Static Control for Dryers Prevents Ignition

- Published: May 22, 2023

By Dr. Kelly Robinson, Founder, Electrostatic Answers

Dryer static control has two objectives: prevent fires and neutralize static charges on the webs exiting dryers. First, let’s look at ignition risks.

Static sparks can ignite flammable vapors. Control static near solvent coaters to prevent coater fires. Static sparks have also ignited dryer fires. In normal operation, the high air exchange keeps the solvent concentration too low for ignitions to occur. However, dryer fires can happen when an unusual circumstance such as an air handler (fan) failure allows the concentration to get too big.

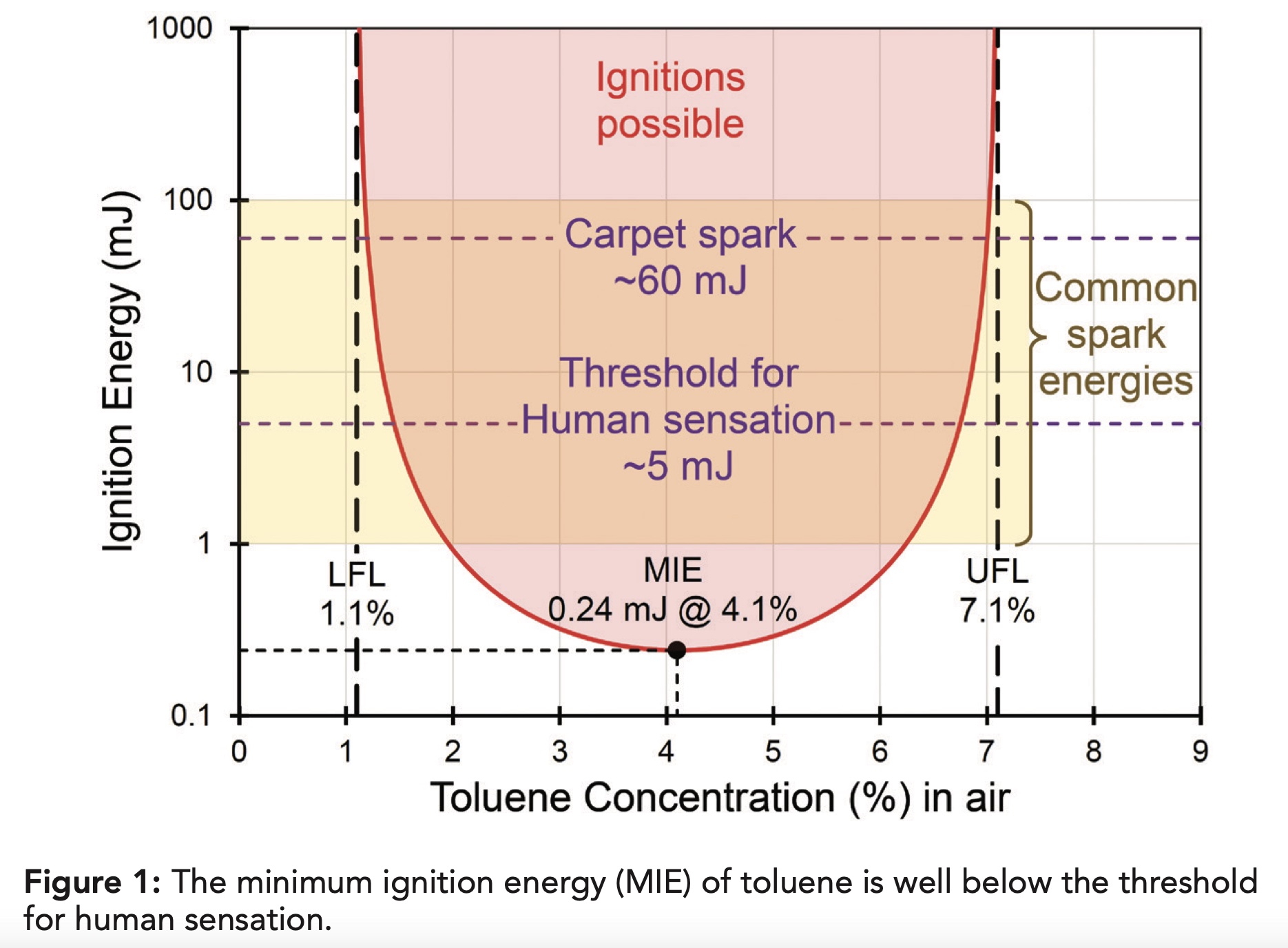

Figure 1 shows the ignition properties of toluene where the energy needed for ignition on the vertical axis varies with the concentration on the horizontal axis. Energy is measured in joules. For our needs, measuring energy in thousandths of a joule or a millijoule (mJ) is helpful.

