A New Era in Sustainable Packaging

- Published: March 27, 2024

Development of Compostable Shrink Film Technology

By Ana Juraga Oluic and Julie Holmquist, Communications Division, Cortec® Advanced Films

Shrink wrap packaging material is usually made from polymer plastic film. When heated, it shrinks tightly over the item it is covering. Shrink wrap and shrink film are very versatile materials and can be used in a large variety of packaging applications like wrapping food, gift baskets, boxes, etc. It keeps products safe from outside elements, increases shelf life and provides tamper-proofing.

Shrink wrap packaging material is usually made from polymer plastic film. When heated, it shrinks tightly over the item it is covering. Shrink wrap and shrink film are very versatile materials and can be used in a large variety of packaging applications like wrapping food, gift baskets, boxes, etc. It keeps products safe from outside elements, increases shelf life and provides tamper-proofing.

Shrink wraps are manufactured to bind product components to prevent spillage and ensure proper storage, especially during shipping. They usually consist of a polymer plastic wrap which poses sustainability disadvantages. Dangers of plastic have become widely known. Conventional plastics cannot compost or biodegrade. This enables plastic features such as stretchability and strength, but it also makes it impossible to naturally degrade in the environment. Compostable plastics provide an earth-friendly option with little change in how they are used.

Compostable shrink wrapping film is designed to fit the circular economy concept while meeting common packaging needs. It is made with certified commercially compostable resins and designed for use in standard heat-shrinking applications. Users can shrink wrap small or large components as normal for a streamlined fit conforming to the shape of the object. After use it can be disposed of in a commercial composting environment to reduce the amount of plastic packaging that normally ends up in a landfill. The film is shelf and curb stable and will retain its integrity until disposed of properly.

Today, films with a “green” aspect — whether with an eye to more environmentally responsible end-of-life disposal options (e.g., commercial composting instead of the landfill) or the use of renewable raw materials (i.e., biobased resin) have been developed. In 2021, evidencing continued commitment to greener packaging solutions, new or updated films were designed for disposal in a commercial composting environment. The following represent the wide variety of formulations based on commercially compostable resins.

Commercially Compostable Stretch Film is for use on automated stretch wrapping equipment. This film is made with certified compostable resin and a tackifier additive. It is extremely elastic and can be used to replace standard stretch wrap film used in many different applications: Palletizing of goods for warehousing or shipment, wrapping hay bales, bundling luggage, moving furniture, packaging construction material, and corralling appliances and other items.

Given its vast potential application in a market that already uses millions of kilograms of stretch film annually, this technology invites industries to replace a common plastic wrapping material with a film that can eventually be turned into soil amendment at a commercial composting facility after use.*

Commercially Compostable Corrosion Inhibiting Stretch Film has the added feature of corrosion protection. This commercially compostable film is perfect for stretch-wrapping applications that involve metal equipment or components. It can be used for corrosion protection when wrapping appliances, brake rotors, heat exchangers, steel coils, and countless other metal raw materials or manufactured goods for domestic shipment or international export.

During transport, or even storage, goods may pass through fluctuating climates, temperatures and humidity levels that could lead to condensation and corrosion on new metal surfaces. When this occurs, the corrosion inhibitors compounded into film wrap provide protection by forming a molecular corrosion inhibiting layer on the surfaces of the metals wrapped inside.

When the packaging is removed, the corrosion inhibitors do not require special cleaning because they simply float away through natural vapor diffusion. In this way, the film powered by Nano VpCI streamlines corrosion protection as part of the normal stretch wrapping process while simultaneously opening up a new disposal option for the eco-conscious customer.

Commercially Compostable Shrink Film

Balancing shrink wrapping with biopolymers and compostability is challenging but scientists have found the right formulation.The film is 45 percent biopolymer with a completely different texture than stretch film because it has a different purpose: heat-shrinking to seal and conform the film to the shape of the object wrapped inside. It is thick and slippery to handle but extremely amenable to the use of a compostable resin containing 45 percent biopolymer, or plant-based resin.

