Sticking Points in Electronics Labeling

- Published: September 12, 2024

By Ralph Rhein, Technical Director, IDENTCO

In the electronic components sector, enhancing durability for labels and marking solutions exposed to harsh cleaning chemicals can be mission-critical. Cleanliness is critical in electronics manufacturing, particularly for applications such as printed circuit boards (PCBs) and other high-leverage components.

Proper best practices dictate rigorous cleaning procedures to remove contaminants before assembly, housing closure or complex integration. However, this rigorous cleaning program can be challenging for labels and marking solutions, which must tolerate exposure to strong cleaning chemicals without compromising readability or durability.

Here, a production paradox can ensue: In electronic components manufacturing, pristine cleaning and proficient labeling are each individually necessary ... but often mutually incompatible. Unfortunately, the former can significantly impact the latter, presenting an untenable "one or the other" scenario.

Fortunately, there are fixes — let's explore.

The Importance of Labels and Markings in Electronics

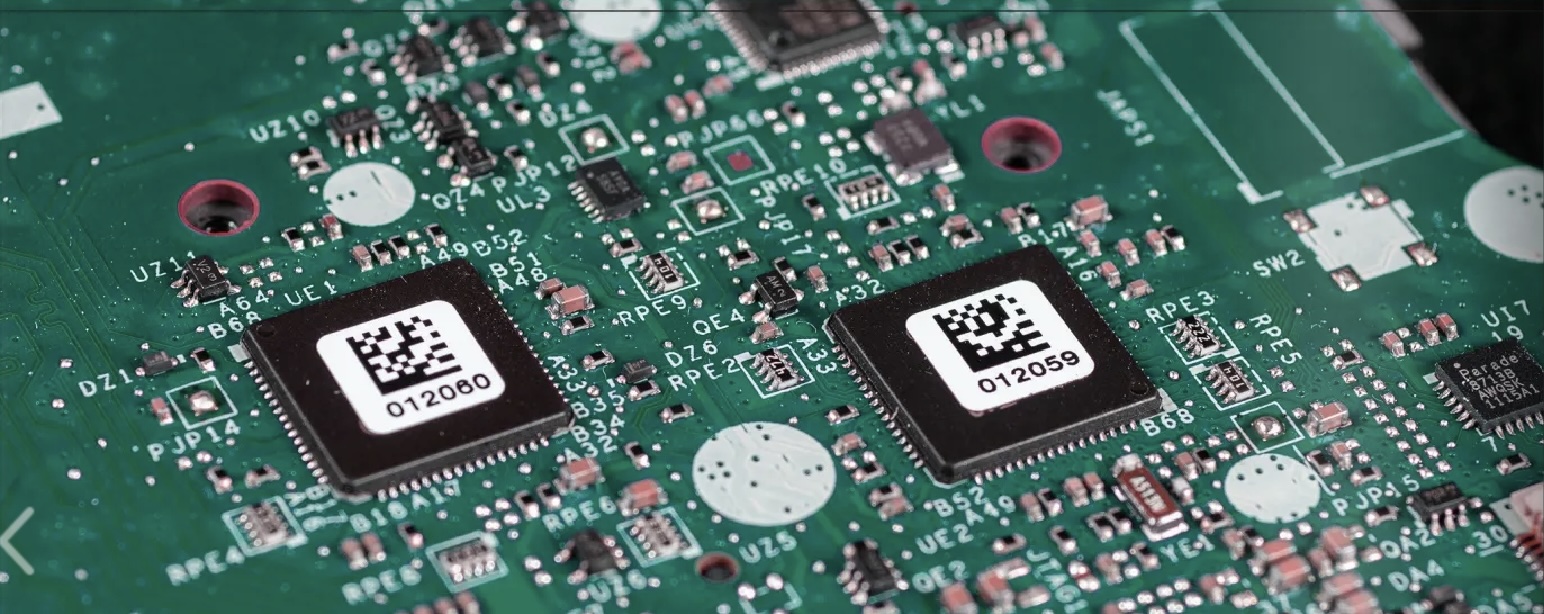

Labels and markings are crucial in electronic component identification, tracking and functionality. They include essential information such as part numbers, serial numbers, manufacturing dates, safety warnings and operating directions. Government and intra-industry mandates also must be abided: Accurate labeling is critical for compliance and traceability in heavily regulated industries such as automotive, aerospace and electronically-powered medical devices.

