Material Properties, Testing & Applications: Part 3

- Published: July 18, 2022

By Neal Michal, Principal, Converting Expert, LLC

Practical Applications with Real World Examples

This month we will complete the final installment of our three-part series on material properties. In April, we discussed tensile testing and how your material properties relate to common customer complaints. In May we discussed 12 aspects that will directly impact your tensile testing results. Today we will discuss how you can apply this knowledge to improve your process and deliver quality to your customer.

Convert to Intrinsic Units

Now that you have valid tensile data it is time to put it to work. Convert both elastic limit (EL) and ultimate tensile strength (UTS) to intrinsic units of force/ width: PLI (# force per inch of width) or newtons per meter.

For example, a common hygiene 15gsm Spunbond (SB) has an elastic limit of 0.55 PLI (96N/m) with an ultimate tensile strength of 3.5 PLI (613 N/m). As you monitor your process, con- sider these important values.

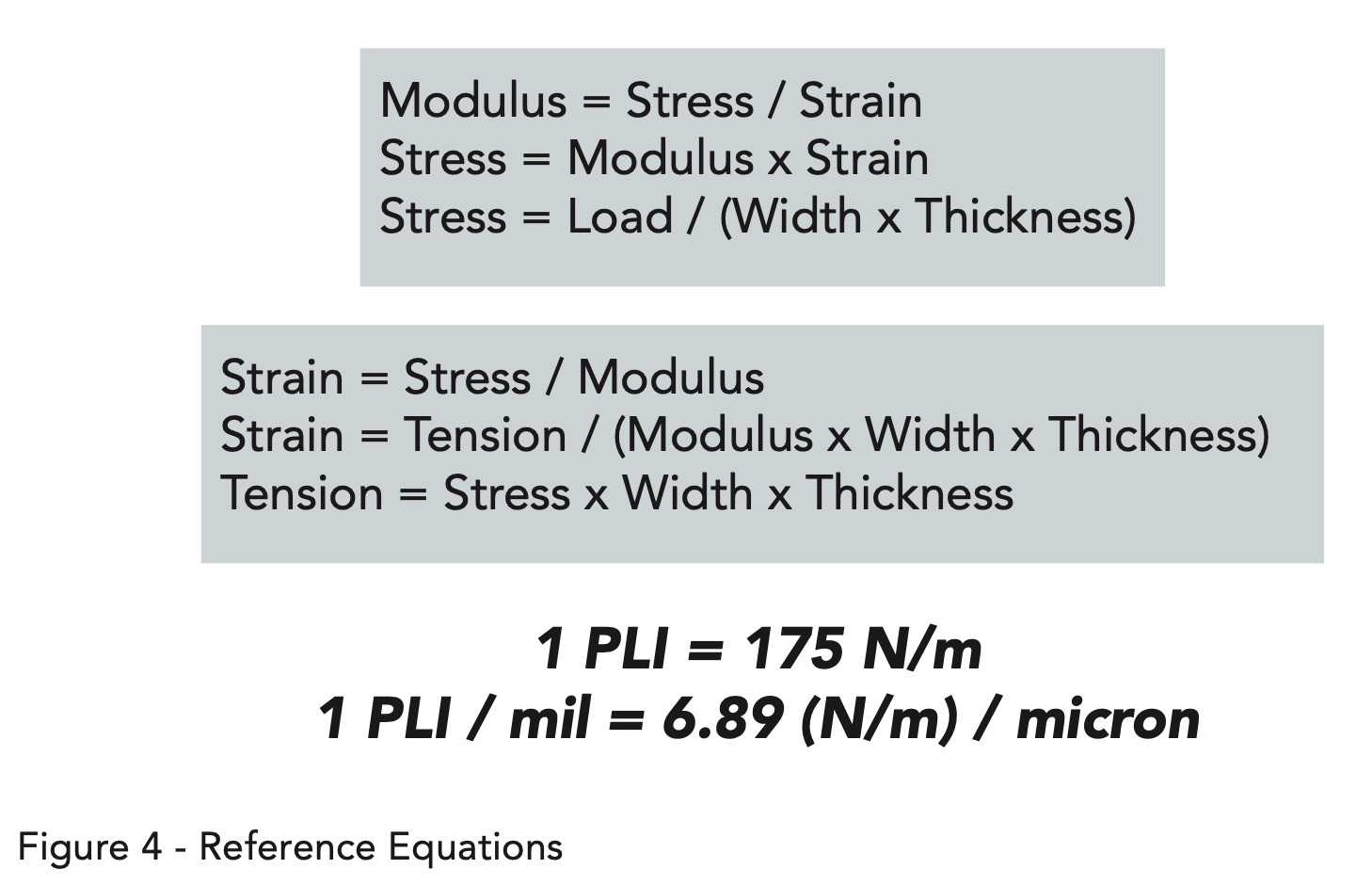

Set Target Tension

Recall the rule of thumb is to set tension to 10-25 percent of the elastic limit. If you export the load versus elongation data, you can determine the force at the elastic limit. If you only have data for elastic strain and modulus, you will need to calculate the tension at the elastic limit (EL) which is known as yield stress. Refer to Figure 4 for reference equations.

For example, Polymethyl methacrylate (PMMA) has a yield stress of 8,700 psi with a modulus of 300 ksi. If you elect to run at 25 percent of the elastic limit, set your tension to 218# for a 10” wide web with a thickness of 10 mil. (Target Tension = 8700 psi x 25% x 10” x 0.010” = 218#.)

Adjust Tension Based on Width

The benefit of calculating target tension in intrinsic units of N/m or PLI is that it facilitates adjusting tension based on web width. Assuming the same PMMA, you would set tension to 109# for a 5” web.

Adjust Tension Based on Thickness

Many processes run the same type of web but with different thickness. Take one more step to calculate tension based on force/ width/thickness. Recommended units are [N/m/μm] or [#/in/mil] where a ‘mil’ is 0.001.” For example, the recommended tension for PET is 9.5 N/m/μm (1.4 PLI/ mil). This approach will allow you to determine target tension for any web with the same physical properties.

