Return On Investment is the Primary Reason to Automate Your Cleaning

- Published: November 20, 2023

By Patrick Potter, President, Flexo Wash US

Capital investments generate value when their results are stable and predictable, leading to an overall increase in production and profit. Here is an overview of things to consider when calculating the Return on Investment on these expenditures.

Return on Investment (ROI) is a deciding factor when considering purchasing new equipment for your production line. Why is it the most important factor?

ROI calculation will not only tell you how fast your cleaning system will pay for itself, it will show you how you are actually losing revenue and profits by not purchasing this equipment.

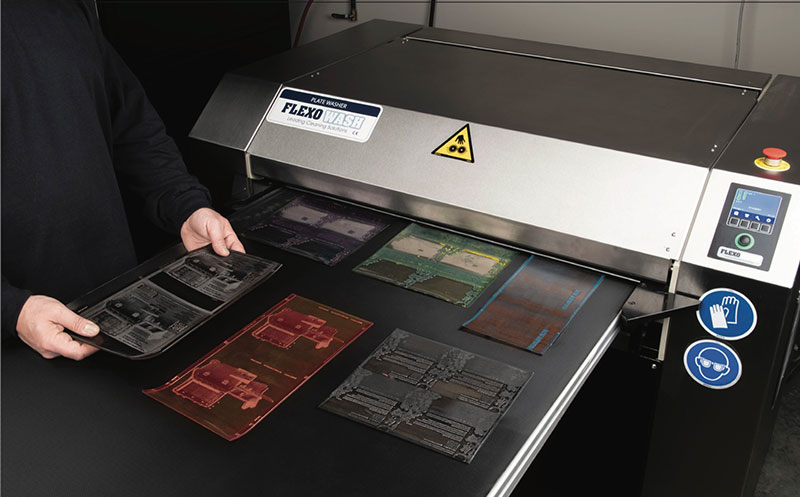

Investing in a cleaning system for your pressroom is a decision to automate a process. Automation brings immediate results: boosted throughput, faster turnaround times, shorter runs, improved quality and a labor savings.

The factors that affect the ROI are generally the same for each converter, but the details will vary depending on the machine.

What Affects the ROI?

There are several factors that affect the calculation of ROI, most of which boil down to quality control issues. A simple overview evaluation can uncover a lot of issues regarding your production, scheduling and cost operation. Here are a few things to consider when evaluating your production process:

- Labor expense — Good labor is hard to find, especially labor that is committed to manual cleaning all day. Automating positions formerly done manually by individuals frees those people up to do other, more valuable things in your pressroom.

Also, as printing presses modernize, jobs are more complex, runs are shorter and there are more changeovers in a day. How many changeovers you have in a day definitely impacts your cleaning. A backlog of dirty press parts makes changeovers that much harder. At the heart of the pressroom is people, making sure that all of these operations are occurring in line with your production schedule.

How much you spend on labor, and on all the variables that go with labor such as sick days, shortages, human error, etc. contribute to your bottom line.

- Cost of wasted material — Wasting materials on a project that has to be thrown out may not seem like a big expense, but all of these detract from your earnings in the long run. Materials such as substrate, ink, broken plates, damaged anilox rolls etc. are all elements that do not contribute to the finished product, thereby registering as a loss.

- Downtime — Downtime is a natural part of the production process for one reason or another. But, it is important to notice your downtime, how often it happens and how long it lasts. It is important to note your price per minute production cost — how much it costs for every minute you are down.

The Things You Cannot Measure

The primary result that you cannot measure is an increase in employee morale. Giving your employees the tools they need to succeed and meet goals is a sign of respect. Respecting your employees and letting them have ownership in their success is the best investment a company can make.

Time and time again, converters give the same feedback about automating their cleaning systems…

Tara Halpin, Steinhauser: “It is amazing how thankful our guys are to have these tools available to help them do their job more effectively.

“I cannot imagine running a print facility without one. The efficiency this creates for your press crews, the reduction in make-ready times, damaged plates and the appreciation you will get from your team makes it a no brainer.”

Todd Luman, Interprint: “The system has lasted due to our preventative maintenance program and a dedicated group of individuals (operators) who take pride in their work environment and respect the equipment they use.”

What Should You Do?

Calculating your ROI is a lot more than just plugging numbers into a formula. Each company has specific issues that contribute to their decision. Evaluating your pressroom points of pain related to labor, downtime and material costs will help pinpoint what system is best for you. Most importantly, giving your employees all of the tools they need to meet production goals will increase your profit and revenue stream for years and years to come, long after the ma- chine has paid for itself.

The Truth

Here is the truth that all businesses either know already or need to know about the future:

Whatever CAN be automated WILL be automated.

Makes sense, right? Workers are harder to come by but production needs to be maximized. Downtime is unacceptable and a huge liability. Businesses in the printing industry that formerly had full pressrooms of employees are a thing of the past. Automation is the future. Actually, automation is YOUR future.

This is better than the alternative, right? Nobody can afford to waste the manpower, the valuable time or the poor output of manual cleaning anymore. The market is too competitive.

The advantage to automation is that it is constantly innovating. For converters, they can decide how much automation they want for their business, ranging from printing processes to cleaning processes. Depending on their points of pain and what level of production they need to achieve, the level of their automation is in their hands.

About the Author

Ten years ago, Patrick joined his father Mike Potter and his brother Ryan Potter at Flexo Wash US. As President, he has been involved in growing the company to over 5,000 installations in 95 countries across the globe offering Leading Cleaning Solutions to their customers. A Louisville, Kentucky native and a graduate of Xavier University, Pat- rick is a board member of TLMI and is actively involved in the printing industry. Patrick can be reached at 888-493-5396.