Coating Matters | Steam Remoisturizing Technology for Paper-Based Labels, Pt. 2

- Published: August 20, 2014, By Mark Miller and Joseph E. Martin

In Part 2 of this two-part series, the authors provide the criteria for choosing a remoisturizer solution.

TECHNIQUES FOR STEAM REMOISTURIZING

There are different techniques for applying steam to the cross direction of a moving paper web. The simplest and least expensive means of applying steam is through the use of passive steam showers. These essentially employ a tube the length of the web’s cross direction that is equipped with drilled holes that allow steam to escape. The tube is mounted over the web downstream of the ovens and is connected to a steam source supplying continuous saturated steam at a nominal pressure (see Figure 3).

This technique, although relatively inexpensive, has several disadvantages. One, there is no way to control the moisture profile across the web (a key variable process engineers want in SPC for label manufacturing) since all the holes in the tube are drilled to the same diameter and, if not plugged, will produce the same amount of steam.

This technique, although relatively inexpensive, has several disadvantages. One, there is no way to control the moisture profile across the web (a key variable process engineers want in SPC for label manufacturing) since all the holes in the tube are drilled to the same diameter and, if not plugged, will produce the same amount of steam.

Two, controlling where the steam condenses is impossible since it is open to the atmosphere. Condensate may form on the tube’s exterior or on adjacent web handling equipment and eventually drip onto the coated web causing product quality problems.

And finally, the effectiveness of imparting the desired moisture is less than other closed system methods since the steam showers are susceptible to air currents and the penetration of the steam into the fibers of the paper is minimal.

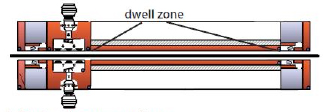

Another technique for applying steam is through the use of a closed system applicator (see Figure 4). Such applicators enclose the web long enough for multiple steam sprays from either or both sides to impart the required amount of moisture to the paper. The steam is applied at near saturation temperature across the web from individual steam valves spaced at intervals down to 6 in. apart. The amount of moisture absorbed by the paper is determined by the temperature of the web entering the enclosure, the density of steam touching the web, and the dwell time or time that the steam is in contact with the web.

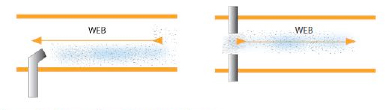

There are basically two types of enclosed steam applicators: lazy steam or streaming steam applicators (see Figure 4a) and impingement applicators (see Figure 4b). Streaming steam applicators spray steam parallel to the web and rely on the Coanda effect to absorb the steam onto the web.

The Coanda effect states that a fluid or gas stream will hug a convex contour when directed at a tangent to that surface. However, since the web is moving, it creates a counter phenomenon called “ground effect,” which causes a cushion of air to exist between the web and the steam until they make contact. Hence, the dwell zone must be longer or the speed of the web slower to achieve the optimum dwell time to maximize moisture absorption.

Impingement applicators use high velocity or pressure sprays to inject saturated steam directly into the fibers of the web, thus enabling the addition of up to 3% additional moisture. These sprays contain minimal entrained air so the density of steam is maximized. The steam contacts the web immediately when it enters the enclosure, and the steam continues to contact the web until it leaves the enclosure. Hence, for a given web speed, the dwell zone can be shorter to produce the same web/steam exposure time (dwell time). Or, if the dwell zone is longer, the web can absorb the same amount of moisture at a higher machine speed.

CRITERIA FOR CHOOSING A REMOISTURIZER SOLUTION

Before selecting a remoisturizer solution, several process criteria should be considered.

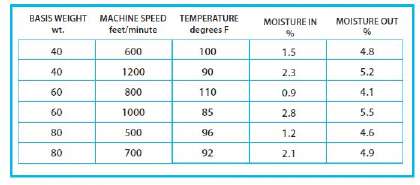

It is a good idea to request production application data from suppliers that shows that their units can provide the required amount of moisture for the machine speeds, coating application, and basis weight of the paper that will be running. Or, if possible, visit an existing installation or speak with the process engineer or plant manager.

Table 2 is an example showing the percent moisture before and after remoisturizing for a silicone-coated release liner using different paper stocks.

Temperature measurements of the web should be taken at the location where the remoisturizer will be installed. The ideal temperature for the web entering a closed system steam applicator is between ambient and 125 deg F. This will ensure that maximum condensation occurs on the web. If the web temperature is above the ideal range, it may be necessary to install chill rolls in front of the remoisturizer to bring the temperature to within the ideal range.