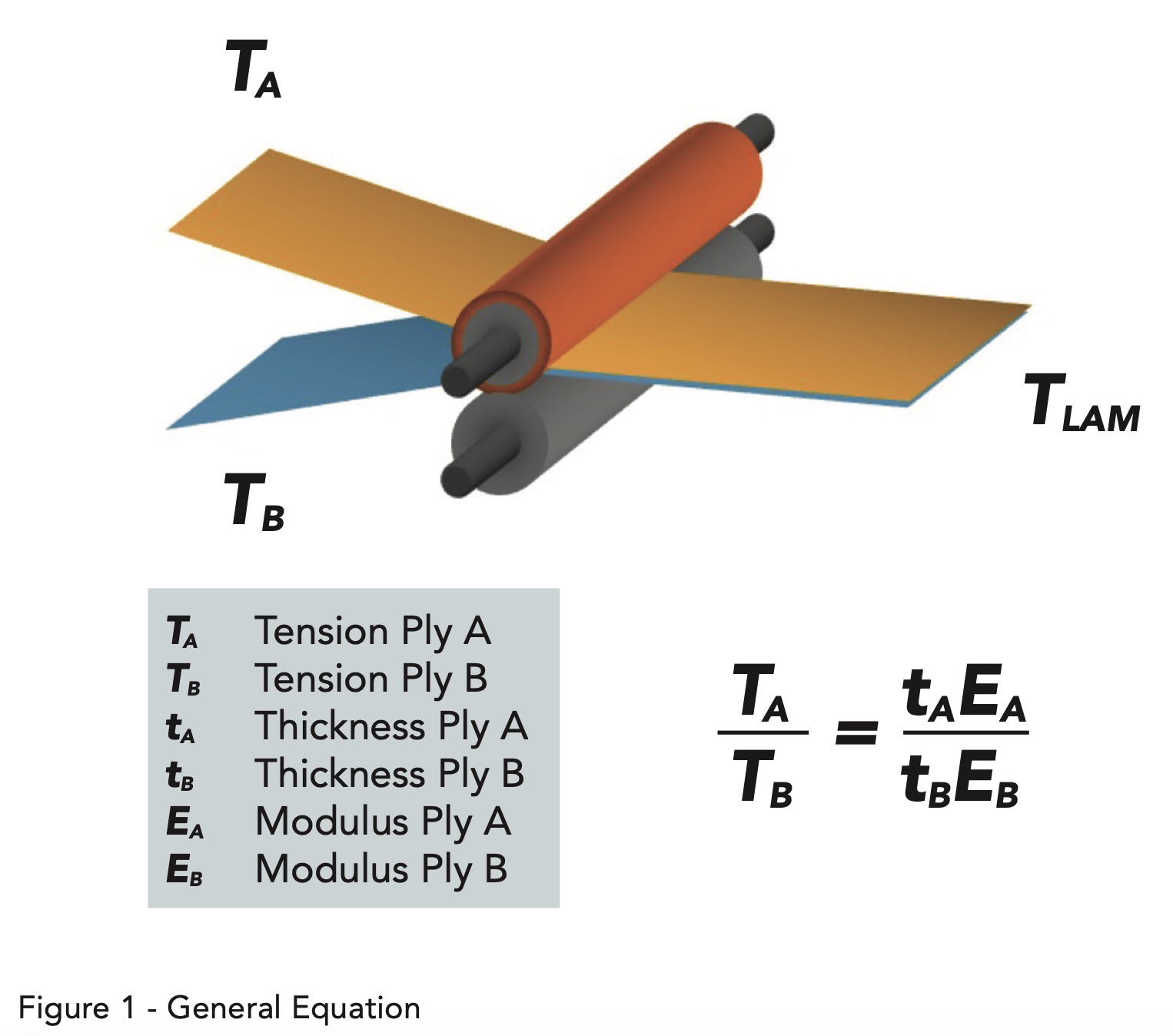

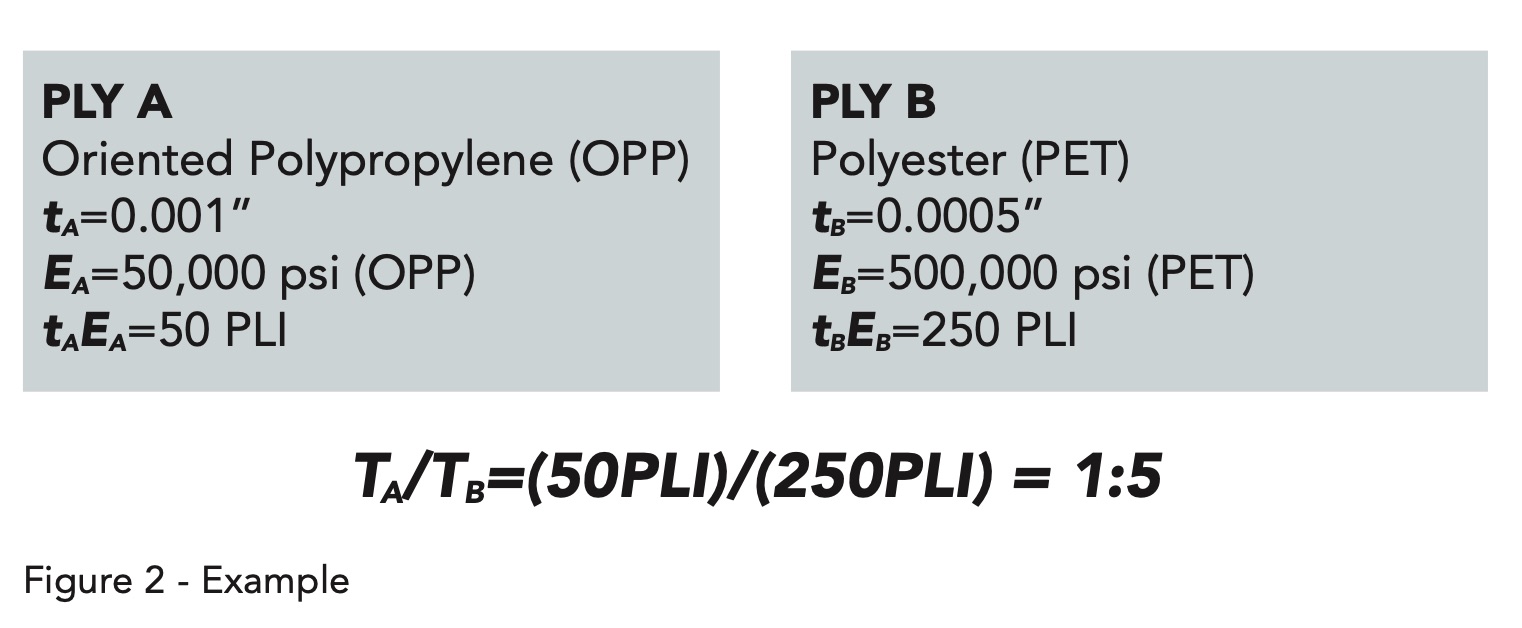

Correct Laminate Curl

Curl is a result of a strain difference between two plies in a laminate. Given thickness and modulus for two webs to be laminated, one must calculate the tension ratio to produce a flat laminate. Figure 1 shows the general equation; Figure 2 provides a sample calculation for PET and OPP. Despite being half as thick, the PET web should be tensioned five times higher than the OPP because of the 10:1 difference in modulus.

Understand Failure Modes

It is important to understand the failure mode for your most important grades. You will benefit from conducting the tensile tests personally. Watch the sample during the test to detect any visual clues as it is stretched beyond the elastic limit (EL). You may detect a visual defect long before the sample fails. For example, the Meltblown component in SMS is brittle compared to the Spunbond. Watch the coupons for pin holes to appear adjacent to the bond points. Make note of the tension when a visual defect occurs. Recently a customer was experiencing high waste on a face mask machine. The 10gsm SMS would weave for 60s after a zero-speed splice. They did not have any load cells installed. Pin holes were noted on the remaining butt roll. The tension spike was damaging the web. The initial decel rate was reduced for the first 50ms before returning to their normal settings. This minor change, based on the visual defect, virtually eliminated the high waste.

Exceptions to the Rule

Some materials require tensions that are outside of the recommended 10-25 percent rule of thumb. It is common to run nonwovens on high-speed converting lines close to the yield stress to overcome air drag and pull out any bagginess. The “rule” would suggest 0.06 – 0.14 PLI for the earlier 15gsm SB example. Actual good run settings are 0.45 PLI which is 81 percent of the elastic limit.

High modulus webs often run significantly lower tensions as compared to the “rule.” A recent customer winds a unique fiberglass laminate with a modulus of 30GPa (4.53 MPsi) and elastic limit of 2 percent; 10 percent of the elastic limit would be 87 PLI for a 10-gauge web (!). The winder runs best starting at 19pli with a linear taper to 12pli.

When in doubt, install a load cell to determine the best tension for your process. A calibrated load cell is an important addition to any web process.

