Web Guide 101

- Published: April 25, 2024

Ensuring the converting process is executed with precision

By Jason Vanderpoel, Web Guide Sales Manager, BST North

In our fast-paced world of manufacturing, where precision and efficiency are paramount, the role of web guiding cannot be overstated. As we navigate through an analog landscape fraught with chaos and imperfections, web guides serve as indispensable tools, allowing us to cut through the uncertainties and produce high-quality products consistently. By simply correcting web misalignments to improve roll-to-roll processes, web guides play a pivotal role in optimizing manufacturing, reducing waste and ultimately enhancing profit margins by conserving materials — a truly "green" aspect of the converting industry.

We can all agree and acknowledge that there are no perfect webs or machines; web guides serve as the key components in any converting machine. They ensure that each step of the converting process is executed with precision and accuracy. Depending on how your machine is de pending on how your machine is designed, you can elect to use an "edge" guide by employing one sensor or a "centerline" guide by utilizing two sensors, one on each side of your web. Another common application is guiding a printed line or image with a camera or contrast sensor. To address all sections of a roll-to-roll process, there are four main types of web guide applications.

The Four Major Types of Web Guides

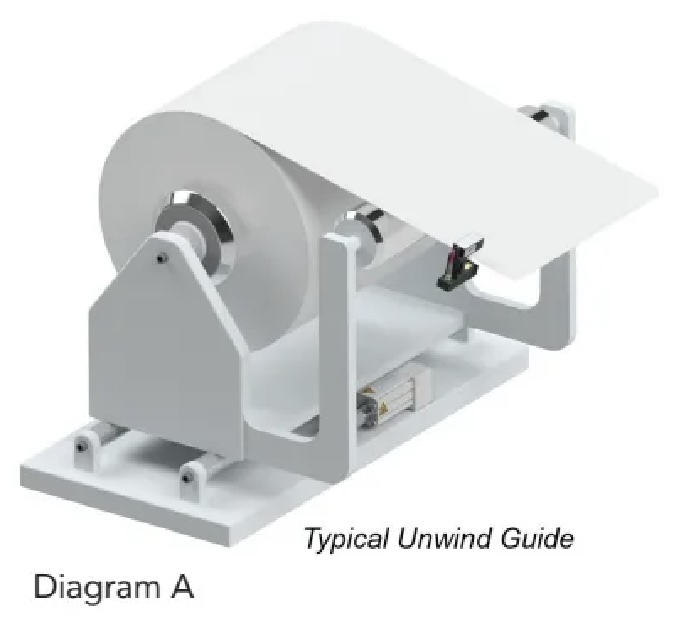

- Unwind Guides: These guides set the stage for the converting process by addressing issues such as edge variations on parent rolls, poorly wound rolls, splices in roll materials, and telescoped or randomized rolls of web material. Unwinds are lateral shifting applications where the roll is moved with respect to sensors) that are fixed to the machine or floor — think of these as guiding to a fixed point in space. Proper web geometry is critical for these to work properly (see Diagram A), and they always include a shifting exiting idler roller to maintain the web path through your sensors. By eliminating these initial sources of error, unwind guides ensure a smooth start to the converting process.

