A Secure Alternative

- Published: March 31, 2004, By Richard A. Steenblik, Nanoventions Inc.

Micro-optic films have been developed to respond to the ever-diminshing security provided by holograms and DOVIDs.

Holograms have been used to provide brand protection for many years, yet the reality is the security provided by embossed holograms is limited: conventional holograms are counterfeited easily.

Hologram counterfeiters have a number of options: optical re-origination, optical copying, physical replication, and simulation. Counterfeiting of a security hologram by optical re-origination requires the greatest capital investment and highest level of technical capability. Research has focused on thwarting this method by increasing the sophistication of the original. The most sophisticated of these are computer-generated Diffractive Optical Variable Image Devices (DOVIDs) (see PFFC's August 2002 issue for a detailed explanation of DOVIDs). Exact re-origination of a sophisticated DOVID is a daunting task, but exact reorigination usually is unnecessary.

Optical copying presents a second method of counterfeiting a hologram or DOVID by making a holographic image of the original. Depending on the complexity of the original, it may be necessary to make the counterfeit using multiple exposures from a range of reference beam angles, but a passable copy can be created with effort.

Physical replication presents a more direct route to a passable counterfeit. Holograms, diffractive DOVIDs, and other single-surface embossed diffractive optics are susceptible to this attack because they all bear a very shallow microstructure, typically in the range of one-quarter to one-half micron in depth. This microstructure can be exposed and physically copied to make a manufacturing tool. This method of attack is effective regardless of the optical complexity of the hologram or DOVID. Limited protection from physical replication can be achieved by patterned metallization and by the use of frangible materials, but these approaches do not prevent counterfeiting by optical copying methods.

Embossed holograms produce their effects by diffraction; they typically look shiny, silver, have some kind of image or text, and flash in rainbow colors when moved. Few people look for more than this when they make the effort to authenticate a hologram, so counterfeiters often can get by with a crude simulation.

The shiny metallic appearance of embossed holograms can be simulated by using a patch of a different commercially available hologram, by printing images over decorative diffraction film, or even by using plain aluminum foil. Upon casual inspection, people will not notice the usual holographic image content is missing. The hard truth is embossed holograms no longer are effective overt authentication devices — they are too easy to counterfeit and simulate, and their range of visual effects is too limited. People don't look for subtle, or not so subtle, details that differentiate the authentic from the counterfeit.

Micro-Optics: THE Next Generation

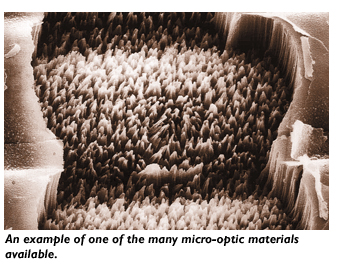

Several years ago, alternative optical security films based on geometrical optics were developed. Geometrical micro-optic films use non-diffractive optical elements to achieve their effects. It was determined a large improvement in counterfeit deterrence could be gained by the use of high-precision micro-optics and microstructures having a surface relief greater than a few microns, and a seemingly unlimited range of optical effects could be obtained from micro-optic systems incorporating lenses, mirrors, and images created at a minute scale. (See picture above.)

Geometrical micro-optic security films have additional counterfeit resistance because their production requires proprietary manufacturing methods: Conventional holographic reproduction processes, typical of hologram counterfeiting operations, are inadequate to reproduce the structure and function of these micro-optic elements. A proprietary mastering, tooling, and manufacturing process has been developed that can create and replicate these complex surface relief micro-optics at a reasonable cost.

A line of security films has been developed to respond to the ever-diminishing security once provided by holograms and DOVIDs. These films produce strong, visually compelling effects while providing high resistance to counterfeiting and simulation. The film is a synthetic imaging material — millions of minute image projectors built into the film act in unison to create color-stable, eye-catching images that appear unlike any hologram. These security films are all polymer and do not contain any metal.

These micro-optic films have high counterfeit resistance for two reasons — physical complexity and unique manufacturing requirements. They are physically complex because the micro-optic image projectors include multiple optical elements created at different levels within the film. Each of these elements must be present in the right relationship to the other optics to produce the special effects. These coordinated layers of optical elements are fused into a solid polymer film that can't be disassembled to get to the internal optical elements.