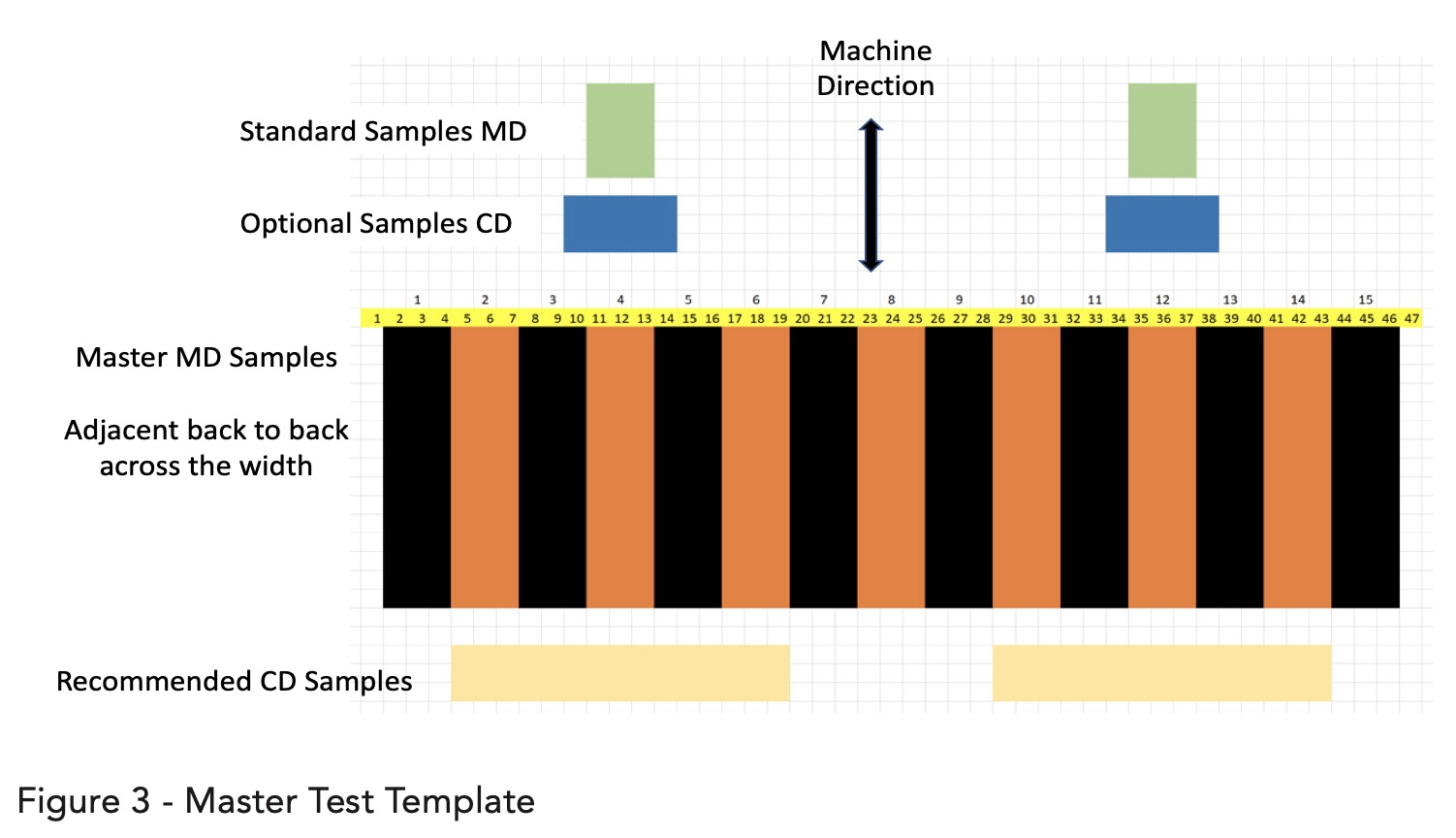

Develop Master Tests

Last month we discussed the benefit of larger length to width ratios (L/W) for the coupons you test. Online release tests often use small coupons with short L/W for convenience. High value webs benefit from the development of “master tests” using larger coupons.

Figure 3 provides an example for a 47” wide process. The green coupons represent “standard” samples at 3x5”. The black and orange samples (15 @ 3x15”) are taken back-to-back across the width of your process. The brown samples are recommended CD samples. You should weigh the master coupons before testing them.

This proven technique will allow you to document cross deckle basis weight profile and the associated tensile properties. It is ideal to conduct this test once a day. This high-resolution data will enable you to analyze your process health and to answer any future questions your customer may have.

Conclusions

Tensile tests are the last line of defense to insure you provide consistent material quality to your customer. Pay attention to the details. Thank you for following along.

About the Author

Neal Michal of Converting Expert is a well-known authority in web handling, process design and optimization. He worked with the Web Handling Research Center for 20 years. Currently serving as a technical advisor with AIMCAL, he can be reached at neal@convertingexpert.com or through www.convertingexpert.com.