Special Report: Quality Protocols-Quality Assures Security

- Published: July 01, 2010, By By Nsenga Byrd Thompson, Associate Editor

Don Dobert, president and COO of ATL, manages his 52-year-old company with one important concept always at its center: Quality. With more than 40 years of engineering and fabrication experience, Dobert has dedicated his career to integrating comprehensive quality management systems to a host of manufacturing operations. But ATL's journey began some years before Dobert's leadership a decade ago.

Named for its original product line of advertising tape, Ad Tape & Label shifted gears in the mid-1980s, during the decline of the tape market. With expertise in pressure-sensitive applications, the company expanded its market and product line to specialize in customized labels for large printers and direct mail companies.

Known today as ATL, market focus now is divided into three divisions: Pharmaceutical Label and Disposable Medical Device; Security Label Systems; and Direct Mail and Product Label.

Although the Direct Mail and Product Label division was instrumental in broadening ATL's product line and is still a viable part of the business, the Pharmaceutical Label and Disposable Medical Device and Security Label Systems divisions have become the company's primary manufacturing focus.

Building in Quality

ATL's Pharmaceutical Label and Disposable Medical Device division provided huge growth for the company, and it played a major role in Dobert joining the company.

Dobert recalls when ATL came to him in 1999 to help the company achieve FDA compliance, his first objective was to change the company's mindset. “I told them, ‘You have to literally reinvent yourselves and formalize what you do. If you don't do that, you won't be able to provide the kind of clinical trial booklets you want.’”

Under Dobert's Advanced Product Quality Planning (APQP) for specifications, materials, tooling, control plans, performance qualifications, and batch inspection records, ATL has manufactured multipanel and multilingual booklet labels for the pharmaceutical industry for more than a decade.

According to Jeff Lord, security products manager, Dobert's unique mix of planning, engineering, production, and quality assurance has been critical in every aspect of ATL's operation, especially in the pharmaceutical booklet line.

“It's a combination of how both engineering and quality help to regulate one another and help support one another,” says Lord. “When we have our engineering team in the room, we have our quality assurance team in the same meeting. So it's designed for manufacturability.”

Dobert says keeping these strict quality protocols is very important since the company allows regular audits by top pharmaceutical companies for quality systems, validation protocols, and traceability of its products.

As an FDA-registered medical device manufacturer and one of fourteen 3M Medical Preferred Converters, custom disposable medical components are manufactured and shipped worldwide. ATL's services range from master roll distribution of medical foams and tapes to custom die-cut components with tight tolerances.

In a decade, ATL has executed more than 1,800 clinical trial runs, in more than 100 languages, that have yielded 120 million booklets with zero recalls.

It is a record that Dobert says makes him proud and allows ATL to differentiate itself from other label manufacturers.

“We don't consider ourselves a label house; we consider ourselves a manufacturer,” says Dobert. “We have a unique quality system because we deal with a lot of measurements. In the past ten years, we literally taught all of our personnel these APQP disciplines. And I think that's what separates us from 99 percent of the manufacturing houses and policies out there.”

Labeled for Security

The same custom engineering and quality assurance procedures executed in its Pharmaceutical Label and Medical Device division is evident in its Security Label Systems manufacturing, which provides the latest solutions in track and trace technology. Clients can choose from a broad selection of overt and covert label features, including invisible forensic taggents, holograms, color-shifting inks, and tamper-indicating materials.

Mass serialization capabilities, such as 2-D bar codes and custom codes, assist in supply chain management. ATL's “mix and rotate” approach combines multiple technologies in one label, changing with each production run.

With the complexity of security label solutions ATL provides, the company's quality management system is a crucial component to its production success.

Next Page: A Customized Experience

“Our quality system fits very well…with the level of complexity that [security label systems possess]. Companies need fast turnaround, and the accuracy has to be there,” says Lord. “You need to have this kind of quality system in place to prevent mishaps.”

As with the production in its Pharmaceutical and Medical Device division, there is a strong focus on engineering. “Pretty much everybody within the company is, in some capacity, involved in engineering. We are very engineering focused,” says Lord. “We have a new product development meeting scheduled daily.”

A Customized Experience

From conception to completion, ATL offers clients a customized experience, however, being able to provide such a customized solution is a complex and time-intensive process, Lord admits. Along with a thorough consultation, once the solution is ready to go into production, Lord says the setup time (which includes modifying and changing components to existing equipment) can take up to 20 hours.

“A lot of things we do are time intensive. But it's usually backed up with our quality systems,” he explains. “We can come in and audit your supply chain. So if it's a security feature, we can literally go into a hospital, determine their points of entry, and help them establish physical security, product security, loss prevention programs, and build a whole system.”

Building a complete solution is time well spent for ATL. When talking about this time commitment to clients, Dobert always comes back to the company's core focus on quality.

“Everything here is integrated with quality. Our operators have the freedom to stop presses. Our engineers have the freedom to call a new product development meeting at any time,” says Dobert. “The sooner you integrate your quality management system within all aspects of the organization, the sooner you get the psychological benefit — because people have the freedom to express their ideas — and you get the pragmatic benefit that you are making less mistakes.”

The complex mix of quality, engineering, and production is at the core of ATL. Or to keep things in the right perspective, Dobert describes what his company does with this crafty motto in mind: “If you can't find time to do it right, when will you have time to do it over?”

Converter Info

-

ATL | W140 N9504 Fountain Blvd.. Menomonee Falls, WI 53051 | 262-255-6150| www.atlco.com

Customized Converting Equipment

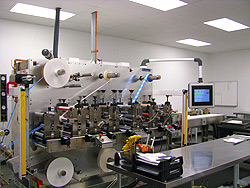

Whether it's a 35-panel pharmaceutical booklet or track and trace label, each job at ATL requires unique equipment capabilities that start with flexographic presses from Mark Andy and converting equipment from Delta Industrial Services. But, as Jeff Lord, security products manager, explains, the equipment did not end up the way it started.

“All the equipment is adapted for customers' needs,” he says. “So it might start out as a Mark Andy, and you may be able to recognize parts of it as Mark Andy, in actuality, 65 to 70 percent of the equipment probably has an add-on or pieces of equipment that are one-offs. They are designed by myself and our engineering team. We then work with MD Design and Automation, a fabrication shop up the street that will help us make any unique components. It looks contraptional, I will admit,” Lord laughs, “but it can produce.”

Supplier Info

-

Mark Andy | www.markandy.com

Circle 312 or visit www.freeproductinfo.net/pff -

Delta Industrial Services | www.deltamodtech.com

Circle 313 or visit www.freeproductinfo.net/pff -

MD Design & Automation | www.mddesignwi.com

Circle 314 or visit www.freeproductinfo.net/pff