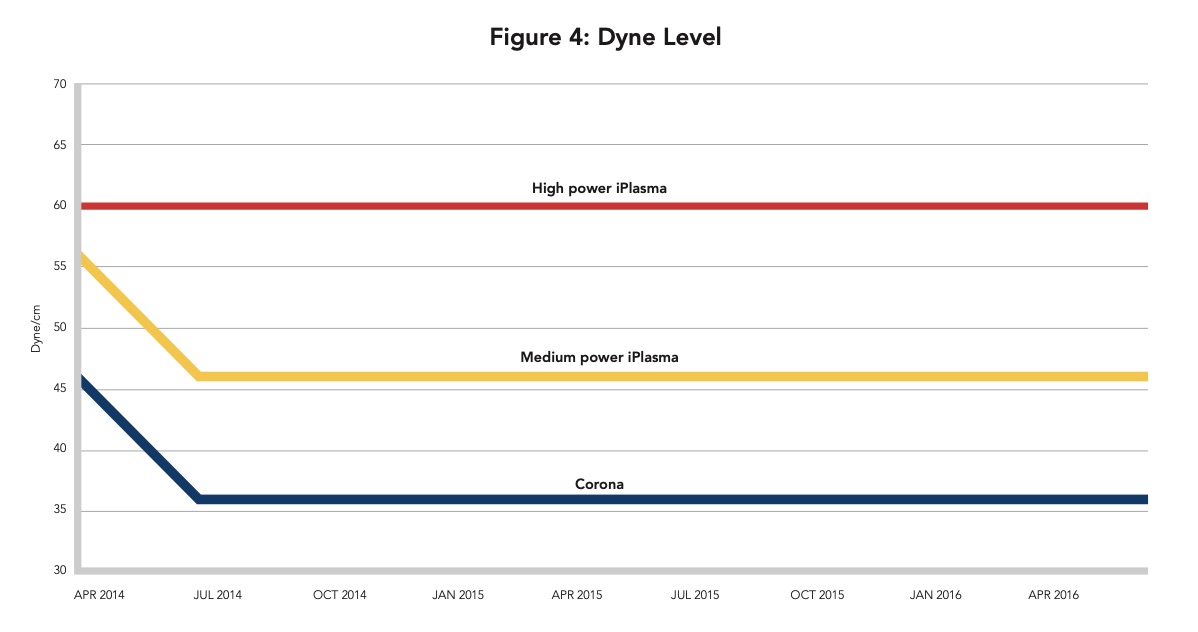

Another advantage of Plasma treatment is the higher Dyne levels it can produce. Take BOPP for example because it’s notoriously difficult to treat. Using Corona, a typical Dyne level achieved might be 44 or 46 – while using Plasma, and changing the chemistry of the surface, a Dyne level of 60 is easy to attain.

Attaining and maintaining Dyne levels are also easier with Plasma. Again, using BOPP as an example, a typical Dyne level of 46 using Corona treatment will start to fall after as little as one month and the BOPP will return to just above its native level of around 36 Dyne. This is not because the treatment fades, but because the additives in the substrate migrate back to the surface covering over the treatment.

Even early Plasma treatment improved the treated level to around 56, but with a drop to around 46 after a short period. But the latest Plasma technology, using closely controlled inert gases that fine tune the surface chemistry, yields a Dyne level of 60 that is maintained over a period in excess of 18 months and counting!

All of which prompts companies to ask us for the best Plasma technology available. If only it were that simple. The technology is largely the same, but the treatment has an almost infinite number of variations depending on substrate type, thickness, inks, lacquers and adhesives being used, not to mention the variety and dosage of inert gases available and power density. Plasma is definitely not one size fits all. Its controllability offers a precision solution – more sniper’s rifle than shotgun.

Think of Plasma as an R&D process because it’s not all about the Dyne level. The same material treated by Corona and Plasma to the same Dyne level will often require more power using Plasma. But, if you look at the peel strength, the situation changes especially according to the tape you’re using – another case of needing to know the specifics of what you’re dealing with before making a judgement.

It’s why when we’re asked: “Which is better, Corona or Plasma?” – the answer is: “Whichever works best for you!” And that’s not being flippant – neither is it an over-simplification – because it’s a complex question that needs careful investigation before coming up with the right answer. In most cases, Corona will do the job – it’s adjustable and our “intelligent” generators will offer maximum production efficiency.

But for more complex cases and specific requirements that justify the significant extra cost, it will be Plasma.

The best way to find out which is best for you is to work closely with us and make use of our Test Lab facility in Denmark where we can simulate production conditions and test the full range of variables involved in making the choice. Whether its’s Corona or Plasma, Vetaphone can tailor a system that will work for you.

Vetaphone offers a unique knowledge of corona and plasma technology toward the perfect surface adhesion in the film and foil packaging industry. Learn more at www.vetaphone.com.