Coating Matters | The Wizard Behind the Curtain

- Published: September 16, 2013, By Claudia Hine

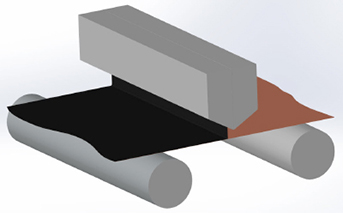

Do you sometimes feel like you are free falling through the coating world? A free fall can be a good thing if you are not spinning out of control, but the distance is just right and the free fall is intentional. A good example is the use of a slot die to coat fluid with the process technique of curtain coating (see Figure 1).

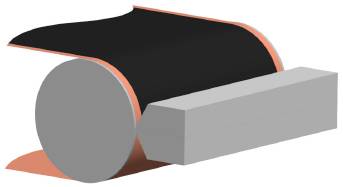

It’s not magic that makes curtain coating work, but physics and fluid dynamics. Just like in proximity coating (see Figure 2), the key to curtain coating is to displace the air near a substrate with a fluid. The major difference is that you are in the range of 10 cm away from the substrate instead of 10 microns.

So how can this process provide the same response? It doesn’t. Well, not exactly. Curtain coating has the added concern of what happens to the fluid sheet as it drops from the slot die lip opening. With a long distance to drop, it is important that the edges of the fluid are guided to meet the substrate. Edge guides are added to the slot die to allow for the liquid to adhere to a physical constraint overcoming the edge effects of the gravitational flow through disrupting the natural surface tension of the fluid. If the edge guides were not available for the fluid to adhere to, the fluid would bead in on itself, making a narrow curtain with thick edges. In essence, the curtain closes.

With the fluid sheet edges controlled and the large gap, curtain coating is an ideal arrangement for coating substrates that are irregular or discrete parts. Of course with discrete parts, the flow of fluid will cover more than the part passing by. Those familiar with photographic film coating will be very familiar with curtain coating. Since photographic film has been largely displaced by digital photography, what other applications see a benefit with this process?

Any application that can benefit from the extended distance from the slot die (think large substrate variations) or high production speeds (think “thin—fast—and in one pass” products). The fluid obtains an increased velocity as it impinges the substrate and displaces air more rapidly.

So, if curtain coating is so great, why isn’t everyone doing it? While curtain coating does have advantages, there are issues also including vibrations and flow rate precision control. Small disturbances in the web control can cause noticeable effects in coating caliper and consistency. Also, while a consistent flow rate is always important in slot die coating, utilizing a flow meter is especially important in curtain coating.

So whether you choose to operate a slot die in close proximity or from a distance measurable with the human eye, coating follows the same laws of physics. The question is whether the fluid dynamics are on the micro or macro scale. The increased gap and speed of the curtain coating technique probably has started turning some wheels in your head, but ultimately it is your choice to coat with or without a curtain. Happy coating!

Mark D. Miller, author of PFFC's Coating Matters column, is a fluid coating expert with experience and knowledge in the converting industry accumulated since 1996. Mark holds a Bachelor's degree in Chemical Engineering from the Univ. of Wisconsin-Madison and a Master's degree in Polymer Science & Engineering from Lehigh Univ. and a Juris Doctor from Hamline Univ. Mark is a technical consultant and CEO of Coating Tech Service LLC. He has worked in web coating technologies and chemical manufacturing operations and is a certified Six Sigma Black Belt trained in both DMAIC and DFSS disciplines. Coating Tech Service provides process troubleshooting and project management for precision coated products. Mark has extensive process knowledge in high precision coating applications including thin film photo voltaic, Li-Ion battery, and optical systems technology. Mark has been integral to new developments and technology that minimize product waste and improve process scalability.

Mark D. Miller, author of PFFC's Coating Matters column, is a fluid coating expert with experience and knowledge in the converting industry accumulated since 1996. Mark holds a Bachelor's degree in Chemical Engineering from the Univ. of Wisconsin-Madison and a Master's degree in Polymer Science & Engineering from Lehigh Univ. and a Juris Doctor from Hamline Univ. Mark is a technical consultant and CEO of Coating Tech Service LLC. He has worked in web coating technologies and chemical manufacturing operations and is a certified Six Sigma Black Belt trained in both DMAIC and DFSS disciplines. Coating Tech Service provides process troubleshooting and project management for precision coated products. Mark has extensive process knowledge in high precision coating applications including thin film photo voltaic, Li-Ion battery, and optical systems technology. Mark has been integral to new developments and technology that minimize product waste and improve process scalability.