In the Spotlight: MAMATA

- Published: September 10, 2021

With an installed base of nearly 4,800 machines in more than 78 countries, Mamata is a globally known manufacturer and exporter of plastic bag / pouch making machinery. The company designs systems that are fit for today’s market needs, providing machines with improved flexibility, greater productivity, and operator friendliness, giving its customers an edge in today’s competitive market.

With an installed base of nearly 4,800 machines in more than 78 countries, Mamata is a globally known manufacturer and exporter of plastic bag / pouch making machinery. The company designs systems that are fit for today’s market needs, providing machines with improved flexibility, greater productivity, and operator friendliness, giving its customers an edge in today’s competitive market.

Recently, Mamata took some time to answer a few questions from PFFC about what makes them stand out.

What two or three converting machines do you want our audience to specifically know about, and what makes them desirable?

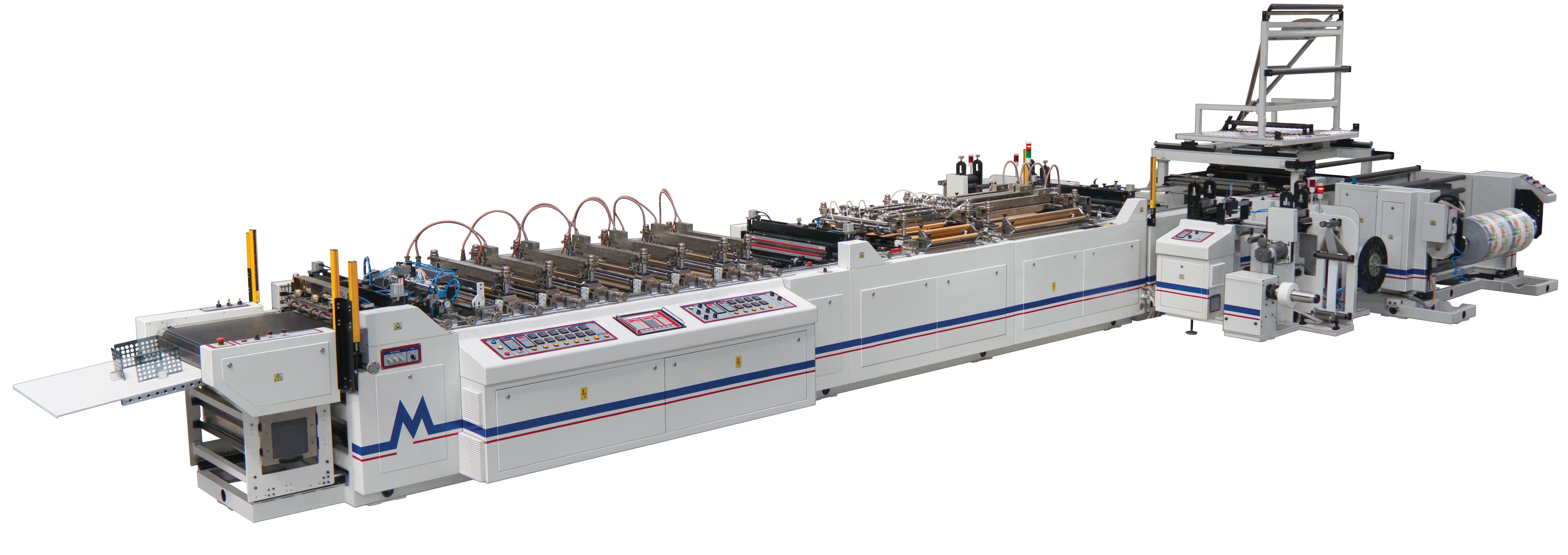

Mamata’s entire product range is desirable to the audience but if I have to pick and choose three machines, I would pick our pouch makers, Wicketers, and universal bag machines. The amount of flexibility and versatility it offers, no other machine can match that. E.g. our universal machines offers under 10 minute changeovers from side seal to bottom seal or twin seal capability. Our Wicketers offers best outputs on zipper Wicketed bags, square bottom bags, eCommerce bags, etc. The pouch machines we offer are unique in sealing technology, which allows us to run a straight mono-material PE film with same ease as a laminated film and make a stand-up or side gusseted quad seal or flat bottom pouch.

What exciting things have you done with some of your bag and pouch machines for a customer in the last year?

We recently delivered a flat bottom pouch machine that is able to run a mono-material PE film and make a flat bottom pouch with or without zipper. We also enhanced speeds on our Wicketers in 2020 from 350 cpm to 425 cpm. Also recently, we introduced our new highspeed bottom seal machines to the converting fraternity giving them option to replace their old systems and enhance their productivity and add flexibility to make a wide variety of bottom seal bags.

Have you seen your machines opened up some new vertical markets if so, which ones?

We opened up the vertical of heavy-duty bottom seal bags with our new bottom seal machines. Our ability to run all PE film structures has opened up the avenues of flat bottom pouch market as well as standup pouch market. With increase of eCommerce business, we sold our Wicketers and Universal machines for making eCommerce mailer bags.

How is Mamata addressing sustainability concerns with its machinery?

We have been working in this area since 2004. We were the first company in the converting industry to run a PE recyclable film on our pouch machines and show the world that we can offer you solutions for the sustainability and recyclability concerns of the industry. Today, Mamata machines are perhaps the only systems available in the industry that can run mono-material recyclable PE films without any special coating or treatment and convert into a pouch. When we introduced our horizontal form fill and seal pouch machines in 2011, we were the first and the only company to show the capability of running PE recyclable films on a packaging line.

The supply chain has changed quite a bit over the last year, how is this directly affecting Mamata and what processes does the company have in place to help its customers address this issue?

We are aware of disruptions in supply chain from Europe, China, other parts of the world. We are therefore building higher inventory to meet demand of the market and this has resulted in higher inventory cost.

Have new developments in machinery been developed as a direct effect of the changing needs of customers in recent years?

Our design and development program always works hand-in-hand with its converters and have come up with the solutions to address changing market needs. Any upgrade or enhancement made on our existing product range or new introduction of product is a result of inputs from our converters, packagers and the changes happening in the market. This is what has made Mamata grow its footprint to over 85 countries globally and has more than 5000 machines working in a span of 31 years.

What new innovations can we anticipate in the near future from Mamata?

Mamata continues to work towards enhancing its existing machines to meet the current and future needs of converting industry. Our Wicketers are now rated at 425 CPM mechanical speeds. We upgraded our pouch machines to 250 cpm mechanical speeds. We enhanced our split draw roll machines to do eCommerce bags in two lanes at high speeds with increasing demand of online retail shopping. With sustainability and recyclability in the center stage now, we have seen a shift in the PET food industry, fertilizer, mulch and garden related packaging. Mamata introduced the new high bottom seal bag machines that allows heavy duty packaging to convert these bags using recyclable PE/PE films instead of PET/PE laminates.