Part Three of a Three-Part Series: Ultrasonic Drying of Biodegradable Molded Recycled Paper

- Published: September 16, 2024

By Gene Plavnik, President, Heat Technologies, Inc.

The first of this three-part series discussed a test program conducted by Heat Technologies, Inc.'s Spectra HE UltraTM drying system aimed at establishing optimized operating parameters of single-serving containers manufactured from recycled paper fiber suitable for food products with contained moisture. In the second and this third installment, major definitions of the related parties, the equipment, drying tests, quality control tests and data matrix utilized in this test program are shared.

Patented Commercial Scale Demo Ultrasonic Spectra HE Ultra Drying System

HTI's demo stand consists of an adjustable line speed conveyor from 3 m/min to 150m/min with the ability to have reciprocal motion, that is to have more dwell time under the dryer chest. There are four major components in the HTI Spectra HE Ultra drying system: 1) A three-slot based ultrasonic dryer chest; 2) An electric heater; 3) A regenerative blower; and, 4) A control panel to allow stable operation of the system. The moist air was discharged in the work zone, because the relatively small amount of evaporated water will not affect the quality of drying.

Drying Methodology and Procedure

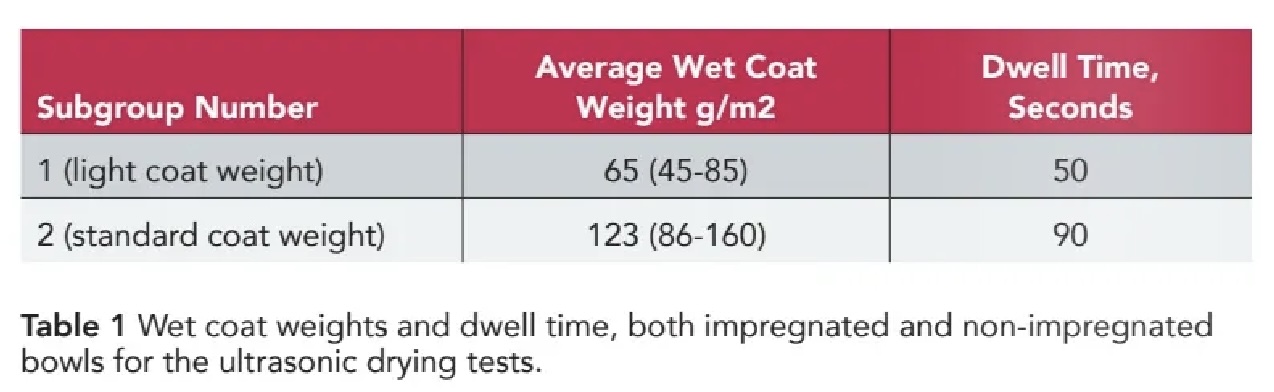

It was decided to divide the tests into two subgroups within each type of bowl. The first group had an average wet coat weight about 65 gsm per bowl and the second group had an average coat weight of 120 gsm per bowl. This was done based on our practical experience with sustainable and biodegradable packaging. This data is shown in Table 1.

Accuracy of Measurements

Following are major steps of the coating and wet/dry weight measurements. Each bowl was weighed three times: Initial base weight, weight of the wet coated bowl, weight of the bowl after the drying.

- Base weight, accuracy 0.1g.

- Weight of the coated bowl after the spraying with the emulsion, and after the drying - accuracy 0.1g.

- Linear dimensions of the bowl, 0.001m (or 1mm).

- Line speed, 0.1 m/min.

- Temperature of the bowls - 0.1C.

Dry coat weight was determined as a part of percent solids that the customer provided and laboratory proven measurements of the percent solids in the emulsion.

Each set of tests was conducted at identical operational conditions, such as the same amount of air, ultrasonic field, temperature of air, distance from jets to product.

The only difference in tests was dwell time, which represents the length of the ultrasonic dryer, based on its daily throughput. The throughput of 150,000-300,000 products in 24 hours was taken as a target.

Dwell time was accomplished by applying the reciprocating motion of the conveyor under the dryer with the same line speed. Previous experience in design and manufacturing of the drying systems for the single serve containers was taken into account to select the dwell time of the ultrasonic drying.