This presents a huge barrier to counterfeiting because it defeats the physical replication attack. Because geometrical micro-optic film is not based on diffractive optics, the visual effects provided cannot be mimicked or copied by any kind of hologram, so the optical copying attack is defeated. Neither holograms nor lenticular film materials can simulate the visual effects of a micro-optic film convincingly, so attack by simulation is thwarted, too.

The remaining potential attack is by re-origination. This is probably the greatest barrier to counterfeiting, since it would involve the need to recreate proprietary origination, tooling, materials, and manufacturing methods.

A Variety of Images

Micro-optic films present visually compelling images that can be seen over a wide field of view, in any orientation, under virtually any lighting. These films are overt security devices — their effects are visible to the naked eye without any additional viewing or detecting apparatus.

Unlike embossed holograms, micro-optic films do not appear metallic, and they can be either transparent or opaque. Transparent films present dynamic images that coexist with underlying print images without obscuring them. These films can be manufactured with a thickness of less than one mil, thus facilitating their application to product packaging, labels, security documents, and currency paper.

While the goal was to create a high-security material, micro-optic films have proven to be much more. The visual effects they create are engaging and fun! The brand enhancement value provided by micro-optic film may be as important as the security it provides, because it has the effect of teaching consumers what to look for automatically.

Micro-optic security films create compelling visual effects: The images look like printed graphics that are doing impossible things. Imagine taking a credit-card-sized piece of one-mil-thick micro-optic film and laying it down on a newspaper page. The first thing you'll notice is that you still can see the newsprint and photos clearly, but now there are micro-optic images, too. These appear solid and dense, but they don't block the print from being seen — and they are doing impossible things. Exactly what they are doing depends on the type of micro-optic films being used.

Some security films present images that appear beneath the printed surface, like a background pattern that lies a quarter- or half-inch behind the print. This deep image is visually really there: When you look at these images from different angles, you will see them move with respect to the newsprint (called parallax shift), just like they are beneath the paper.

Other security films create images that appear much deeper — inches deep. Instead of creating a background pattern, this image is the center of attention and shows correct parallax shift from different angles. Applied to the face of a box, it can give the appearance that you are seeing through the front of the box to the inside of the back surface — the box can look empty even though it is full!

Another film creates images that float above the print. The effect is similar to the mental image people have of what a “real” hologram should look like — much like the Leia Organa floating hologram in Star Wars.

The deep and float effects can be combined; when viewed in one orientation the images appear deep, but when rotated 90 deg, the images levitate from deep into float.

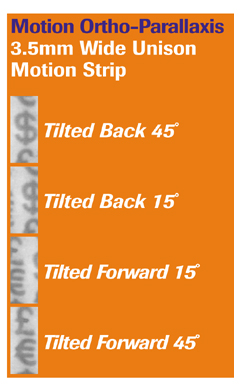

Motion security films create images that lie in the plane of the material but move in a strange, fluid way — the image motion is always at right angles to the direction you naturally expect. If you tilt the top of the piece away from you, the images slide to the left or right. If you tilt the piece left and right, the images slide up and down. This effect (technically called “ortho-parallaxis”) is unique — a ribbon of motion security film can be narrower than the image it creates, yet the whole image can be “scrolled” through the width of the thread by tilting it. (See figure at right.)

But wait, there's more: a single micro-optic film can incorporate the variety of effects in virtually unlimited combinations.

History suggests that no anti-counterfeit technology provides security in perpetuity; rather, effective anti-counterfeiting usually requires a moving target. Micro-optic security films provide a new tool in the fight to secure documents and products from counterfeiting.

Richard A. Steenblik is co-founder of Nanoventions, Roswell, GA, USA, and serves as chief technical officer. He has 26 years of experience in optical invention and innovation. From 1989 to the present, he specialized in the development of novel micro-optic flms, with emphasis on high-security and anti-conterfeiting materials. He can be reached at 678/366-5929; sales@nanoventions.com.

The views and opinions expressed in Technical Reports are those of the author(s), not those of the editors of PFFC. Please address comments to author(s).