The Power of One

- Published: January 31, 2006, By Edited by Nsenga Byrd Thompson, Associate Editor

Web Exclusive

In order to increase efficiencies and improve quality, Columbus Container Inc. (CCI), a mid-size corrugated container supplier, needed to streamline its computing systems and integrate its workflow process across six plants.

CCI had used many disparate systems to perform estimating, quotation, scheduling, warehousing, and shipping to gain productivity and efficiency benefits, but these systems did not work with one another. Nor did all plants run the same system, causing further isolation and increased redundancy across the entire organization. CCI management knew it had to improve cross-plant efficiencies to compete.

The Columbus team began considering an upgrade to create one system that would help resolve many of these issues. CCI’s director of information services, Bob Combs, led the transition, turning to VantagePoint to manage the challenging process of selecting, implementing, and customizing a solution, while recognizing that CCI would need support during and after the migration, including training, customization, installation, and support services.

“VantagePoint was the logical choice for us given their exclusive focus on packaging manufacturers, their support capabilities, and their commitment to managing the entire transition process including custom training,” says Combs. “VantagePoint offered products and services we simply could not obtain from other vendors.”

Engineering a Solution

VantagePoint application engineers spent several weeks interviewing CCI’s plant, warehouse, operations, and information technology personnel to understand exactly how they wanted the new software to work.

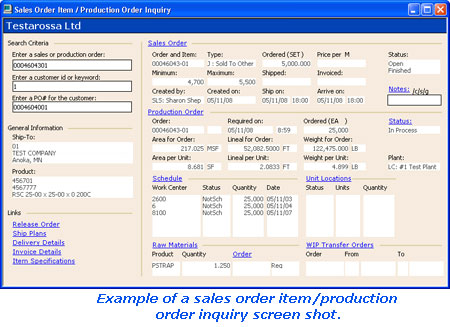

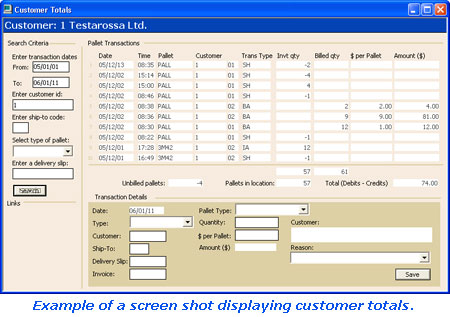

The solution VantagePoint created utilizes Business VantagePoint’s costing, estimating, quotations, order processing, warehousing, shipping, procurement, invoicing, and sales forecasting. In addition, the system works across multiple plants and is customized to reflect CCI’s unique workflow processes.

“The entire implementation process took just three months including training,” recalls Combs. “As director of information systems, I was sure that my phone would be ringing off the hook once we went live. But I received only a few e-mails and calls on the first day. Thanks to VantagePoint, nearly everyone was working productively from the beginning and none of our project timelines slipped during the transition.”

CCI reports it has experienced substantial productivity gains. “Business VantagePoint automates many time-consuming clerical tasks,” Combs says. “Not only that, but it encourages costing and estimating exploration and client collaboration. We were always reluctant to change design elements because of the subsequent need to rework all the details. With the new system, changes are automatically communicated down to the plant floor and our team can concentrate on creating customer-focused packaging solutions, which is after all, why clients come to us in the first place.”

Reports Combs, “We knew we could seriously increase efficiencies if we streamlined business systems and enabled our six plants to work together. VantagePoint made our transition painless, and the system enables us to meet customer needs while at the same time increasing productivity. If we had to do it all over again, we would definitely work with VantagePoint,”

CONVERTER INFO:

Columbus Container Inc.

3460 Commerce Dr.

Columbus, IN 47201

812/376-9301

SUPPLIER INFO:

VantagePoint—vpgroup.com