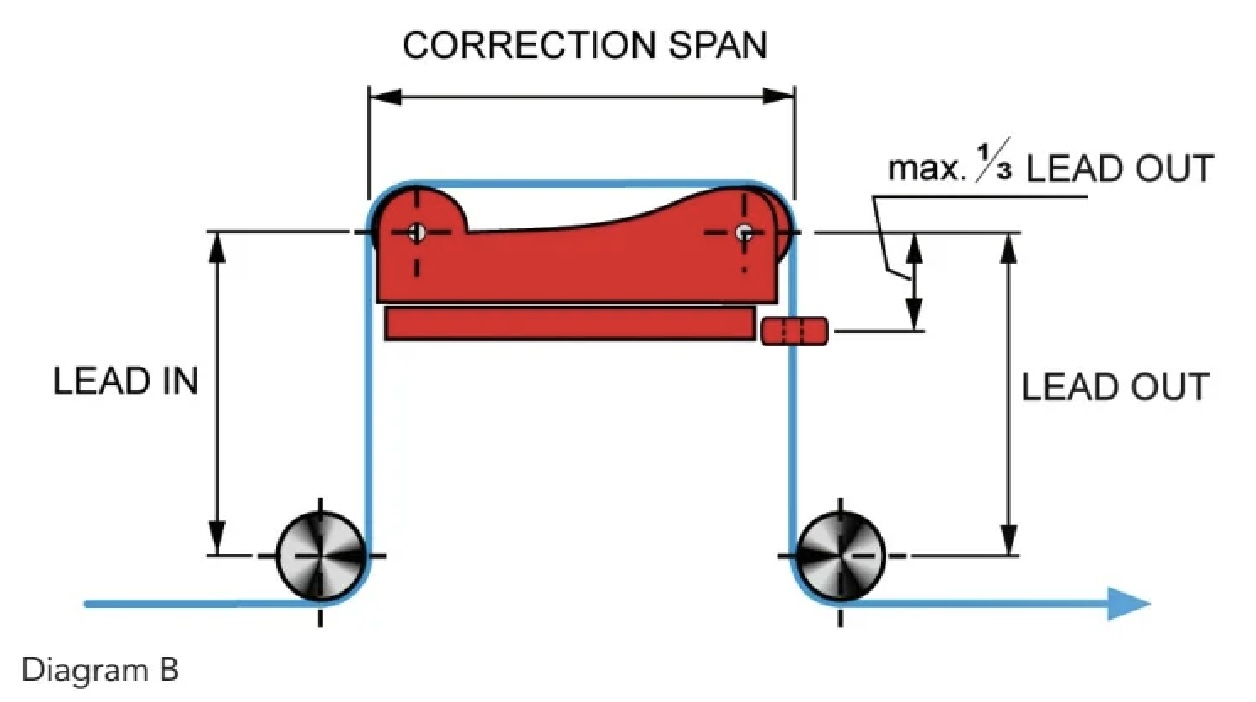

- Positive Displacement Guides: Ideal for aligning webs before intermediate processes such as coating applications, positive displacement guides offer precise alignment and instant make-ready capabilities. They are also particularly crucial before printing, slitting or die-cutting applications, helping to maintain smooth and efficient process while minimizing scrap material. Again, proper web geometry is required to ensure good guiding results and a good rule of thumb is a full to a half a web width for lead-in and lead-out spans, (see Diagram B). It is also good practice to place sensors in the first 1/3 of the lead out span. This type of guide has the widest flexibility since you can use it with various web paths like an S-wrap or Z-wrap, along with the standard overwrap web path.