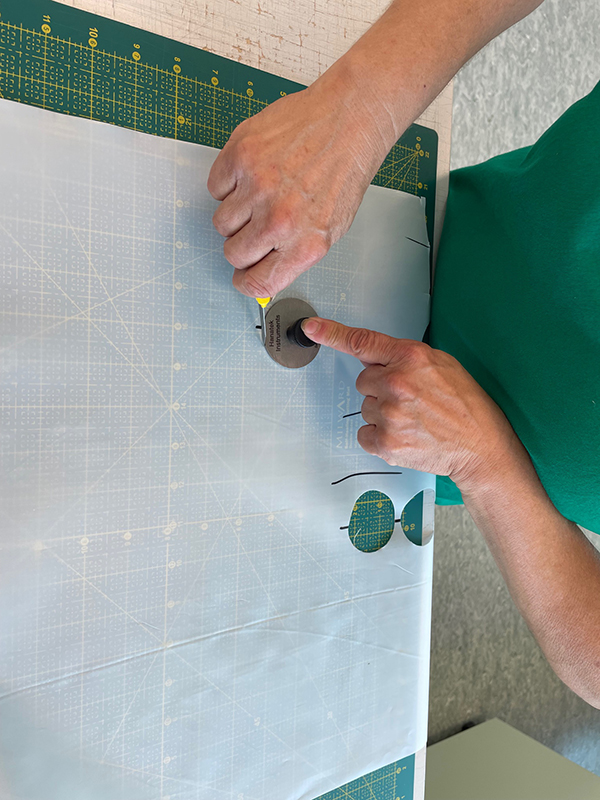

While it is made from different materials than normal shrink wrap, the film can be used in basically the same manner. The unit being wrapped should be measured to calculate the amount of film needed, allowing for overlap at seams. Sharp edges and corners should be padded off. Then the item can be wrapped in the film using standard heat shrink tools to first seal the edges and finally shrink the film to an object’s shape. This commercially compostable shrink film is designed to be shelf and curb stable and can be used to keep dust and moisture off warehouse stock until the film is no longer needed and can be disposed in a commercial composting environment.

Overcoming Challenges

As for almost any accomplishment, the development of commercially compostable films is not without extensive time and effort. A company’s team works closely with its resin suppliers to find the best raw materials for the job. Once the specific configurations and resins have been selected, much of the action shifts to the production floor for trial.

The team typically starts by running experimental batches on one of the smallest extrusion lines. Formulations that pass the first round and seem promising go on for further trials on larger extrusion lines. As the team tests different formulations, they compare the results to what the customers need and select the best all-around formula.

When it comes to achieving compostability, it is important to look at ASTM D6400 guidelines for commercially compostable film. One requirement they must meet is to keep non-biodegradable material below a certain threshold, equivalent to only a trace amount in the entire film. The film also undergoes testing in an in-house laboratory and its composting chamber to see if the film will break down within the ASTM specified timeframe.[1]

Successful compostable films formulation and production require manufacturers with the resolve and stamina to tackle and overcome special challenges that accompany the use of atypical plastic resins. Probably the biggest challenge is that these plastics tend to behave drastically different than normal materials and learning how to work with each one and make a successful product can be tricky. They don’t mix well together and everything must be cleaned out of the extruder. Every little thing from temperatures that must be set to the speed of the material flowing through the machine needs to be adjusted to maintain peak efficiency while still running a high quality product.

Through research and development, a company can do this with multiple commercially compostable films, giving customers a wide range of options to choose from in their plastics packaging — from organic waste collection bags to commercially compostable shrink film and corrosion inhibiting stretch film. The R&D vision never stops, so it is highly likely that new varieties of compostable films will continue rolling off the extrusion lines in the coming years.

*In reference to a commercial composting facility operated in accordance with best management practices. Check locally to see if such a facility exists in your community and if they will accept these products. Not suitable for backyard composting.

ABOUT THE AUTHORS

Ana Juraga Oluic is corporate communications manager at Cortec Corporation. She has been a content writer at Cortec for 13 years. Besides handling media relations, she collaborates with Cortec’s engineers and chemists in creating informative technical content. Julie Holmquist has been a content writer at Cortec Corporation for more than eight years. She specializes in writing about corrosion-inhibiting technology for concrete, electronics, manufacturing, oil-and-gas and many other industries. They can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it. or This email address is being protected from spambots. You need JavaScript enabled to view it.