New Food-safe Laminating Adhesives for Flexible Packaging

- Published: August 14, 2023

By Junya Aoyama, Researcher, Toyo-Morton, Ltd.

The global food market has doubled in size over the past decade due to worldwide population growth. Amid the global distribution of food products, flexible packaging materials will play an increasingly important role given that they are lightweight and their shelf-stability is high for long-distance transportation.

In addition, the circular design of food packaging materials is gaining greater attention as an approach to addressing marine plastic waste issues, global warming and countries’ toughening regulations regarding the import and export of waste. Flexible packaging materials could also assist the reduction of food loss by decreasing greenhouse gas emissions that lead to global warming.

Suppliers of materials throughout the supply chain are not just working to protect packaged contents by using flexible packaging and working to conform to increasingly strict regulations and standards, they are also striving to develop alternative packaging materials and solutions with greater environmentally-friendly advantages.

Laws and Regulations Regarding Food Contact Materials

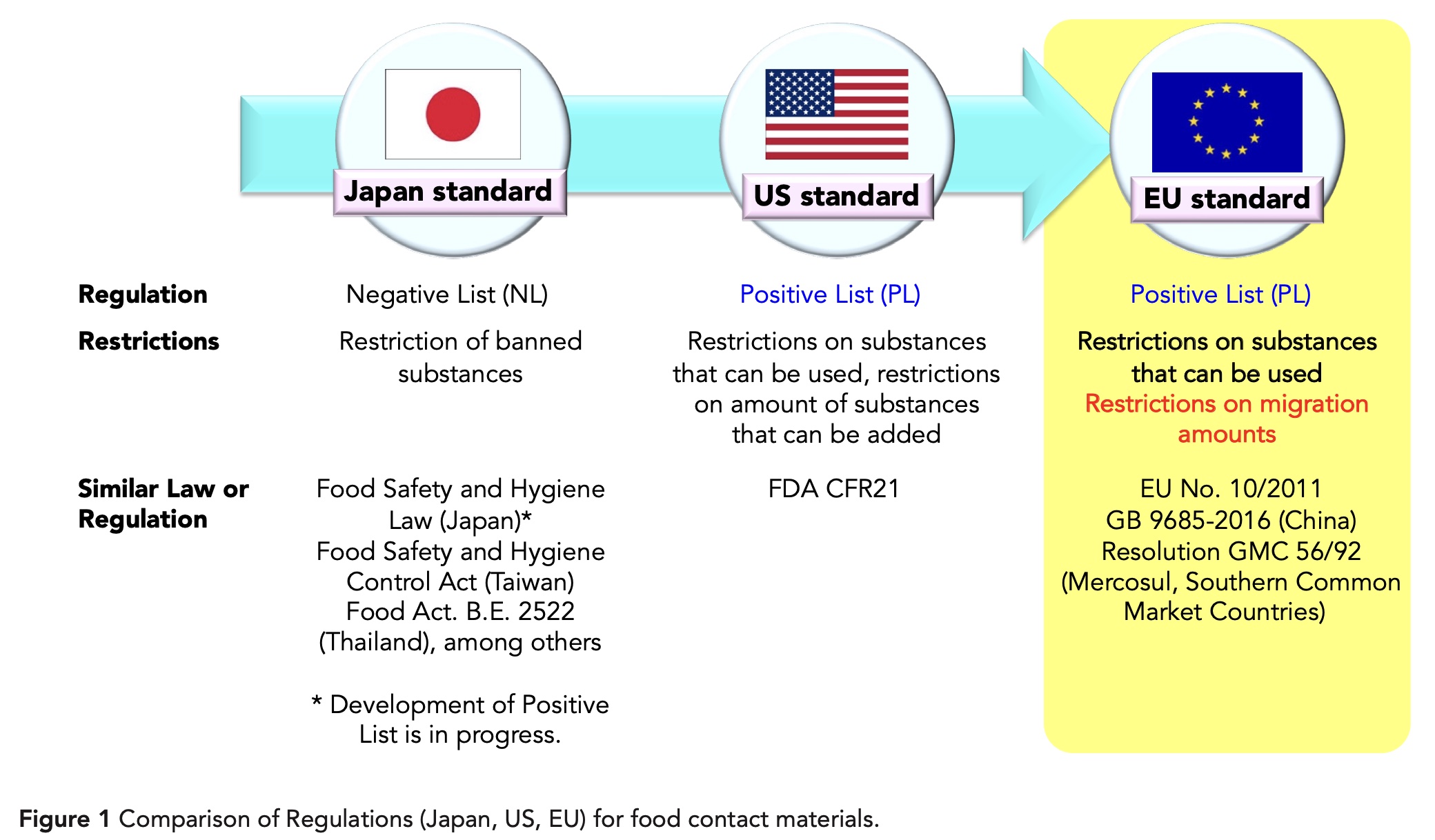

Let’s start by taking a look at past changes in key global laws and regulations regarding food contact materials and at recent regulatory trends in Europe (Figure 1).

In Japan, the Food Sanitation Act regulates and secures food safety. Laminating adhesives for food packaging applications are subject to the Voluntary Regulations on Adhesives for Food Packaging Materials formulated by the Japan Adhesive Industry Association. These laws and regulations provide negative lists (NLs) of substances that are, in principle, banned from use in food packaging. The U.S. has established a positive list (PL) of substances that may be used as packaging materials.

In the Japanese market, packaging materials are required to comply with both Japan’s Food Sanitation Act and the regulations formulated by the U.S. Food and Drugs Administration (FDA). Adhesives must satisfy the FDA 175.105, whereas adhesives for retort sterilization at 121°C and higher must meet FDA 177.1390.

The European Union (EU) has long been working to integrate within its member states the comprehensive laws and regulations regarding food contact materials (EC No.1935/2004). In 2011, the EU established the Plastics Implementation Measure (PIM, EU No.10/2011), which focuses on plastic materials and articles intended to come into contact with food.

Unlike the conventional regulations in Japan and in the U.S. that correspond to the amount of additive used, the PIM is unique in that it sets migration limits on individual substances on the list. This means that to comply with the EU regulations, manufacturers must not only create products from safe materials using safe methods but also make sure that substances actually do not migrate into food at levels that could harm.

In addition, since the aforementioned measure came into effect, an independent body assesses food safety and updates the list as appropriate. As a result, the EU’s safety standards are so highly objective that China (GB 9685- 2016), Latin American countries and others have adopted them in succession. They are quickly becoming the global standard.

