Optimizing Costs

- Published: December 01, 2006, By Ann Hirst-Smith, AWA Alexander Watson Assoc.

Part 1 | Part 2 | Part 3 | Part 4

Optimizing Costs

To help label manufacturers protect themselves from the rising price of the platinum metal used in release coating catalysts, Dow Corning developed a line of low-platinum silicone release coatings that mirror the performance of established platinum-catalyzed solventless systems. They employ proprietary polymers and crosslinkers that enable lower platinum usage.

According to Norm Kanar, Dow Corning Americas area market manager for release coatings and pressure-sensitive adhesives, “Our Advantage Series of low-platinum, solvent-free coatings has established a solid global track record of proven performance. The system has demonstrated its effectiveness in more than 60 coating operations in 23 countries.”

Dow Corning has introduced eight additional products including coating, crosslinker, and release modifier choices. They give label makers more ways not only to reduce their need for costly platinum catalyst but also to improve processing and performance factors that contribute to cost optimization.

Good Cure, Anchorage & Compatibility

Lower-cost substrates and adhesives are one way to lower material costs significantly. However, now it is demonstrably possible to do so by reducing the amount of platinum required to cure a release coating.

The polymer and crosslinker architectures in the new series of products reportedly provide remarkable cure at very low platinum levels. As an example, Syl-Off SL 800 coating cures well at platinum levels as low as 25 parts per million when used with its designated crosslinker, according to Dow Corning.

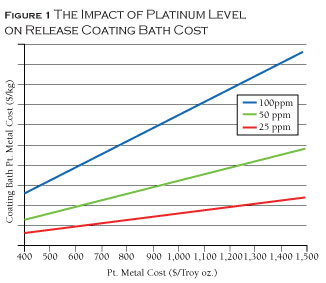

Figure 1 illustrates the effect ultra-low platinum products can have on platinum-related release coating bath costs. The products also are said to offer excellent anchorage to many different substrates and are compatible with a variety of adhesives. This gives manufacturers greater freedom in selecting cost-effective laminate components.

Low-Temperature Cure

The ability to cure coatings at lower temperatures can lower energy costs. It also reduces the need for paper re-moisturization and minimizes the potential for quality defects caused by prolonged exposure of the liner to higher temperatures.

The new products also feature advances in anti-mist technology. As a result, these coatings can be applied at extremely high speeds with very good anchorage and coverage and no visible mist at the coating head, Dow Corning reports.

Faster Silicone Coating

Time is money. Nowhere is that philosophy more evident than in today’s pressure-sensitive industry. Kanar says some of the fastest industrial release coaters currently are applying silicone coatings at speeds greater than 800 mpm, and trials are being conducted at speeds in excess of 1,000 mpm.

In September 2005 Kroenert held a high-speed coating trial at its Technology Center in Hamburg, Germany. The Dow Corning Advantage Series was used to set a new world record for siliconizing paper: 1,600 mpm. (See PFFC November 2005, p47, for more information.)

Faster Converting & Dispensing

According to Kanar, the new products feature flatter release profiles (easier release) at high stripping speeds than other very-low-platinum release systems. Ultimately, this supports faster label converting and dispensing.

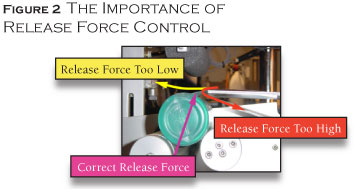

The ability to regulate release force is essential to the success of high-speed dispensing operations. If the coating’s release force is too low, the label may “fly off” the backing. If the release force is too high, the label could tear during transfer or fail to dispense (see Figure 2).

To combat these problems, Dow Corning has developed high-efficiency release modifiers that enable manufacturers to increase release force as needed to meet specific stripping and dispensing requirements. Because these modifiers reportedly are so efficient, it is possible to achieve higher release with less modifier.

The high price of platinum is set to stay. Without compromising release characteristics and processing, new products are available that are designed to help reduce the release liner industry’s costs through low misting, good cure, robust anchorage, and a high-efficiency release modifier.

SUPPLIER INFO:

Dow Corning—PFFC-ASAP 301. dowcorning.com/psi

Kroenert Corp.—PFFC-ASAP 302. kroenert.com

Ann Hirst-Smith is an associate of AWA Alexander Watson Assoc. and an independent journalist specializing in the fields of packaging and labels, self-adhesive materials, and large-format graphics.

Part 1 | Part 2 | Part 3 | Part 4