HOW TO: Mark Defects Safely and Automatically

- Published: November 07, 2022

Let’s face it. Despite your best efforts to eliminate it, scrap happens. And when it does, you need to always know where it happened so you can find and remove it before it reaches your customer.

Maybe you insert a slip of paper into the winding roll, or hand apply a pressure sensitive label to the moving web, or possibly use a felt pen. These too often used manual practices are extremely dangerous and result in countless injuries. As a result, many lines are now equipped with guarding and interlocks making it impossible for operators to access the moving web.

Not only is hand marking webs an unsafe practice, but it is inaccurate and costly as well. By the time a defect is noticed and the web is hand marked, yards of defective product can pass, resulting in wasted time and product when removing the bad material downstream.

Maybe you “remember” where scrap is with digital roll maps which are used to locate and identify scrap. These systems work well until material is removed from the roll. If you slab off damaged material on the outside of the roll or you remove scrap within the roll, some physical marker is required to then resynchronize with the roll map.

So, how can one safely and accurately mark defects, and also track scrap? Automatic web marking offers a solution.

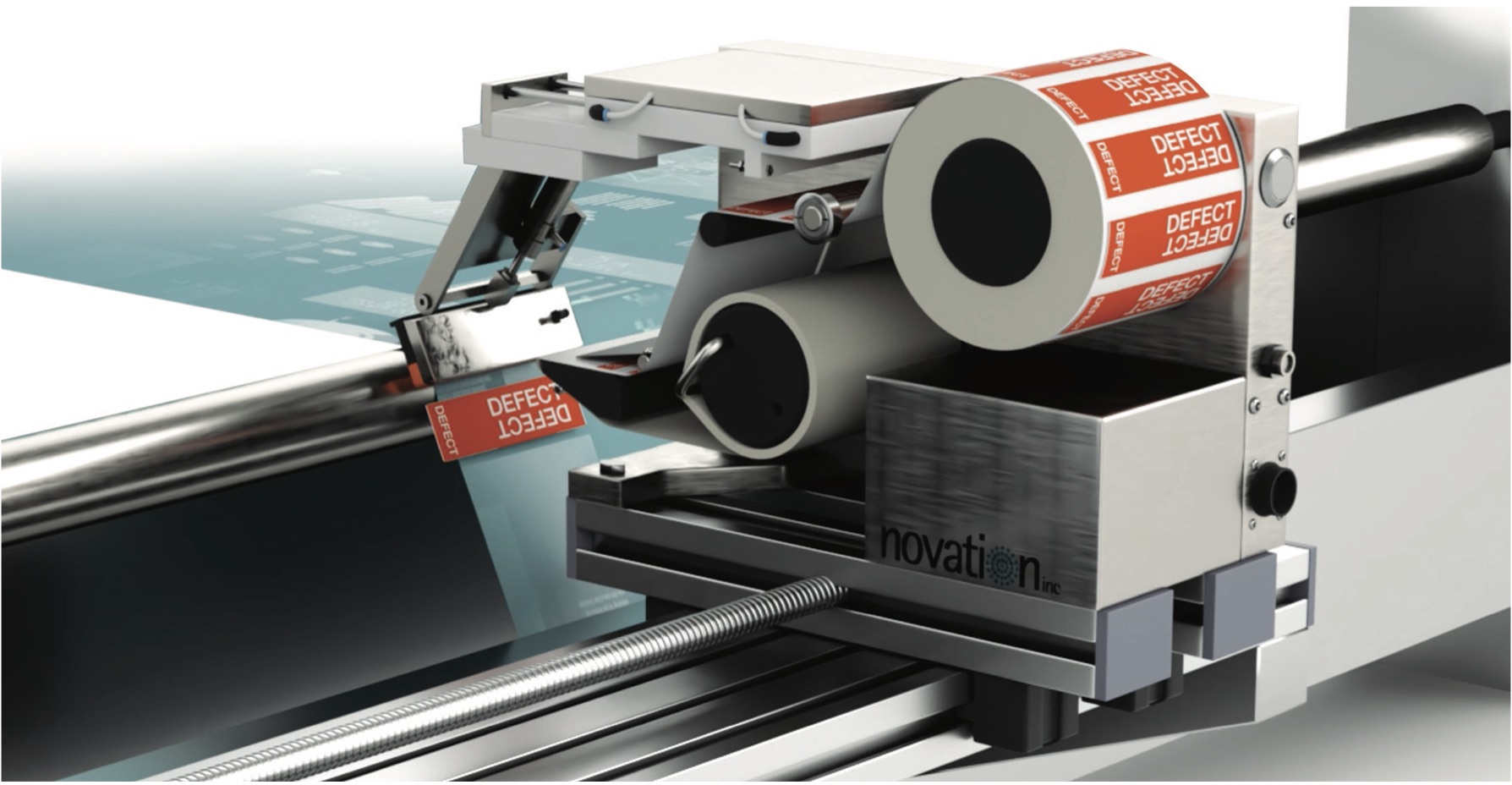

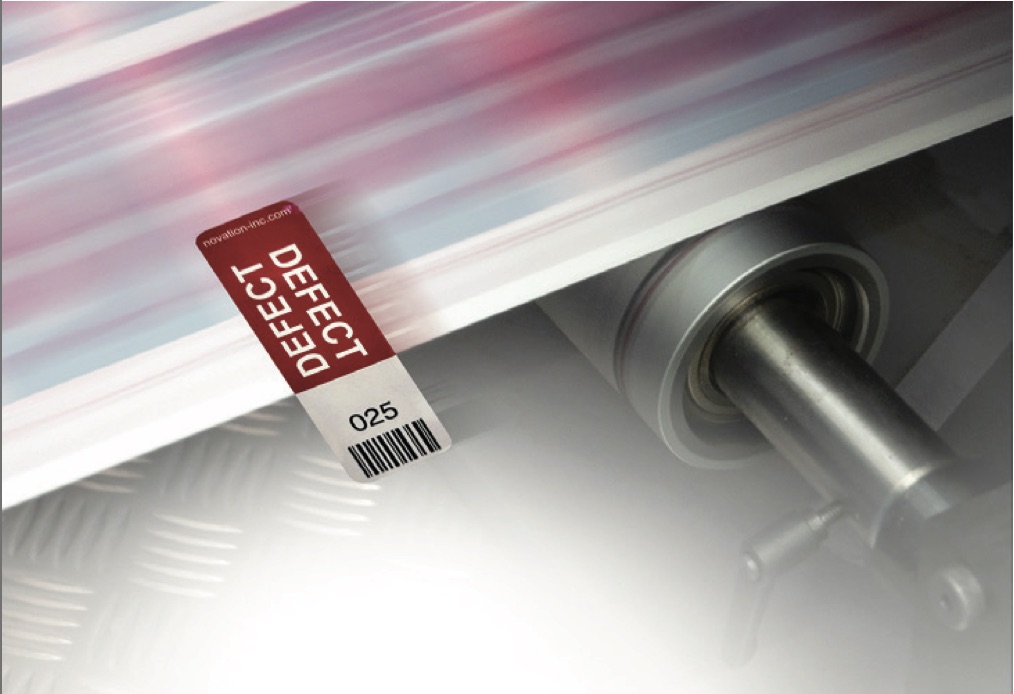

Novation’s WebFlaggers safely, accurately, and automatically place pressure sensitive labels on webs at any process speed. A portion of the label has no adhesive and hangs off the edge of the web like a “flag” making it visible in wound rolls. They can be triggered manually, from inspection systems, or from any machine signal.

WebFlaggers can also be combined with digital roll mapping to solve the resynchronization problem mentioned above. Novation’s AF3 WebFlagger can be integrated with most all roll mapping systems as well as their own.

Novation’s ScrapTracker system applies pre-printed, numbered, bar-coded flags and creates roll maps with each flag ID number, defect location, amount and type. This data file can be printed as a report or uploaded to plant LAN or any data storage device. The data in the roll map can be used to help identify the type of defect to be inspected and/or removed or to create custom reports for scrap. These reports aid in process improvement and scrap reduction programs.

Novation has been serving the printing and converting industries since 2002. They are a world leader in safety and waste reduction through the automatic marking and tracking of defects. Novation’s WebFlaggers have become an industry standard. Novation’s products have been an integral part of safety of waste management programs implemented by some of the world’s largest corporations. Their customers supply markets such as flexible packaging, electronics, automotive, films, tapes, non-wovens, healthcare and hygiene products and more. With almost two thousand installations worldwide, Novation’s equipment has marked hundreds of millions of defects. All Novation products are designed and manufactured in their plant in Bethlehem, PA.

Website: www.novation-inc.com

Phone: 610-837-5026