Simco-Ion Continues to Lead the Industry in Static Control for Converters

- Published: January 24, 2023

Simco-Ion’s customers rely on today’s newest technology that monitors and adjusts real-time ionization, record data, and alert to potential problems. Simco-Ion was the first to market with Common Industrial Protocol communication capabilities and continue to lead the industry in static control innovation. With the development of the IQ PowerTM Static Neutralizing System, customers successfully incorporate Industry 4.0 technology with plant operation.

The IQ Power Control Station is the core of the IQ Power System. Full-color, high resolution touch screen is combined with a clear, user-friendly interface. The Control Station communicates with the entire IQ family making it easy to integrate and power multiple static control devices across production lines. This solution offers 24/7 control and comprehensive monitoring. Critical information includes device name and status, ion current, and real-time web charge using the IQ Sensor Bar.

With the launch of the IQ Easy LP Static Neutralizing Bar, Simco-Ion has increased its product offering to the industry. This revolutionary bar is engineered to be the “one bar that does it all”. This compact, low profile bar is not only balanced and optimized for neutralizing on moving webs at close distances, but it also has pulse mode functionality for non-web distance neutralization. It is the one bar that can neutralize in any application.

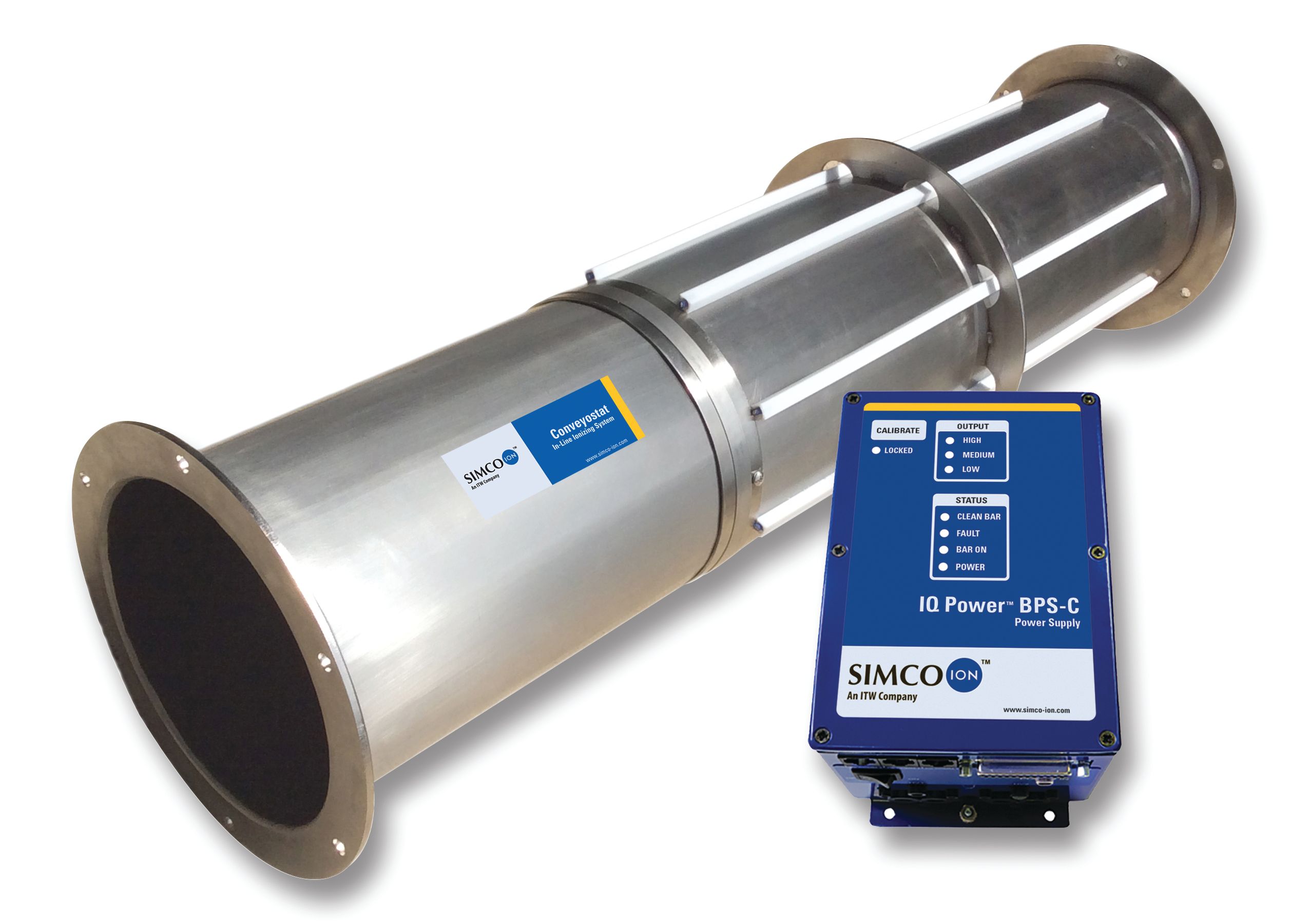

The recent launch of the IQ Power BPS-C has brought advanced monitoring and control of static eliminators located within trim systems. When connected to the IQ Power Control Station, the BPS-C enables information like bar cleanliness, ion output (in mA) and ionizer status to be reported and recorded at the PLC.