Wound Roll Mechanics: Part 1

- Published: May 11, 2022

By Neal Michal, Principal, Converting Expert, LLC

This is Part 1 in a four-part series regarding winding, with this month’s focus on wound roll mechanics.

Winding – Introduction

Winding is an integral process in the manufacturing and converting of nearly all web materials such as paper, film, tissue, nonwovens, foils and laminates. Wound rolls are the most convenient and economical form of storage and transport for web materials.

Center winders are common for film. The addition of a nip roll will allow higher speeds. Surface winders are common for building large rolls. The addition of center wind assist allows lower nip load for delicate high loft webs. Two drum winders are common for high-speed tissue and paper. Belted reels can wind tissue rolls to large diameters with consistent thru roll properties.

Wound rolls store web materials compactly without folding or cutting. Wound rolls are a form of compressed packaging. A roll that has been wound firm enough for routine handling will have internal stress and strain that will determine your aged thru roll properties and the potential for wound roll defects.

Three Principal Stresses

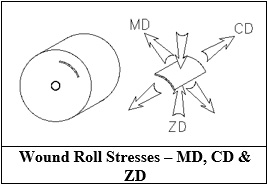

Every layer of material stored inside of a wound roll will experience three stresses: MD, CD and ZD. The shape of these stresses thru-roll is known as the wound roll structure.

- MD — Machine direction stress in the plane of the web. Often described in terms of strain.

- CD — Cross machine direction stress in the plane of the web. Often ignored.

- ZD — Stress perpendicular to the plane of the web. Also referred to as Interlayer pressure.

This series will focus on MD and ZD stress. CD stress is only important for webs with high Poisson.

Wound Roll Structure

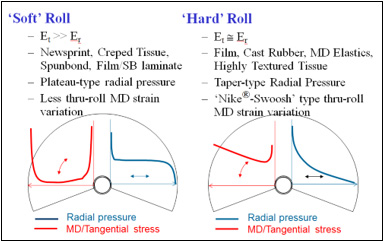

The wound roll structure describes the shape of MD and ZD stress profile. There are only two types of wound roll structures: “Soft Roll” and “Hard Roll.” The naming convention “Soft” versus “Hard” is not completely satisfactory. This is not to be confused with a qualitative assessment of how hard a roll is wound. t really deals with the relationship between the MD modulus versus the ZD modulus of the web. (Refer to my previous series that describes material testing.) If the MD modulus is significantly greater than the ZD the roll structure is described as a “Soft Roll.”

There is significant compliance in the ZD direction. The web can be compressed in the ZD direction easily. Examples of materials that fall into this category are Creped Tissue, Spunbond and Film/Spunbond laminates.

If the MD modulus is approximately the same as the ZD modulus the roll structure is described as a “Hard Roll.” In the ZD direction the web is fully compressed. This is often known as a fully compressed roll structure. Examples of materials that fall into this category are Film, Cast rubber, MD Elastics and Highly Textured Tissues.

Impact of Wound Roll Structure

We will first discuss ZD stress which is often referred to as Interlayer Pressure (ILP). (Refer to the graph.)

A soft roll will display an S-shaped ILP (blue line). ILP peaks at the core and will have a wide plateau through the middle of the roll. This is why caliper-sensitive materials like tissue will be compressed up to 60 percent at the core with 25 percent compression through the wide plateau.

A hard roll structure like film will have much greater ILP close to the core. High ILP is the root cause for film blocking. It also restricts the buildup ratio (Roll OD / Core OD) for a roll of film.

It is a common misbelief that the MD stress (or strain) thru roll will be the same from the outside of the roll to the core. The outer layers of the roll compress the inner layers. This interaction will result in one of two unique MD stress thru roll profiles as shown (red line).

For soft rolls the outer third of the roll length will compress the inner two thirds. This is graphed as a U-shaped profile. It is common for the material inside the plateau region to be close to zero MD stress. If the roll is wound too tight the layers may buckle which can cause CD Buckles.

Conversely a hard roll will have a Nike™ Swoosh profile for stored MD strain. All of the web stored in the roll is under tension. The resulting MD strain profile is the root cause of registration shift for printed film rolls.

Bigger Rolls

Longer rolls with more material can provide cost savings. The addition of more material on a soft roll does not make a big effect on the interlayer pressure or stored MD strain. This is why tissue-base sheet rolls are often 10 foot in diameter. Conversely, the addition of more web material on a hard roll will have a dramatic effect on the interlayer pressure and stored MD strain for a hard roll. That is why most film rolls are limited to 30-inch diameter.

It is important to know what type of wound roll structure you have in order to make improvements to your delivered quality.

In our next article, we will discuss how you can document your wound roll structure and the importance of tension, nip and torque on your winding process.

ABOUT THE AUTHOR

Neal Michal of Converting Expert is a well-known authority in web handling, process design and optimization. He worked with the Web Handling Research Center for 20 years. Currently serving as a technical advisor with AIMCAL, he can be reached at neal@convertingexpert.com or through www.convertingexpert.com.