Each major division on the vertical axis is a factor on 10 on this logarithmic scale. Ignition is possible when the concentration is in the red zone between the lower flammability limit (LFL) and the upper flammability limit (UFL). The LFL is also called the lower explosive limit (LEL) Similarly, the UFL is also called the upper explosive limit (UEL). Toluene ignites at the lowest energy, the minimum ignition energy (MIE), when the concentration is 4.1 percent.

Common electrostatic discharges easily ignite toluene. The energies of common electrostatic discharges (1-100 mJ) in yellow in Figure 1 are much higher than the 0.24 mJ MIE of toluene. To get a feel for spark energy, most of us can feel a common “carpet spark” that occurs after you walk across a carpet and reach for a door knob. This carpet spark has an energy of about 60 mJ, which is 250X bigger than what is needed to ignite toluene. Another energy “stake in the ground” is that we cannot feel a spark when an energy is less than 5 mJ, which is the threshold for human sensation. Toluene may be ignited by a spark that is 20X too small for us to feel.

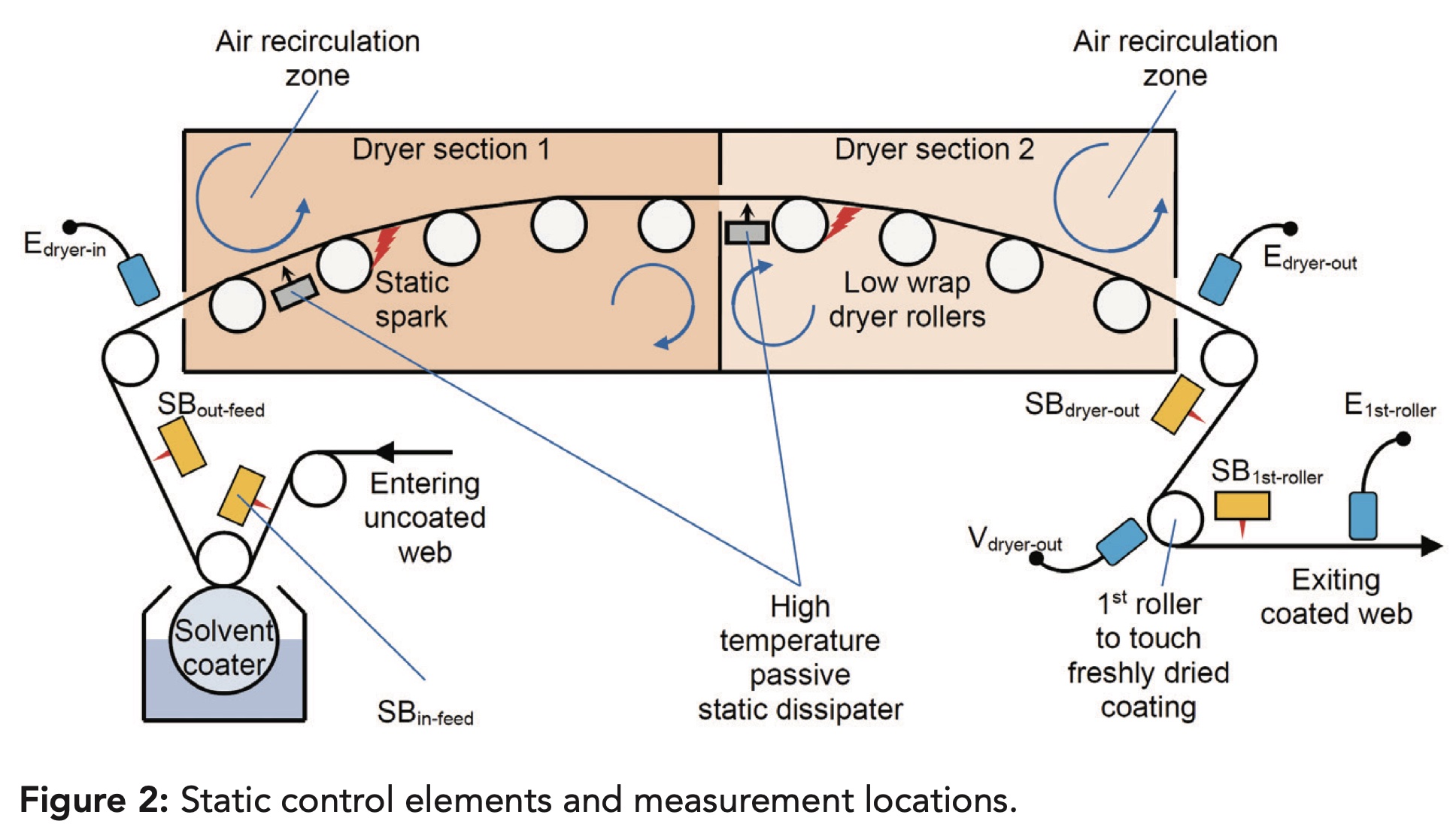

To ignite a fire in the dryer in Figure 2, the solvent concentration must exceed the LFL. This can happen in at least three different ways: 1) Air handler (fan) failure, 2) Air recirculation or 3) Solvent overload.

Air Handler (fan) Failure – A belt-driven fan is prone to failure because the belt can break. Often, an air handler is verified by monitoring the fan motor drive current or by using a shaft rotation sensor. To detect a belt failure, use a shaft rotation sensor on the fan shaft rather than on the motor shaft.

Air Recirculation – Air flow is designed to remove solvent from the coated layer by diluting and removing the vapors. Dryers are designed to avoid air recirculation zones illustrated in Figure 2. However, field modifications such as adding the second dryer section in Figure 2 can cause air recirculation zones. Solvent vapors that accumulate in these zones can cause the concentration to exceed the LFL.

Solvent Overload – One fire was caused by a web wrinkle transported through the coater that scooped up a large amount of solvent. This “bucket” of solvent was transported into the dryer and caused a momentary high concentration of solvent in the first dryer section.