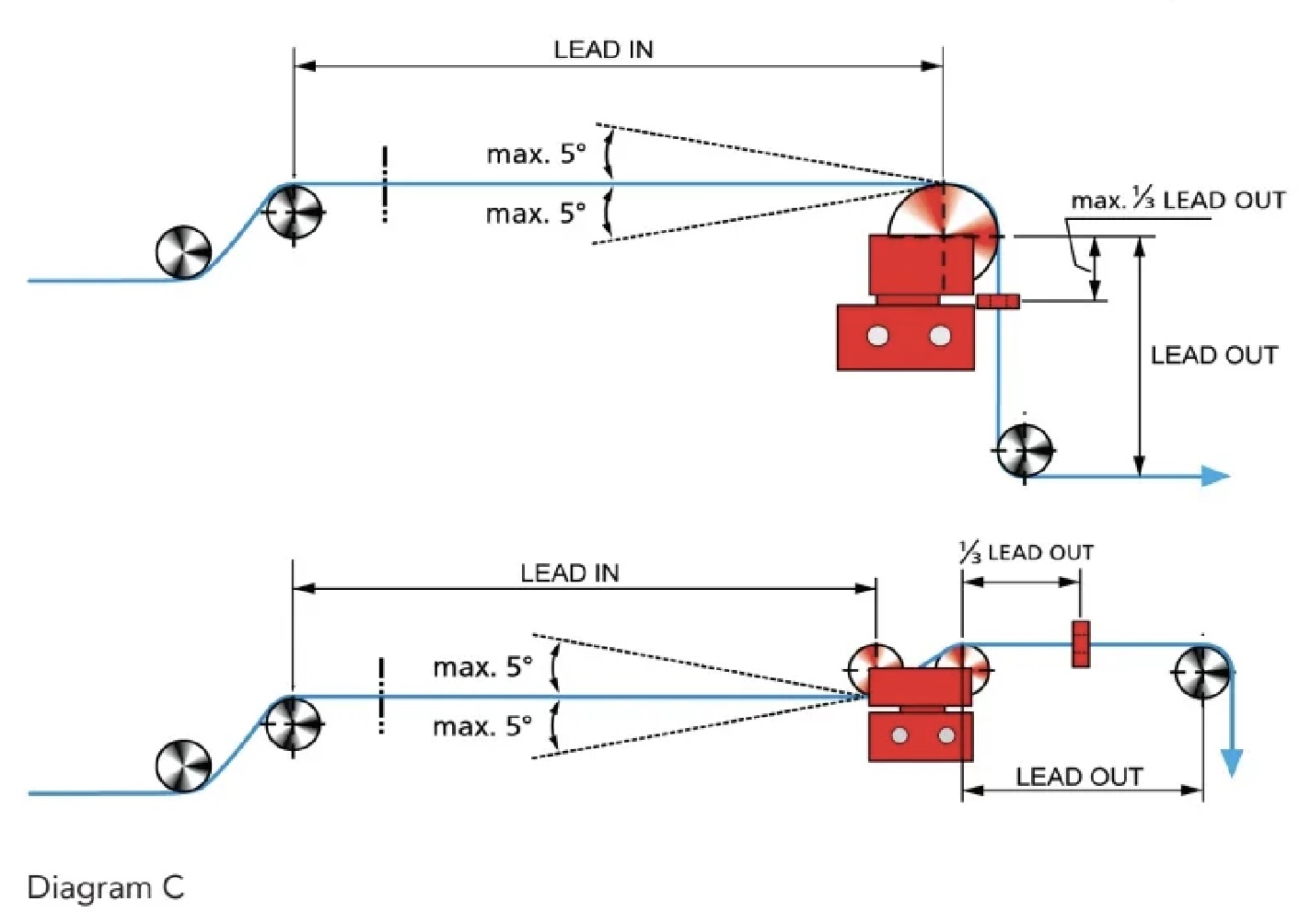

- Steering Rolls: Whether single or double, steering rolls act as web benders. They are best utilized with a long lead-in span, such as the exit of an oven or dryer, to prevent wrinkling or deformation of the material. For lighter gauge films, foils and non-wovens, estimate 1.5 - 3 web widths for lead-in with a half- to a full-web width for lead-out distance, (see Diagram C). For heavier gauge films and foils, rigid materials, increase the lead-in to 5-10 web widths. The longer the better is best for any steering roll application. Proper utilization of steering rolls is essential to avoid defects and maintain product quality.

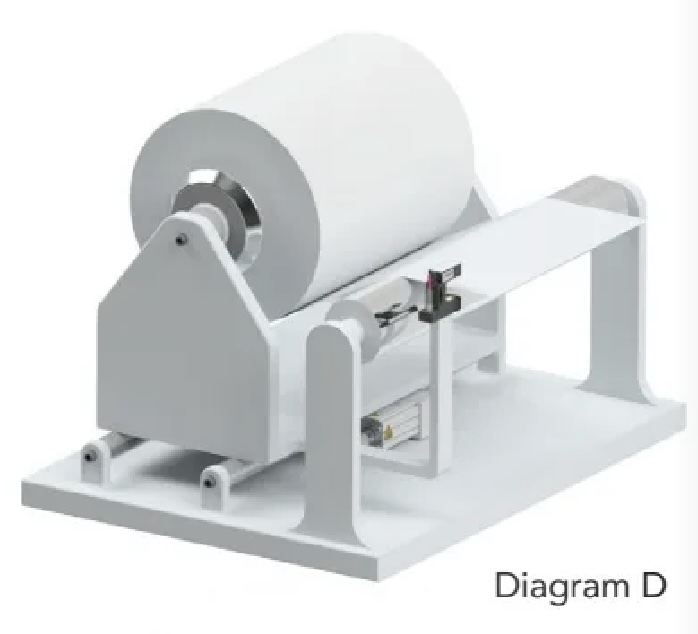

- Winders (Rewinders): As the last step of a roll-to-roll process, winders play a critical role in producing final product rolls. Winder guides actively chase the web, ensuring precise winding and produce neatly wound rolls with straight, box-edge results. Winders are the opposite of unwinds where the sensor moves with the roll on the lateral side shifting device (see Diagram D). Additionally, winders can be used to randomize or oscillate the winding pattern, preventing issues such as bowed or saddle rolls by breaking up any gauge bands in your web. In these cases, you either oscillate the guide point of the sensor electronically or motorize the sensor in a sinu-soidal or saw tooth wave form.

The Importance of Web Tension

While web guides are indispensable for maintaining alignment and ensuring smooth processes, their effectiveness hinges on proper web tension. Without adequate tension, even the most sophisticated web guides will fail to deliver the desired results. Integrating a robust load cell or tension roller alongside a controller and brake or drive mechanism establishes a closed-loop system to ensure consistent web traction on the machine’s idlers. This is a must and any attempts to guide an untensioned web is akin to guiding a limp noodle — it’s an exercise in futility.

Conclusion

In conclusion, the significance of web guiding in the converting industry cannot be denied. Web guides stand as indispensable tools, allowing us to "guide" through the complexities of any roll-to-roll converting process with ease. From addressing initial errors during unwinding, to ensuring precise alignment before critical intermediate processes like printing or coating, and finally, producing smooth, book-edge rolls in the winding/rewinder process, the four major types of web guides play crucial roles at every step. By improving alignment and minimizing waste, web guides pave the way for increased profitability and reducing your carbon footprint. Two important goals for any manufacturer in our world today.

About the Author

Jason Vanderpoel has more than 25 years of experience in the converting/automation industry and is a proud University of Wisconsin-Madison graduate with a BS in Mechanical Engineering. He presently holds the position of Web Guide Sales Manager at BST North America, a global provider of AccuWeb and BST web guides. He can be contacted at This email address is being protected from spambots. You need JavaScript enabled to view it. or linkedin.com/in/jason-van-derpoel-2423272/