New Food-safe Adhesive Products for Demanding Flexible Packaging Applications

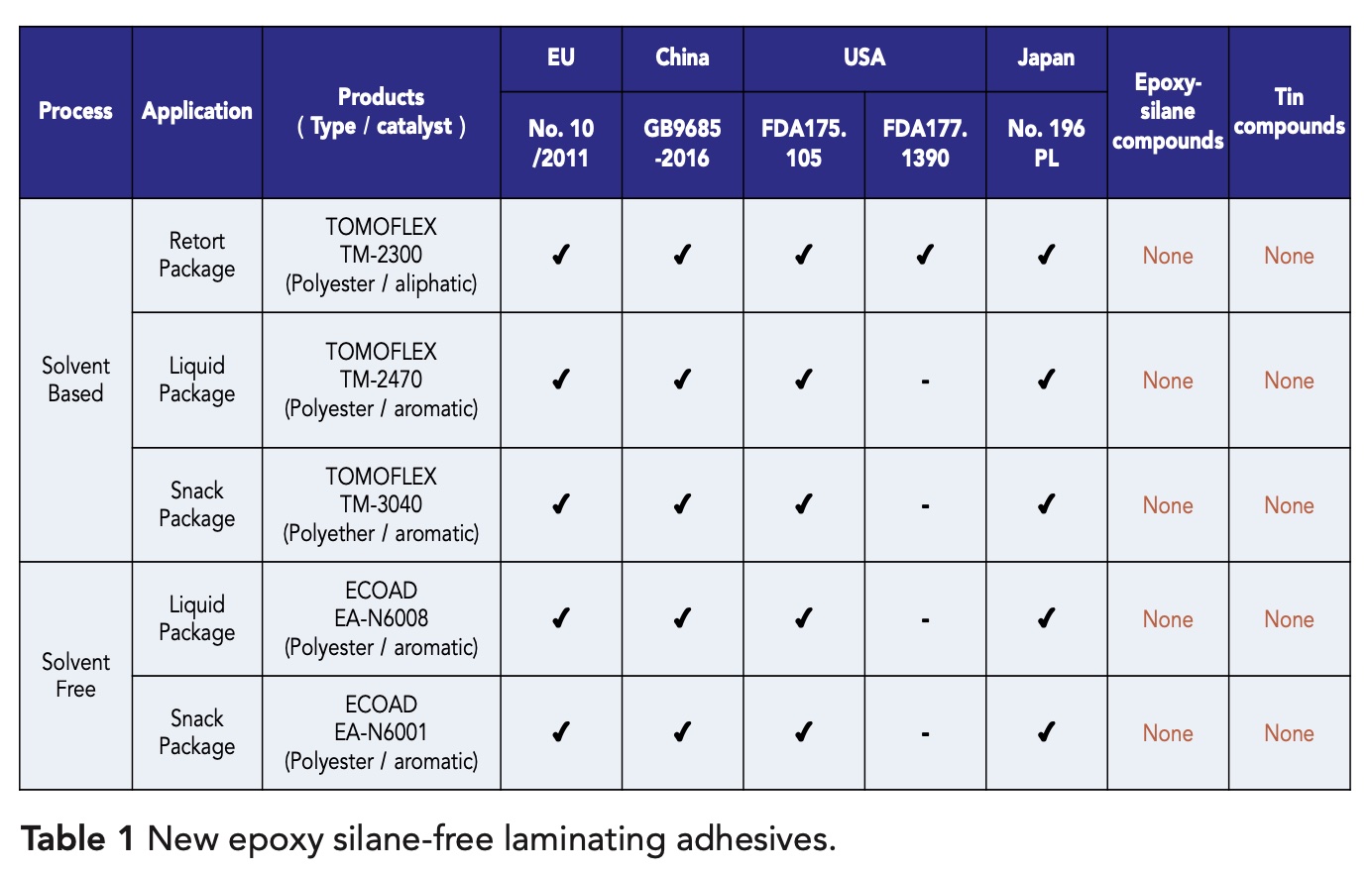

Given that global food exports are projected to rise, food packages need to fulfill the laws and regulations in different regions. Table 1 displays a lineup of the latest solvent-based and non-solvent-based laminating adhesives that are compliant with Japanese, U.S. and EU regulations.

Epoxy Silane-free Adhesives for Retort Packaging

Adhesives for retort packaging must be resistant to heat and water at the time of retort processing, resistant to the package’s contents and low in substances that can potentially seep into food. Packaging materials used in retort pouches to be processed at temperatures over 121°C must also meet FDA §177.1390 for enhanced safety.

To fulfill the aforementioned requirements without using the substances restricted by the EU (i.e., epoxy silane and tin compounds), new polymer synthesis technologies and interfacial adhesion technologies need to be applied.

