Web Handling | To Break or Not To Break--What is the Tension?

- Published: December 03, 2012, By Timothy J. Walker

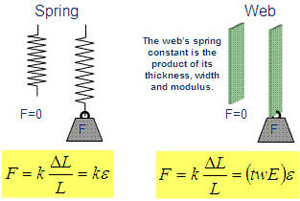

Actually, the question is: What tension will cause a web to break or deform? It all comes down to a material’s property. In all materials, breaking and deforming will occur in response to not just force, but force exerted over a given cross-sectional area. In tensioning a web, the cross-sectional area is the width times the thickness.

A web is like a beam. In comparing wood boards, a 2 x 4 will have more strength than a 1 x 2 and less strength than a 4 x 4 or 2 x 8. Also, a pine board 2 x 4 will be stronger than a 2 x 4 of balsa wood, but weaker than a 2 x 4 made of oak or maple. It all comes back to a material’s property.

A web is like a beam. In comparing wood boards, a 2 x 4 will have more strength than a 1 x 2 and less strength than a 4 x 4 or 2 x 8. Also, a pine board 2 x 4 will be stronger than a 2 x 4 of balsa wood, but weaker than a 2 x 4 made of oak or maple. It all comes back to a material’s property.

The same is true with webs. Material, thickness, and width will all contribute to a web's strength and resistance to breaking or deforming (a.k.a. yielding). A 1-in. wide web will break easier than a 10-inch wide web. A 2-mil thick web will be harder to break or yield than a 0.5-mil thick web. A steel web will be harder to break than a polyethylene web. (Harder to break = higher critical tensile break stress.)

The best way to find your web’s break or yield point is to perform a tensile-elongation test. Elongation distance and force is measured by using a tensile-elongation tester that pulls on a strip of web in a very precise manner. Converting the load vs. length change data to find the initial slope of stress and strain plot defines the web's Young's modulus.

If all this is true, you say, why can aluminum foil easily break but a box of cling wrap entails a wrestling match to tear it? The difference is in the ability to concentrate an applied force over a small area.

With aluminum foil, you can easily skew the sheet, load everything on an edge and initiate a tear. With cling wrap, as you skew the sheet, the heavily loaded side will elongate, taking a high portion of the load you have exerted, but the stresses will still be distributed across a large area, not just the cling wrap's edge. To tear the cling wrap, you need help with concentrating the stress, so the cling wrap box includes a serrated blade to focus your load over the small blade tips or a slide cutter that initiates a tear, creating the critical tear stress required.