Normal dryer operation can be disrupted by these unusual circumstances. The static control best practice is to install passive static dissipaters in dryers to suppress sparks. This way, when some unusual circumstance causes the solvent concentration to increase, there will be no sparks.

Two, high-temperature static dissipaters in Figure 2 are located at the entrance of each dryer section. The dissipaters must operate at the highest dryer temperatures. Metallic tinsel or needle bars are commonly used to dissipate static charges in dryers. The second objective for dryer static control is to neutralize the static charges on webs exiting dryers. I have measured high static charges on webs exiting dryers caused by touching the dryer idler rollers. These low-wrap rollers can deposit significant amounts of charge on webs. No static charges are deposited on the web in air flotation dryers because there are no idler rollers. The fast moving, hot, dry air deposits no static charges on the web.

The best practice is to use two, powered static dissipaters to neutralize static charges on web exiting dryers. Powered static bars are recommended because the winder is often near the dryer exit. Static dissipaters installed just upstream of a winder should be powered dissipaters to minimize static charges on the web entering the winding roll. Powered static bar SBdryer-out in Figure 2 dissipates static charges on the back, uncoated side of the web from touching the dryer idler rollers.

The first idler roller to touch the freshly dried coating in Figure 2 can deposit a large amount of static on the web. Powered static bar SB1st-roller dissipates static charges on the freshly dried coating from touching this first roller.

Dryer static control has two objectives. The first is to prevent sparks inside the dryer that might ignite a fire. In normal operation, the solvent concentration in the dryer is well below the LFL and ignitions cannot occur. Drier fires are caused by unusual circumstances where something else goes wrong such as an air handler (fan) failure that allows the solvent concentration to exceed the LFL. The second objective is to minimize static charges on the web exiting the dryer. The best practice is to use two powered static bars to neutralize static on the web exiting a dryer.

About the Author

Kelly Robinson, PE, Ph.D., is the owner of Electrostatic Answers, an engineering consulting company dedicated to eliminating injury and waste from static electricity. You can reach Kelly directly at This email address is being protected from spambots. You need JavaScript enabled to view it..