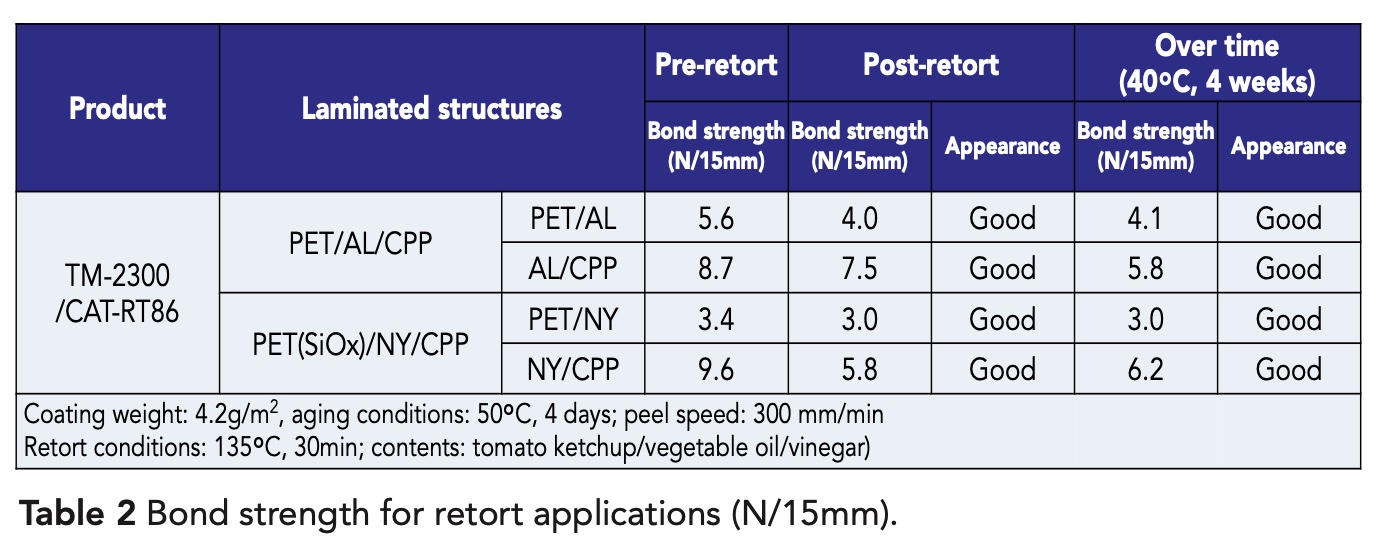

In response to this, adhesive manufacturers have been conducting research and development for these technologies and have developed new epoxy silane-free adhesive systems that prevent the laminated film from coming off (delaminating) during retort processing. As seen in Table 2, laminated structures using epoxy silane-free products show no significant deterioration in bonding strength after processing.

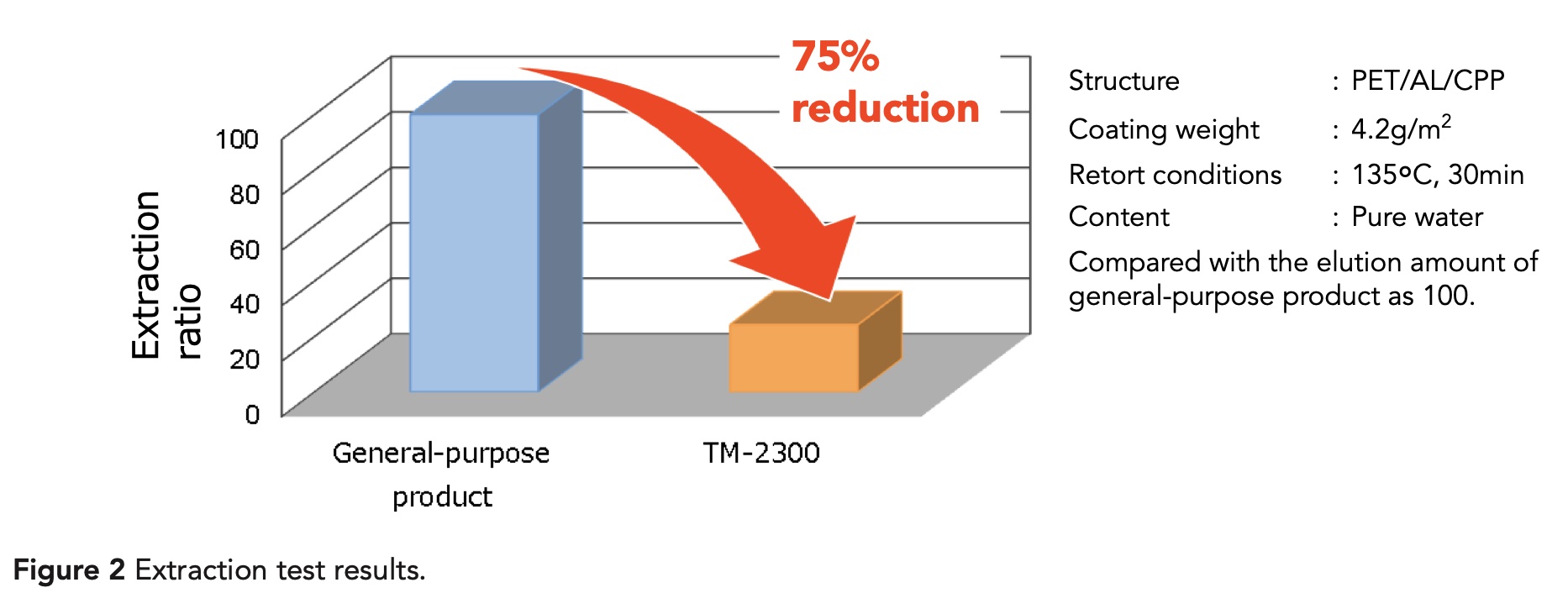

In addition, our proprietary synthesis process is very safe and paves the way for the design of polymers with very limited migration of adhesive ingredients into the contents of packages. For instance, a PET/AL/CPP laminate migration test involving retort processing at 135°C for 30 minutes demonstrated that the migration level is around 75 per- cent lower than the conventional product, minimizing its impact on the taste and flavor of the packaged content (Figure 2).

