Keeping Score

- Published: June 30, 2004, By Edward Boyle, Contributing Editor

Using incentives to motivate employees pays off for Consolidated Label, named "Best Managed Company" by TLMI.

Struggling through a difficult economic environment, many converters have focused on cost-cutting as a primary way of maintaining a healthy bottom line. Not Consolidated Label Co.

While the Longwood, FL-based label converter does keep a keen eye out for wasteful spending, president Joel Carmany says his company’s success primarily comes from being “top-line oriented. We’re focused on getting the sales first, getting the shipments to match up with the sales dollars, and everything else—except for quality, of course—is secondary to that.”

The numbers speak for themselves. When Carmany purchased the company in 1984, it had just six employees and $225,000 in annual sales. Today, Consolidated, along with its subsidiary Online Labels, has 85 employees and sales of $20 million. Even more impressive, the company had just $6 million in sales ten years ago.

In recognition of its efforts, Consolidated Label recently won the prestigious “Best Managed Company” award, given annually by the Tag & Label Manufacturers Inst. (TLMI), for the second consecutive year. That’s no easy task, considering TLMI’s membership includes many of the nation’s premier label converters.

The TLMI Ratio Study, which is the basis for the “Best Managed Company” award, evaluates a company’s performance in a number of critical business areas, including the cost of goods sold, selling expenses, net operating income, sales per employee, inventory turnover, and more. The study provides industry “benchmarks” that allow label converters to gauge their own performance in nearly a dozen categories year-over-year and in comparison to their peers.

Productivity and Accountability

Carmany says a critical reason for his company’s success has been attracting entrepreneurial-minded employees at all levels of company—from the pressroom to customer service—who are rewarded for their success and held accountable for their mistakes. All company employees receive a monthly bonus based on Consolidated’s overall sales success; press operators are rewarded for exceeding goals for productivity, based on dollar volume. At the same time, they can be penalized for rejected material, both in-house and customer returns. It’s what Carmany describes as the basic “carrot and stick” approach. The pressroom has a “scoreboard” that tracks each operator’s activity level for the week. Not surprisingly, productivity inevitably picks up at the end of the odd month when the earlier numbers don’t appear to be reaching “bonus” level. And, says Carmany, that’s the whole point.

“It’s kind of like the Masters golf tournament,” explains Carmany. “They want to post a good number on the board. You look at the board to see how you’re doing, so you can track your progress against other people. Based on how well they do against the monthly goal, the entire company will receive a bonus on sales-dollar shipments out the door. A lot of people don’t disclose that type of information; we publicize it.

“The thing I’ve always found, and it’s very simple, is that you can talk to people, you can write memos, you can have meetings. But when you affect their back pocket, you’ll affect their performance,” explains Carmany. “And I think that’s been the key [to the success] of the programs that we have here.”

Sales aside, Consolidated also “gets excellent press utilization,” through a unique production schedule: two 10-hr shifts each day Monday through Thursday and two 12-hr shifts Friday, Saturday, and Sunday. Perhaps because of its work schedule, which gives each pressman a minimum of three days off per week, the company has no shortage of applicants to run its nine presses.

That gives Consolidated the luxury of hiring only the most skilled and motivated employees who also fit in well with the company’s “top-line” philosophy. Consolidated puts each of its prospective press operators through a two-day “press trial” to determine their proficiencies and subsequently hires just one of three applicants.

“We don’t interview someone and say, ‘Boy, we think you’d make a good pressman,’” says Carmany. “I think a big part of performance obviously starts with talent, and there’s only one real way to determine that and that’s by seeing them run the press before a job offer takes place.”

Workhorse Presses

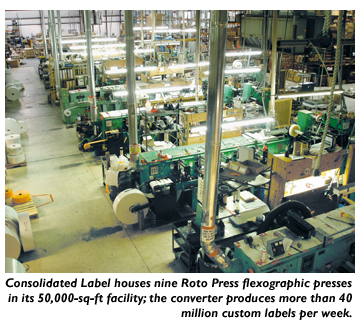

Consolidated operates nine Roto Press (now Nilpeter) flexo presses in its 50,000-sq-ft facility, including six 10-in., two 13-in., and one 16-in. model. They print as many as ten colors, and some units are equipped for hot stamping. Carmany says as a small company two decades ago, he found Roto Press presses to be both economical and productive. He also cited low maintenance costs and “fairly quick changeovers” as other benefits.

“First of all, they’re real workhorses,” he explains. “They’re heavy-duty presses. They were very competitive with other presses (in terms of quality), but they were less expensive, which was one of the main drivers at the time. We wanted something that could put out competitive quality at a lower initial cost. And they’ve gotten a lot better, so we stuck by them. It’s been a good marriage, really.”

Consolidated is described as one of the largest label converters in the Southeastern US, which is home to a majority of its repeat customers as well. The company does, however, serve more than 5,000 end-users across the US, with food, health and beauty, household products, and medical as its primary markets. A direct sales force serves customers in the Southeast; brokers, sales representatives, and a dedicated in-house service department handle the rest of the country. In all, the facility produces more than 40 million custom labels per week.

In spite of its size, the company accepts minimum orders of just 1,000 labels—without using a digital press. Carmany notes that was an average order size when he bought the company, and he says Consolidated still can produce such small orders both economically and profitably by using some of its 10-in. presses with quick-change capabilities and operators who are skilled at efficiently producing small runs. Careful preparation also is key, with plates being pre-mounted and inks, dies, and other components ready when the press is.

“It’s all about tempo and knowing in advance what the operator’s going to run so he can set up efficiently,” Carmany says of the system. “If a guy’s doing small jobs—$300 to $400 each—then he’s going to do maybe ten of those a day. That’s the key to success” for short runs.

In addition to Consolidated Label, the company also operates a subsidiary, Online Labels, that produces blank thermal transfer labels. As its name suggests, the operation is largely Internet-driven but has proven to be a profitable complement to Consolidated’s custom label business.

“At the end of the day, your reputation usually precedes you in the marketplace,” notes Carmany. “We’ve been very consistent over the last 20 years. We’ve been able to grow even when the markets were somewhat flattened out. This is due to the commitment of our people, and the fact that the Southeast has seen stronger growth than some other areas of the country.

“Year after year, we’ve continued to invest in our plant and our equipment so we could stay on top of the curve. As our customers grew, we were there with more capacity to serve them, and that’s a big factor. My view is you have to make the pipe a lot bigger today than you did even five years ago, because the demands are a lot greater, and people expect things that they didn’t expect five years ago. So you have two choices: You can meet the demand, or you can say goodbye to the customer.”

Apparently, the company has “managed” to meet those expectations quite well.

Converter Info

Consolidated Label Co.

925 Florida Central Pkwy.

Longwood, FL, USA 32750

407/339-2626; consolidatedlabel.com

Supplier Info

Nilpeter USA; nilpeter.com