The unit should be totally sealed to prevent fugitive steam from escaping and condensing on web handling equipment. Also, the outer surface of the applicator should be heated during start-up so no condensation occurs but not hot enough to cause safety issues if touched by plant personnel. Any condensation that forms on the exterior of the applicator or other web handling equipment can drip on the web and cause product quality problems.

Materials and welds used to manufacture the steam applicator should be of the highest quality alloys to minimize maintenance and downtime over the life of the unit. Stainless steel and titanium are proven to enable welds to accommodate thermal expansion. A 12-ft-long steam applicator can expand up to ½ in. when heated, so it is important that welds won’t crack in order to minimize leaks. The valves also should be robust enough to withstand years of cycling without replacement.

Controlling moisture to a target percent is possible to achieve with automatic controls. One automatic control strategy for minimizing curl is to ensure the moisture content in the finished product is approximately the same as the moisture content of the paper used at the unwinder or before the curing oven. This can be accomplished by using two IR moisture sensors with two PID control loops. The first IR sensor cascades the set point for the control loop receiving the signal from the second IR sensor, which sends an output signal to the steam valves to adjust flow accordingly.

Since most steam applicators provide multiple valves for controlling moisture in the cross direction, the IR sensors can be mounted on a scanner or can be moved manually if mounted on a sliding mechanism to check for consistency across the web. A PLC can provide the necessary digital interlocks for start-up, shut-down, and rethreading. Color displays representing key process variables also make it easier for operating personnel to respond to alarms and make adjustments.

Finally, it is more cost effective if the steam applicator can be fabricated to fit an existing process line vs. forcing plant personnel to accommodate a standard size applicator. This flexibility saves downtime for installation and costly modifications to web handling equipment. Hence, the total cost of ownership is minimized.

CONCLUSION AND ECONOMIC JUSTIFICATION

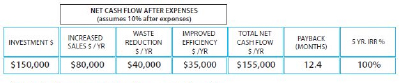

Steam remoisturizing label stock is an effective method of reducing curl and producing “lay flat” product. The typical economic payback for steam remoisturizing systems is between 12 and 18 months. The IRR, which can be achieved, will vary according to the parameters for each unique application. However, the parameters that will contribute most to IRR include incremental sales from the availability of “lay flat” product; reduced material scrap; and improved production efficiencies.

Table 3 illustrates the results a label manufacturer with annual revenues between $40 milltion and $50 million could expect to achieve with a single remoisturizer control system on the adhesive coating line.

For Part 1 of this article, click here.

Mark D. Miller, author of PFFC's Coating Matters column, is a fluid coating expert with experience and knowledge in the converting industry accumulated since 1996. Mark holds a Bachelor's degree in Chemical Engineering from the Univ. of Wisconsin-Madison and a Master's degree in Polymer Science & Engineering from Lehigh Univ. and a Juris Doctor from Hamline Univ. Mark is a technical consultant and CEO of Coating Tech Service LLC. He has worked in web coating technologies and chemical manufacturing operations and is a certified Six Sigma Black Belt trained in both DMAIC and DFSS disciplines. Coating Tech Service provides process troubleshooting and project management for precision coated products. Mark has extensive process knowledge in high precision coating applications including thin film photo voltaic, Li-Ion battery, and optical systems technology. Mark has been integral to new developments and technology that minimize product waste and improve process scalability.

Mark D. Miller, author of PFFC's Coating Matters column, is a fluid coating expert with experience and knowledge in the converting industry accumulated since 1996. Mark holds a Bachelor's degree in Chemical Engineering from the Univ. of Wisconsin-Madison and a Master's degree in Polymer Science & Engineering from Lehigh Univ. and a Juris Doctor from Hamline Univ. Mark is a technical consultant and CEO of Coating Tech Service LLC. He has worked in web coating technologies and chemical manufacturing operations and is a certified Six Sigma Black Belt trained in both DMAIC and DFSS disciplines. Coating Tech Service provides process troubleshooting and project management for precision coated products. Mark has extensive process knowledge in high precision coating applications including thin film photo voltaic, Li-Ion battery, and optical systems technology. Mark has been integral to new developments and technology that minimize product waste and improve process scalability.

Joseph E. Martin has more than 30 years of experience as an executive bringing new automation and productivity solutions to market within Fortune 500 and start-up technology companies. He has held management positions with Fisher Controls Intl., Measurex Corp., Compuware, and a number of smaller software and systems companies, including his own start-up. Current he represents Qualitek-VIB Systems, Tucker, GA, a company providing automation solutions to the corrugating and paper converting industries. Joseph holds a BS in Petroleum Engineering and an MS in Engineering Management from the Missouri University of Science and Technology.