Adhesives for Liquid Packaging

The packaging of sauces and condiments often contains acidic products, including ketchup, chili sauce and spaghetti sauces. In laminated configurations that include aluminum foil or vapor-deposited aluminum film, adhesives need to have metal adhesion properties comparable with those for retort packaging.

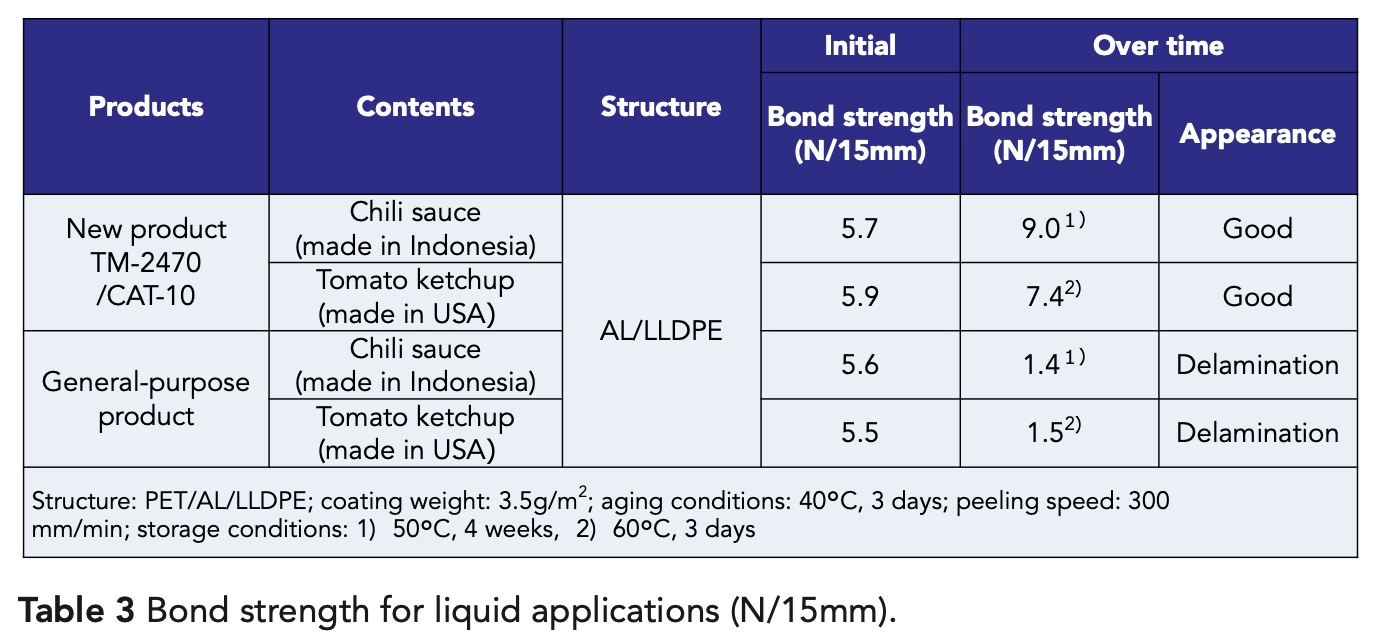

Table 3 shows that new interfacial adhesion technology effectively controls delamination and the deterioration of adhesive strength in comparison with general-purpose adhesives, even when the package contains highly acidic contents like ketchup or chili sauce.