Suffice it to say that in environments where cleanliness is paramount, such as medical equipment or aerospace electronics, labels and markings must remain intact and legible even after exposure to aggressive cleaning agents. Failure to maintain label integrity can lead to misidentification, operational errors, compliance issues and compromised product quality and safety.

Challenges Posed by Harsh Cleaning Chemicals

Electronics manufacturing often involves harsh chemicals such as solvents, detergents and disinfectants in its cleaning processes. Such chemicals effectively remove contaminants like flux residues, soldering residues, oils and grease, ensuring the reliability and performance of electronic assemblies.

These effective yet necessarily harsh cleaning agents can lead to several unsavory issues for labels and markings. The most common pitfall is a dearth of chemical resistance. Many conventional label materials, such as paper-based or standard adhesive labels, are susceptible to degradation when exposed to aggressive cleaning agents. This can result in smudging, fading or, in the most severe instances, complete obliteration of the printed information.

Adhesion assurance presents another noteworthy obstacle. Harsh chemicals can weaken the adhesive bond between the label and the substrate, causing labels to peel off or detach during the cleaning process or subsequent handling. Similarly, legibility issues are another potentially purpose-defeating problem. A harsh cleaning process may blur or distort printed label information, making it difficult to read, scan or interpret critical data.

A subset of each of these categories is general physical deterioration or damage; labels and markings may suffer any number of nicks, scrapes and other injuries due to component cleaning procedures. For example, abrasive cleaning techniques like scrubbing or high-pressure spraying often result in tearing, wrinkling or losing the label altogether. Here, even when the overall functionality of the label isn't affected (albeit barely), the result can be wary customers for whom perception becomes a business-centric reality. Electronics manufacturers want labels that pass cleaning tests with flying colors, not by the skin of their substrates.

Innovative Solutions for Enhanced Durability

To address the challenges posed by harsh cleaning chemicals, some prominent manufacturers have developed specialized labeling and marking solutions designed to withstand these environments. These solutions incorporate advanced materials, adhesives, and printing technologies to ensure durability, chemical resistance and legibility.

The keystone of these solutions is the emergence and proliferation of chemical-resistant labeling materials. High-performance label materials, such as polyimide or polyesters, offer superior resistance to a wide range of chemicals, including solvents, alcohols, detergents and washing/cleaning technologies from industry standard providers (like Kyzen and Zestron). These materials maintain their integrity and legibility even after prolonged exposure to harsh cleaning agents.

Of course, this next-generation breed of chemical-resistant substrates must be paired with more durable adhesives. Pres-sure-sensitive adhesives formulated with enhanced chemical resistance properties ensure secure bonding between label and substrate, preventing detachment or lifting, even under harsh cleaning conditions.

Printing techniques also have evolved to meet the moment. Practices such as thermal transfer printing and digital barcoding allow for automated tracking and inventory management, reducing the reliance on manual data entry and minimizing the risk of labeling errors or misplacement during the cleaning process. Notably, labels offering options for on-demand thermal transfer printing of variable information are a plus for electronics companies incorporating serialization and/or anti-counterfeiting coding into their production practices.

Conclusion

In the demanding electronics manufacturing environment, where cleanliness is crucial for product reliability and performance, labels and markings must withstand exposure to harsh cleaning chemicals without compromising functionality or legibility. Innovative solutions incorporating chemical-resistant materials, durable adhesives, advanced printing technologies, and protective coatings ensure that labels and markings remain intact and readable, even after rigorous cleaning processes.

Encouragingly, as the technologies of durable labeling solutions have continued to progress, they've also become more cost-effective, making the inherent return on investment realized by substantially reduced product failure all the more enticing. By investing in these enhanced labeling solutions, component labeling manufacturers can improve product quality, compliance and traceability in high-leverage electronics applications, better ensuring customer satisfaction and a perpetually viable pool of new business in the burgeoning electronics components segment.

About the Author

Ralph Rhein is the Technical Director for IDENTCO, a designer, manufacturer and supplier of labeling solutions for several demanding industries, including automotive components, electronics applications, industrial machinery and tools, and commercial transportation. The company specializes in exactingly engineered labels, ribbons, applicators and printers for product tracking and tracing, branding, compliance and identification. Learn more at www.identco.com.