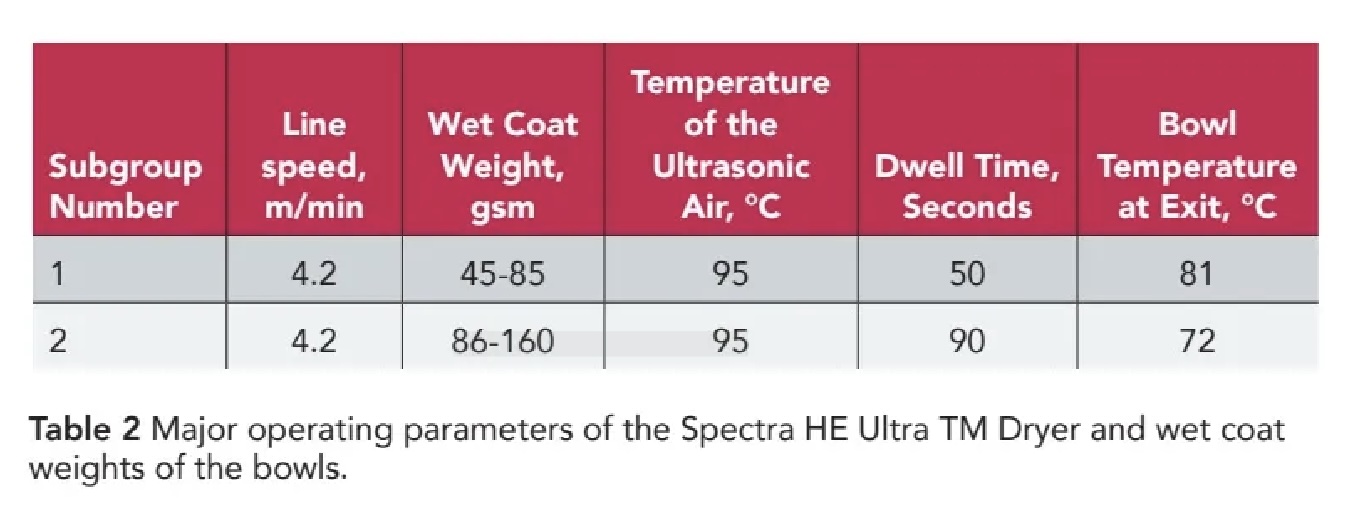

Both types of bowls, impregnated and non-impregnated, were coated and dried by the Spectra HE Ultra ultrasonic dryer module at the pre-established line speed, that was based on practical experience. The temperature of hot air was selected based on the restriction for the coating temperature not to exceed the bowl temperature at the end of drying.

Both coating and bowls should not exceed 85° C. The temperature of the ultrasonic air was installed at 95° C. High efficiency of the ultrasonically enhanced heat and mass transfer allows minimizing the difference of temperatures between the heated ultrasonic air and temperature of the bowls being dried. Based on the heavier coat weight, the dwell time for sub-group 1 was 50 seconds and for sub-group 2 was 90 seconds.

All tests were conducted at the same ambient temperature and relative humidity.

As stated, there is a necessity to compare HTT's ultrasonic drying technology with standard high velocity convective drying technology (hot air). This advanced convective drying technology is enhanced by strong ultrasonic oscillations of the heated air in to disrupt the boundary layer formed on the material and provide the process with advanced mass transfer rates. With the convective dryer, a high velocity convective oven was used.

Originally, the same temperature and dwell time on both dryers was set. However, the results of the weighing show that 90 seconds of dwell time at 95° C is not sufficient for complete drying of the coated bowls. Thus the dwell time was increased from 90 seconds (1.5 minutes) to 240 sec (4 minutes) to obtain comparable drying.