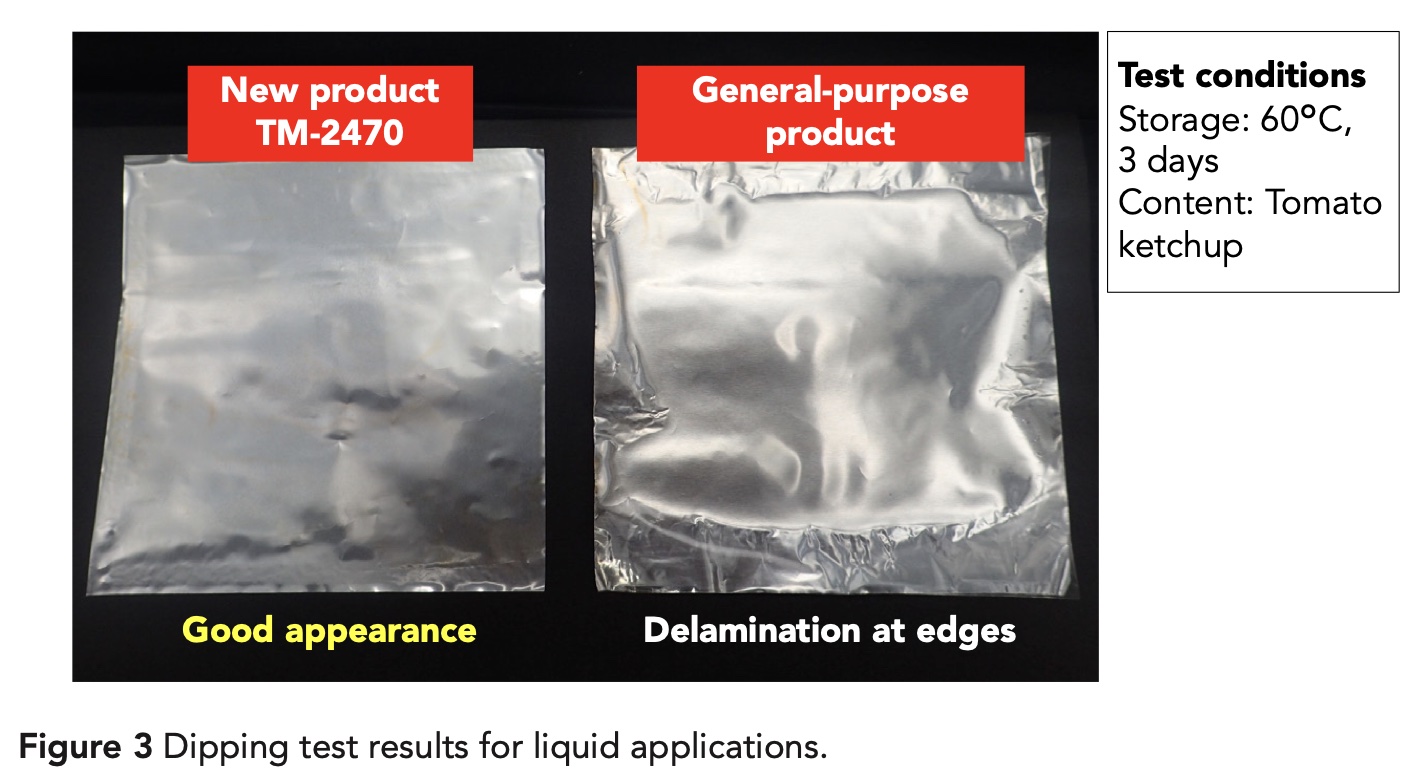

Of the many tests, the dipping test is a more rigid method of evaluating the package’s resistance to the aggressiveness of its contents. In this test, a sample cut from a laminated product is immersed in the package’s contents to check if delamination occurs.

A test sample of the metallized pouch structure produced using an aromatic polyester adhesive with catalyst was immersed in tomato ketchup at 60°C for three days. The delamination observed was limited in comparison with the test results of a general-purpose adhesive sample. Figure 3 shows the samples after the dipping test.

High Solids Polyether and Polyester-based Adhesives

Solvent-based adhesives have long been used in lamination processing. In fact, a huge amount of greenhouse gases are emitted throughout the solvent-based adhesive’s lifecycle of production, processing and incineration.

