Coating Matters | Pressure-Sensitive Adhesive Coating

- Published: April 22, 2015, By Mark Miller

If you'd like to hear from Mark Miller's own lips rather than read his column, titled "Coating Matters | Pressure-Sensitive Adhesive Coating," click on his podcast below:

{mp3}ps-adhctg-voice{/mp3}

When looking for process, product, and profit improvements for your PSA tapes and labels, consider going back to the drawing board.

Pressure-sensitive adhesive (PSA) coating is common for tapes and labels and useful for many market applications. This is a broad area that has many caveats, with the range of coating chemically spanning low solids content within a solvent to 100% solids hot melt adhesive coating. With these changing chemistries comes many decisions, from pump type to substrate interaction energy to coating head system.

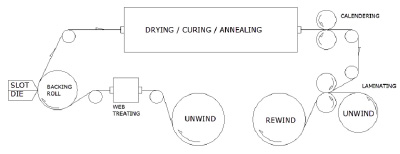

![]() When deciding on coating methods for PSA chemistry, there are various options, but one consideration is connected with the adhesive formulation. To reduce the use of curing energy and to speed up the process, reducing solvent content can provide advantages.

When deciding on coating methods for PSA chemistry, there are various options, but one consideration is connected with the adhesive formulation. To reduce the use of curing energy and to speed up the process, reducing solvent content can provide advantages.

The curing step in coating is typically the bottleneck. Whether it is oven curing or drying, UV curing or eBeam, the curing technology takes some time based off the interaction with the chemistry. Understanding whether solvents are simply being dried off, or if the adhesive is reacting to form a complex molecule, will dictate the limits of the curing process and subsequently the line speeds.

So how do you develop an understanding of the chemistry and the subsequent connection to curing? The analytical techniques and chemistry knowledge for specific adhesives can be determined through discussions with adhesive suppliers or through analytical equipment and testing sources. After discussions with the adhesive supplier are complete, analytical testing, including rheology and molecular level studies of the adhesive in fluid form, can provide an understanding of the makeup of the liquid prior to coating. This also provides the basis for understanding the fluid flow phenomenon and how it will interact with the coating technique.

While many coating techniques require a specific viscosity range in order to coat successfully, there are coating technologies that can successfully coat viscosities from 1–100,000 cP or more. These coating systems allow for maximum flexibility in formulation development and the possibility of reduced energy use and maximum line speed. In a return on investment calculation for coating system technology, this should be a consideration. While there will be time associated with re-formulation by chemists and product development engineers, the savings may be more than covered in the increased line speeds of the production process.

As an example, imagine that the PSA formulation is 20% solids and can be run at 50 fpm. Oven drying is responsible for the final product morphology and product quality results. To run 100 fpm, the PSA would need to be reformulated to 40% solids. This reformulation may take a chemist two months, but the money spent in this product change can be recovered in a short time of increased production; typically days or weeks instead of months waiting for an equipment change.

Sometimes the best next step is to find your way back to the beginning! When looking for process, product, and profit improvements for your PSA tapes and labels, consider going back to the drawing board and establishing a strong understanding of the chemistries and molecular development before moving forward.

Mark D. Miller, author of PFFC's Coating Matters column, is a fluid coating expert with experience and knowledge in the converting industry accumulated since 1996. Mark holds a Bachelor's degree in Chemical Engineering from the Univ. of Wisconsin-Madison and a Master's degree in Polymer Science & Engineering from Lehigh Univ. and a Juris Doctor from Hamline Univ. Mark is a technical consultant and CEO of Coating Tech Service LLC. He has worked in web coating technologies and chemical manufacturing operations and is a certified Six Sigma Black Belt trained in both DMAIC and DFSS disciplines. Coating Tech Service provides process troubleshooting and project management for precision coated products. Mark has extensive process knowledge in high precision coating applications including thin film photo voltaic, Li-Ion battery, and optical systems technology. Mark has been integral to new developments and technology that minimize product waste and improve process scalability.

Mark D. Miller, author of PFFC's Coating Matters column, is a fluid coating expert with experience and knowledge in the converting industry accumulated since 1996. Mark holds a Bachelor's degree in Chemical Engineering from the Univ. of Wisconsin-Madison and a Master's degree in Polymer Science & Engineering from Lehigh Univ. and a Juris Doctor from Hamline Univ. Mark is a technical consultant and CEO of Coating Tech Service LLC. He has worked in web coating technologies and chemical manufacturing operations and is a certified Six Sigma Black Belt trained in both DMAIC and DFSS disciplines. Coating Tech Service provides process troubleshooting and project management for precision coated products. Mark has extensive process knowledge in high precision coating applications including thin film photo voltaic, Li-Ion battery, and optical systems technology. Mark has been integral to new developments and technology that minimize product waste and improve process scalability.