Results of the Cobb 1800 and MTR-WTR Tests and Complete Data Analysis

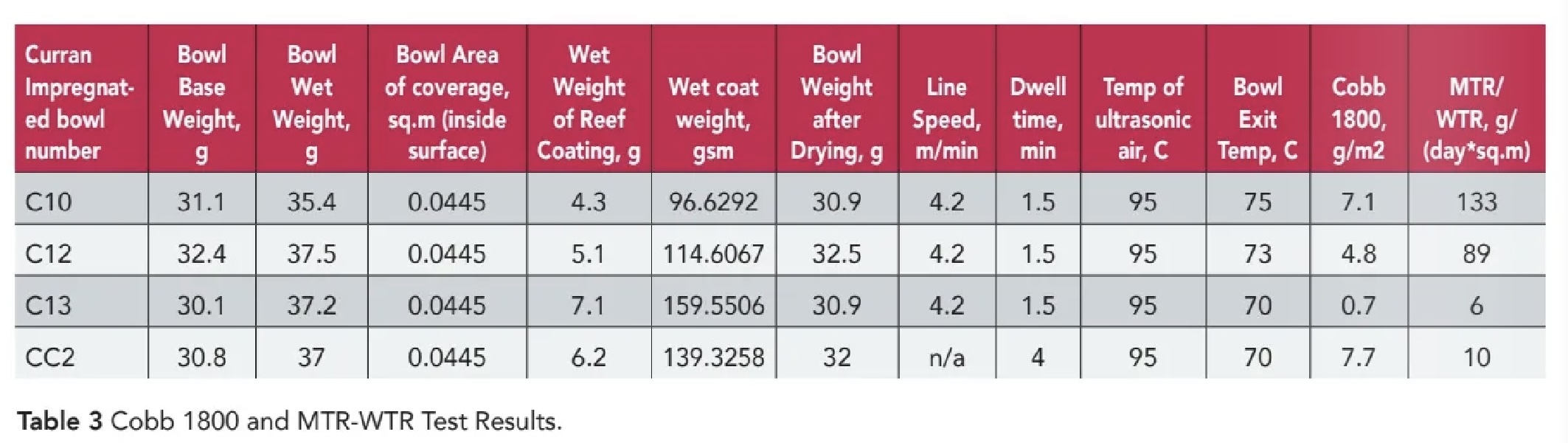

After completion of the tests, all dried bowls were vacuum packaged and shipped to the Danish Technological Institute for further analysis on water absorbency (Cobb 1800) 1800 seconds, and moisture transmission rate (MTR - total measurement intervals 3, time between the measurements 21.5 hours-22 hours-25 hours).

Bowls passing both tests were accepted as successful products that will withstand a plurality of food applications. Results of the drying tests as well as Cobb 1800 and MTR/WTR tests were tabulated and are presented in Table 3.

Operating Parameters of the Ultrasonic Spectra HE Ultra Drying System to Pass Both Tests

- Dryer footprint - 5.25 m long by 2.1 m wide at projected throughput 150,000 products/ 24-hour period.

- Projected Installed Power 700 kW, Operating Power - 420 kW.

- Operating temperature - 95°

- Line speed - 4.2 m/min.

Conclusions

- If an end user plans to implement production of biodegradable packaging and utilize coatings and/or pulp additives (e.g. Curran, Reef), particular tests on the permeability of the packaging material need to be considered. Further-more, a specific application may require different coating needs. Therefore, a combination of pulp additives and coatings may need to be taken into consideration.

- The wet coat weight of the barrier coating needs to be in the range of 100-160 gsm wet weight, at 30-40 percent solids.

- Other types of additives and barrier coatings were not investigated during this program.

- Spectra HE Ultra Drying system can be successfully utilized and can be of the footprint of 5.25 m long and about 2.1-4.2 m wide for a 150000-300000 products per 24 hours throughput.

- Ultrasonic drying can be most beneficial for production with a limited installation area due to its advanced removal of moisture rates (2.5 - 3 times higher, when compared with standard methods).

Sources:

Ultrasonic Spectra HE Ultra drying systems, Heat Technologies, Inc., www.heattechnologiesine.com.

Engineering and research services, Danish Technological Institute, www.dti.dk.

Products manufactured by Cellucomp Ltd., www.cellucomp.com.

About the Author

President at Heat Technologies, Gene Plavnik has more than 25 years of experience in the development, manufacturing commercialization of industrial and commercial heating and drying equipment for a variety of converting, packaging and paper industries. He is the author of nine U.S. and numerous European patents and holds a Master of Science Degree in Heat and Mass Transfer.