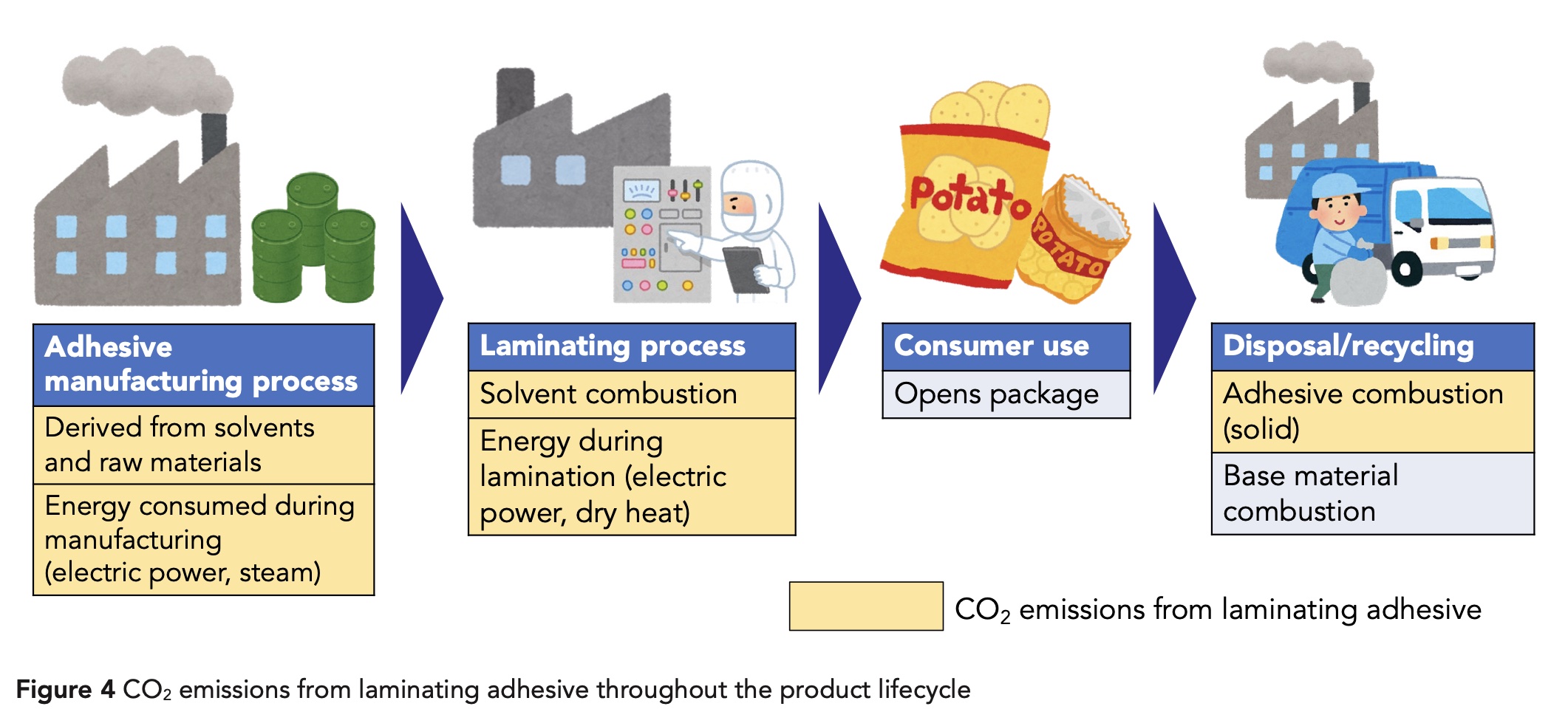

Addressing the emissions issue, newly released high solids polyether and polyester adhesives that are free of any regulated substances are proving effective in reducing solvent consumption for lowered CO2 emissions. In the lifecycle of laminated packaging, the laminating adhesive is responsible for CO2 emissions at the stages of manufacturing, lamination processing and the disposal of packaging materials (Figure 4).

