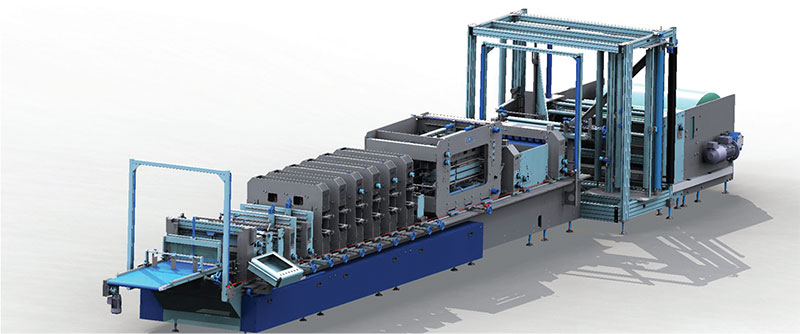

ELBA S.p.A. manufactures the most customizable bag and pouch making machines

- Published: February 07, 2024

ELBA has been designing and manufacturing automatic high-speed bag and pouch making machines since 1956.

More than 2.500 active installations worldwide serve different markets (food, pet food, groceries, dairy, chemical, diapers, agricultural, courier and much more), including medical and pharmaceutical ones.

ELBA offers tailor-made solutions and provides commissioning, training and after-sales support. The modular design allows the machines to be customized and their configuration can be upgraded at any time, to face new unpredictable market demands.

The ELBA machines can produce different kinds of bags and pouches:

- the SA-V machine can manufacture stand-up/Doypack, side gusset, center seal and 2/3 side seal pouches;

- the SA-U machine can produce simple bottom/side sealed bags, gusseted bags, boutique bags, STEB, courier bags, heavy-duty bags and much more;

- the SA-M machines can manufacture high-quality pouches, header bags and flat and gusseted reels for the medical and pharmaceutical markets;

- the SA-W machine can produce a wide range of wicket bags like bottom gusset bags, bread bags, poultry shrink bags, hygiene bags and diaper bags;

- the SA-V/TVB can manufacture high-barrier shrink bags with straight/curved bottom seals and side seals.

All the machines can run with recyclable films, as proof of the ELBA commitment to the environment and attention to the customers’ needs. Furthermore, they are equipped with a kinetic energy recovery device which ensures savings of up to 20% on total energy consumption.

Thanks to the mechanical processing department and the sister company FAE, 80% of the machine parts are produced in the ELBA facilities, ensuring high-quality controls during the whole process and the utmost attention to the smallest details.

The machines are fully equipped with Siemens components and are entirely controlled by a state-of-the-art HMI based on Profinet®, one of the most advanced communication protocols that controls each of the installed stations/tools independently and in real-time and, consequently, the whole production process. Each station is independent, servo-driven and plug & play.

The Siemens connection system, installed on all the machines, enables the service department to offer real-time and on-site technical support within 24 working hours.

Thanks to manufacturing and technological capacities and as a result of constant investments in R&D, ELBA develops advanced and patented solutions, serving the market innovatively and efficiently.

Attention, high accuracy and the perfect combination of technological and manufacturing capacities are the keystones of the ELBA strategy.

For more information, contact us at sales@elba-spa.it and visit our website at www.elba-spa.it