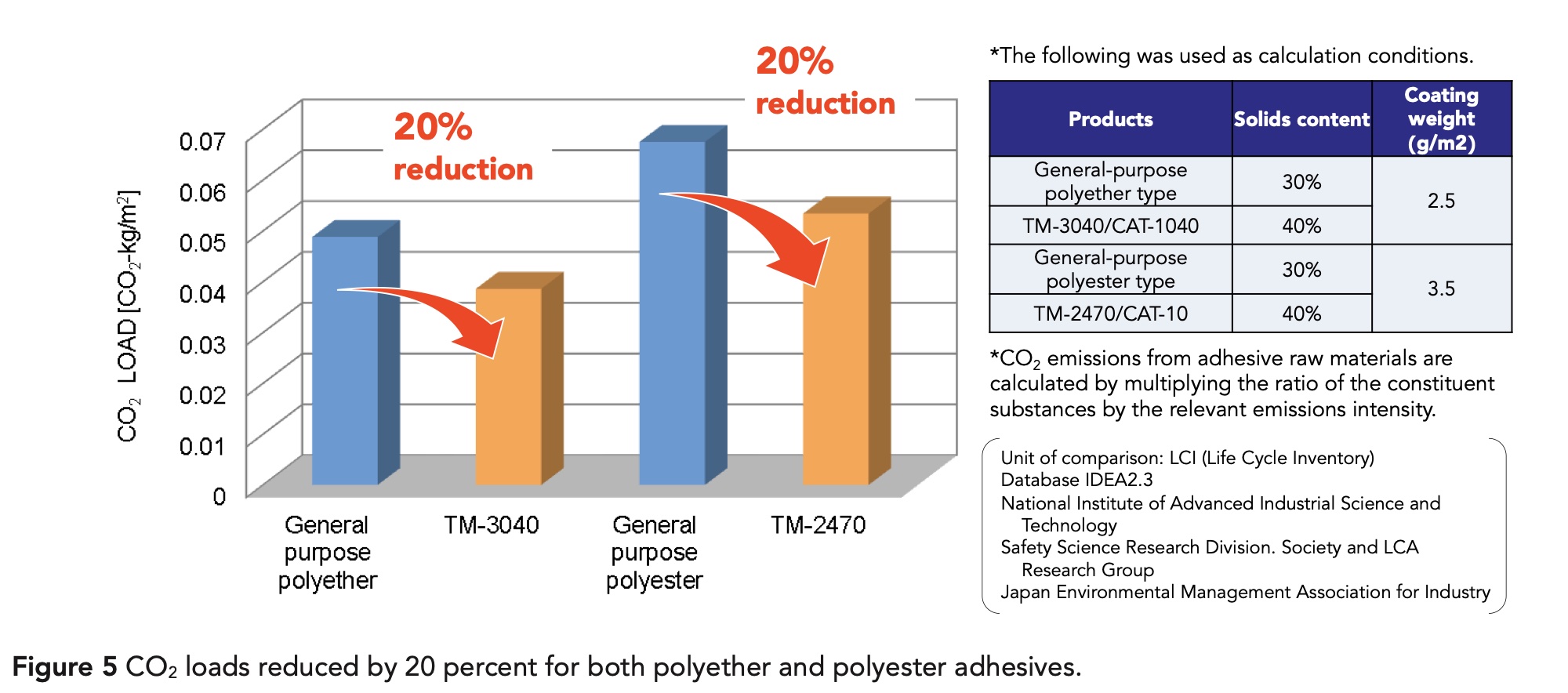

Figure 5 portrays a total sum of CO2 emissions from individual processes and estimated on the basis of the substances that compose the adhesive, their non-volatile content and the amount of application. An adhesive formulation containing 40 percent solids generates CO2 emissions that are around 20 percent lower than general-purpose products containing 30 percent solids. This increases food safety while reducing its environmental impact.

As demand for global food distribution grows, so do the calls for safer packaging material design. In Europe, materials that have been used for decades are now coming under scrutiny, while laws and regulations are expected to become increasingly stringent.

In recent years, many countries, including Japan, have started formulating regulations promoting circularity of plastic resources. As this trend is expected to continue for the foreseeable future, we expect to see more innovations in laminating adhesive design that help to not only advance a closed loop economy, but also maintain a high degree of safety and hygiene.

About the Author

Mr. Junya Aoyama is a researcher at Toyo-Morton, Ltd., Japan’s largest manufacturer of laminating adhesives. He is responsible for the design and development of adhesive solutions that are gentle to the health of humans and the Earth’s ecosystems. Toyo-Morton has been delivering highly reliable adhesive systems to the flexible packaging, electronic devices and other industrial markets for over 45 years. Learn more at toyomorton.co.jp/en/.